Preparation method of BCN nano amorphous phase toughened TiB2-B4C composite ceramic

A technology of tib2-b4c and multi-phase ceramics, which is applied in the field of high-performance structural ceramics preparation, can solve the problems of high brittleness, difficulty in sintering and densification of finished products, and low diffusion rate, so as to prevent crystallization, reduce sensitivity, and high sintering efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

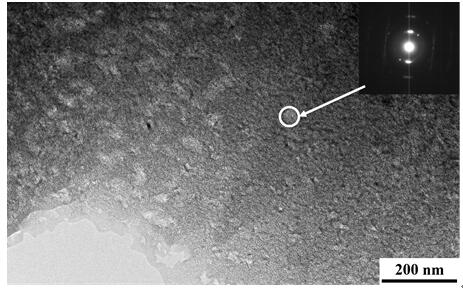

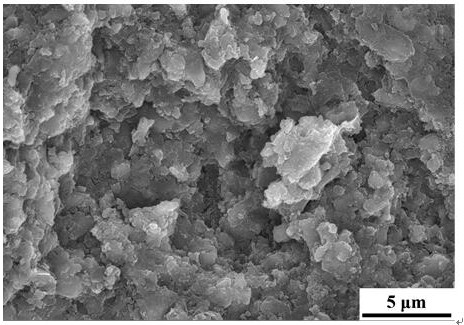

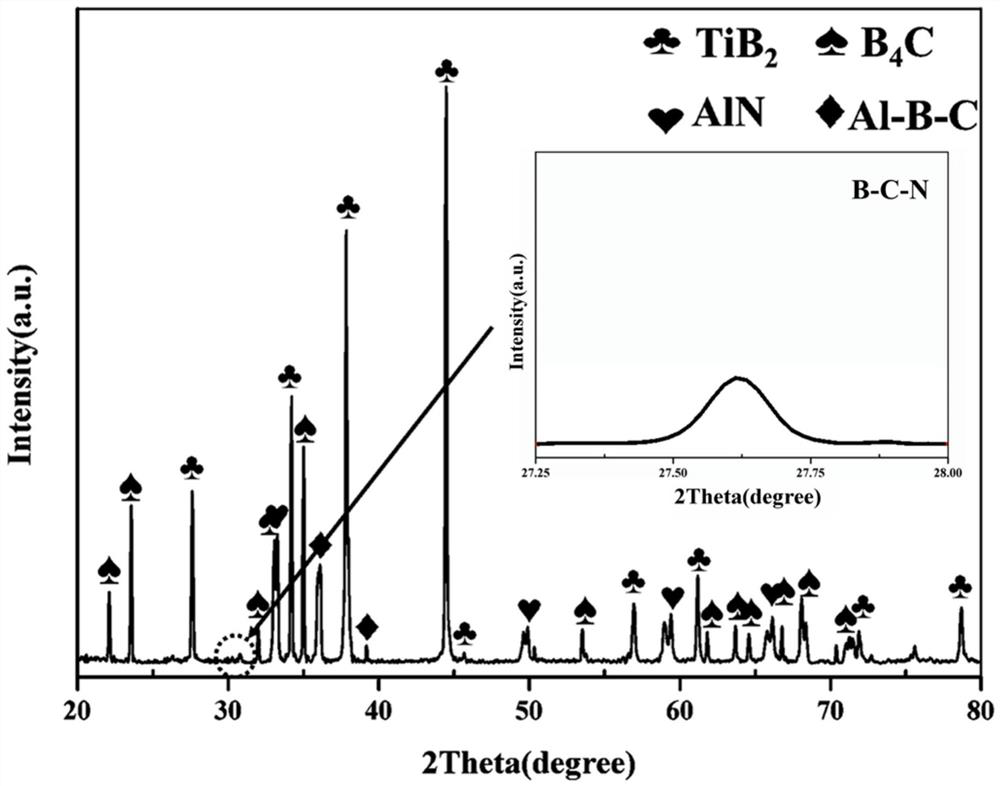

Embodiment 1

[0025] Aluminum nitride powder (average particle size 1 μm), boron carbide powder (average particle size 3 μm), metal Ti powder (average particle size 5 μm), metal aluminum powder (average particle size 2 μm), polyethylene Glycol (molecular weight 2000) and ethanol are mixed according to the mass ratio of 1:7:2:0.1:0.2:20, in which Al powder is used as sintering aid and reactive agent, and stirred for 1 hour to obtain a mixed slurry; then the mixed slurry Put it into a polytetrafluoroethylene tank for ball milling for 24 hours, the ball milling rate is 300r / min, and the ball milling medium is zirconia balls. After ball milling, the slurry is sieved to obtain a mixed slurry; the slurry is dried in a vacuum oven at 80°C for 8 hours, and then The multi-phase ceramic powder was obtained by sieving; the multi-phase ceramic powder was placed in a graphite mold, sintered and kept at 1720°C for 6 minutes in a vacuum, and the heating rate was 120°C / min. The resulting BCN nano-amorphous...

Embodiment 2

[0027] Aluminum nitride powder (average particle size 1 μm), boron carbide powder (average particle size 3 μm), metal Ti powder (average particle size 5 μm), metal aluminum powder (average particle size 2 μm), polyethylene Glycol (molecular weight 2000) and ethanol are mixed according to the mass ratio of 1:7:2:0.2:0.2:20, in which Al powder is used as sintering aid and reactive agent, and stirred for 1h to obtain a mixed slurry; then the mixed slurry Put it into a polytetrafluoroethylene tank for ball milling for 24 hours, the ball milling rate is 300r / min, and the ball milling medium is zirconia balls. After ball milling, the slurry is sieved to obtain a mixed slurry; the slurry is dried in a vacuum oven at 80°C for 8 hours, and then The multi-phase ceramic powder was obtained by sieving; the multi-phase ceramic powder was placed in a graphite mold, sintered and kept at 1670°C for 5 minutes in a vacuum, and the heating rate was 100°C / min. The resulting BCN nano-amorphous pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com