Multifunctional composite lubricating grease and preparation method thereof

A grease, multi-functional technology, applied in the field of lubricants, which can solve problems such as low drop point of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

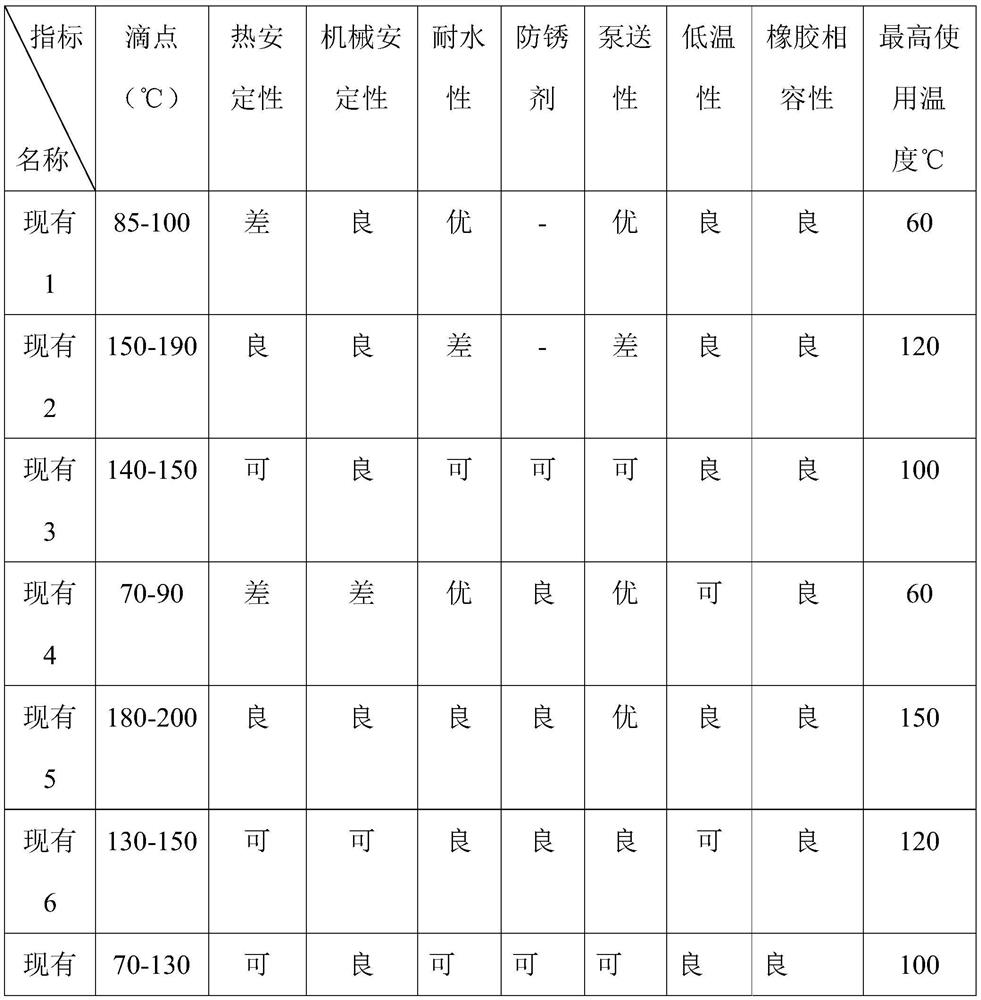

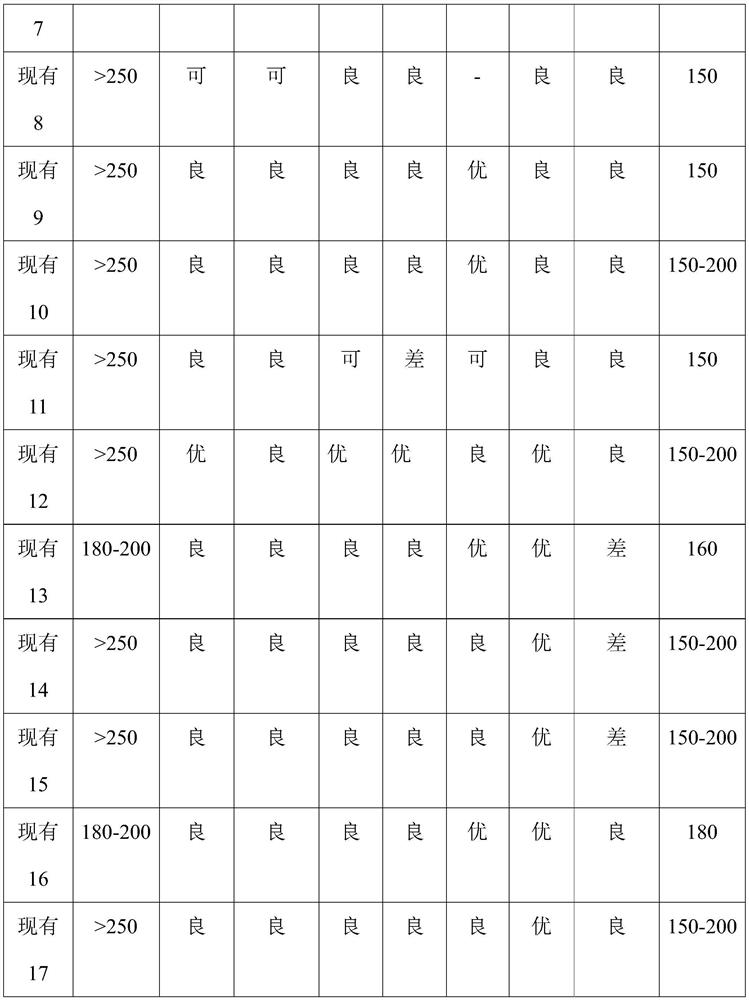

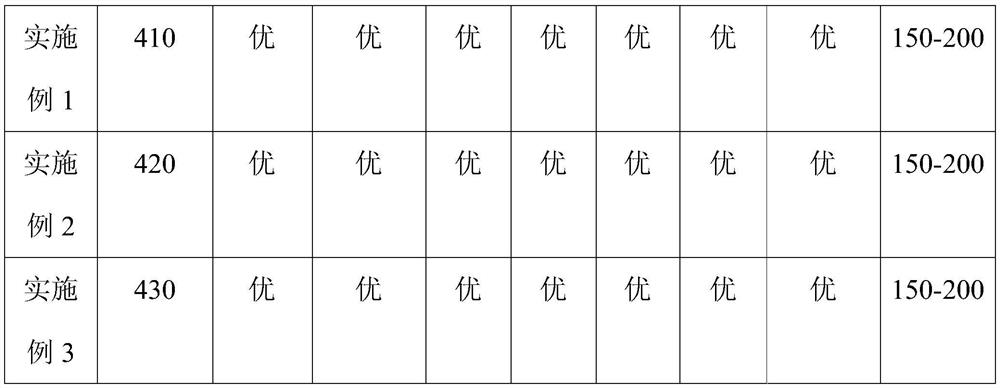

Image

Examples

preparation example Construction

[0020] A preparation method of multifunctional composite grease, comprising the following steps:

[0021] S1 After mixing the fatty acid and oil, add a strong alkali aqueous solution to perform a saponification to obtain the first paste. When adding the lye, add it slowly. This process is carried out in a high-speed shearing machine in the reactor;

[0022] S2 Adding base oil to the paste, performing secondary saponification by cyclic shearing, to obtain a second paste, which is viscous, silky, uniform and free of particles; this process is carried out in a high-speed shearing machine in a reactor;

[0023] S3 Adding organic bentonite, anti-wear agent, anti-rust agent, stabilizer and extreme pressure agent to the second paste, and cyclically shearing to obtain the multifunctional compound grease. This process is carried out in a high-speed shearing machine in a reactor.

Embodiment 1

[0025] Preparation of Multifunctional Compound Grease

[0026] S1 Weigh 5kg of fatty acid, 10kg of animal and vegetable oil, 12kg of sodium hydroxide aqueous solution, 5kg of organic bentonite, 2kg of nano-polytetrafluoroethylene, borate, triethanolamine and barium petroleum sulfonate to obtain rust remover 0.1kg, glycerin and hydrogen Stabilizer 0.1kg obtained by mixing sodium oxide, T306 5kg and mineral oil 10kg;

[0027] S2 Put the fatty acid and oil into the reaction kettle and stir evenly. After stirring, add an aqueous sodium hydroxide solution with a mass fraction of 30% for saponification to obtain the first paste. Add the aqueous sodium hydroxide solution slowly;

[0028] S3 adding mineral oil to the paste, performing secondary saponification by cyclic shearing, to obtain a second paste, which is viscous, uniform and particle-free;

[0029] S4 Add organic bentonite, nano-polytetrafluoroethylene, antirust agent, stabilizer and T306 to the second paste, and cyclic shea...

Embodiment 2

[0031] Preparation of Multifunctional Compound Grease

[0032] S1 Weigh 10kg of fatty acid, 25kg of animal and vegetable oil, 18kg of sodium hydroxide aqueous solution, 15kg of organic bentonite, 5kg of nano-polytetrafluoroethylene, borate, triethanolamine and barium petroleum sulfonate to obtain rust remover 0.3kg, glycerin and hydrogen 0.15kg of stabilizer obtained by mixing sodium oxide, 6kg of T306 and 31kg of mineral oil;

[0033] S2 Put the fatty acid and oil into the reaction kettle and stir evenly. After stirring, add an aqueous sodium hydroxide solution with a mass fraction of 30% for saponification to obtain the first paste. Add the aqueous sodium hydroxide solution slowly;

[0034] S3 adding mineral oil to the paste, performing secondary saponification by cyclic shearing, to obtain a second paste, which is viscous, uniform and particle-free;

[0035] S4 Add organic bentonite, nano-polytetrafluoroethylene, antirust agent, stabilizer and T306 to the second paste, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com