Alkane dehydrogenation heating auxiliary agent, preparation method and application thereof

A heating aid, alkane dehydrogenation technology, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of difficult reduction, poor hydrothermal performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of an alkane dehydrogenation heating aid, comprising the following steps:

[0030] S1: Calcium oxide or calcium hydroxide or a mixture of both, CuO or copper hydroxide or copper carbonate or basic copper carbonate or a mixture of at least two, Al 2 o 3 Or aluminum hydroxide or a mixture of the two, add water to knead evenly to obtain a kneaded product;

[0031] S2: Drying and calcining the kneaded product in sequence;

[0032] Preferably, the kneaded product can be extruded into strips or pelletized before drying, preferably extruded into strips; then dried and calcined in sequence, the drying temperature is 80-110°C, preferably 100°C, and the calcining temperature is 900°C -1200°C, preferably 1100°C, the calcination time is 3-4 hours, preferably 4 hours.

[0033] The exothermic additive for alkane dehydrogenation can be used as an exothermic additive in the dehydrogenation process of low-carbon alkanes.

Embodiment 1

[0055] Pseudoboehmite (containing 0.07 kg of alumina), calcium hydroxide (containing 0.68 kg of calcium oxide), and 0.25 kg of copper oxide were placed in a kneader and mixed evenly, and kneaded by adding water. After the kneading is completed, it is placed in an extruder to extrude, and the extruded sample is dried at 100° C. for 4 hours. The dried sample was then baked at 1100°C for 3 hours. The sample was named REZEL-1. The heat release before and after hydrothermal treatment is shown in Table 1.

[0056] REZEL-1 was aged at 800°C and 100% hydrothermal for 48 hours, and the sample was named Steam REZEL-1.

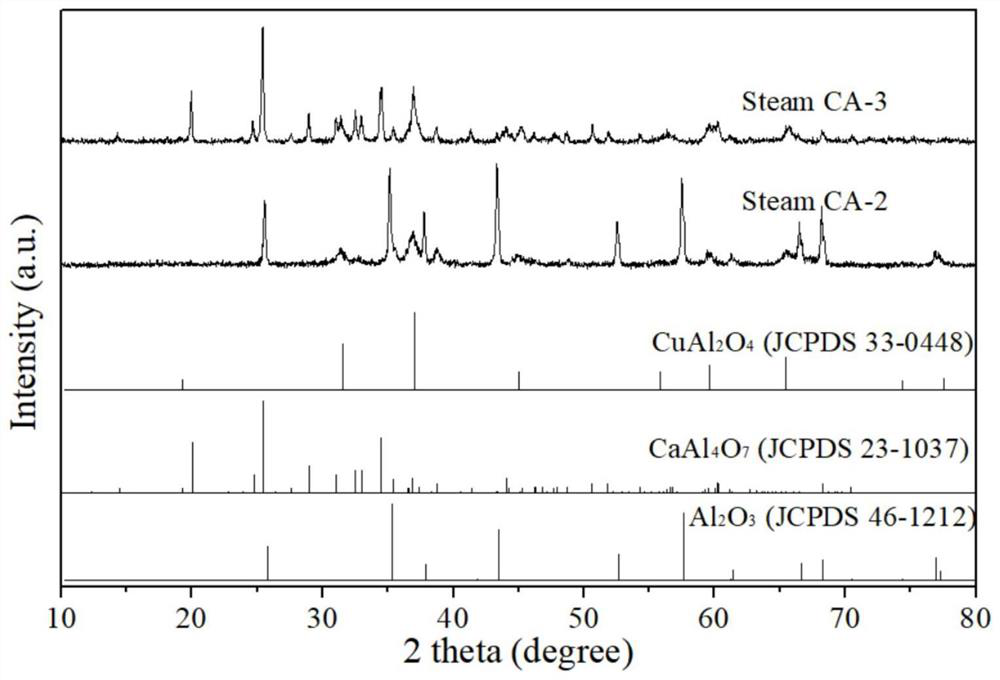

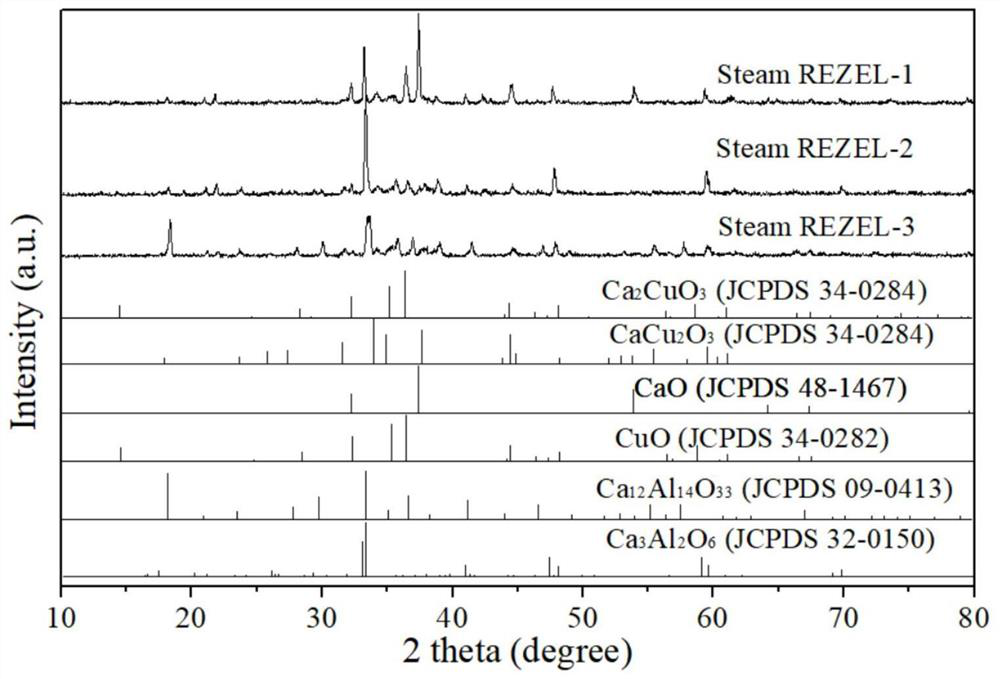

[0057] For the XRD pattern of Steam REZEL-1, see figure 2 , Steam REZEL-1 is black, see the DSC curve of REZEL-1 before and after hydrothermal aging Figure 4 .

Embodiment 2

[0059] Pseudo-boehmite (containing 0.16 kg of alumina), 0.53 kg of calcium oxide, and 0.25 kg of copper oxide are placed in a kneader and mixed evenly, and kneaded by adding water. After the kneading is completed, it is placed in an extruder to extrude, and the extruded sample is dried at 110° C. for 4 hours. The dried sample was then baked at 900°C for 4 hours. The sample was named REZEL-2. The heat release before and after hydrothermal treatment is shown in Table 1.

[0060] REZEL-2 was aged at 800°C and 100% hydrothermal for 48 hours, and the sample was named Steam REZEL-2.

[0061] See the XRD pattern of Steam REZEL-2 figure 2 , Steam REZEL-2 is black, see the DSC curve of REZEL-2 before and after hydrothermal aging Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com