Anti-icing/deicing composite material and preparation method and application thereof

A composite material and composite film technology, applied in the field of anti-icing/de-icing composite materials and their preparation, can solve the problem of inability to maintain de-icing/anti-icing performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

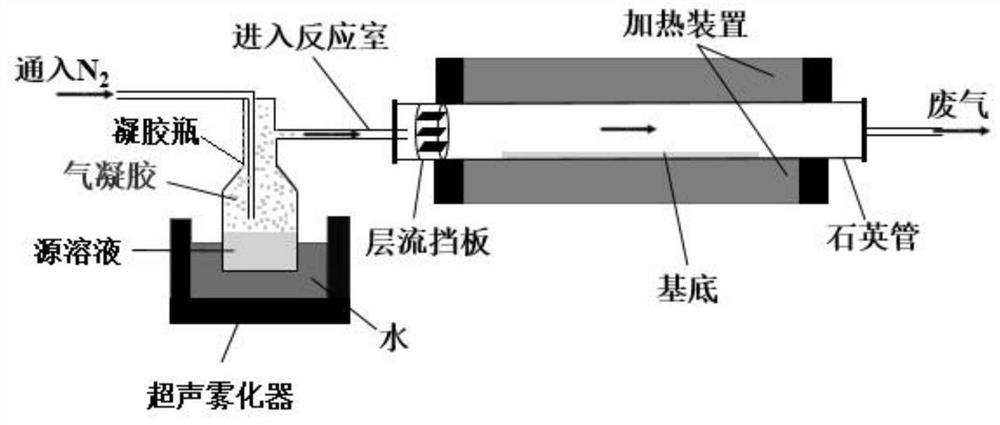

[0035] The present invention also provides a method for preparing the anti-icing / de-icing composite material described in the above technical solution, comprising the following steps:

[0036] Mixing an organic titanium source, an organic carbon source and an organic solvent to obtain a source solution;

[0037] gelling the source solution to obtain a gel system;

[0038] The gel system is deposited on the surface of the substrate to be deposited by using airgel-assisted chemical vapor deposition to obtain an anti-icing / de-icing composite material.

[0039] In the present invention, unless otherwise specified, the raw materials used are all preferably commercially available products.

[0040] The invention mixes the organic titanium source, the organic carbon source and the organic solvent to obtain the source solution.

[0041] In the present invention, the organic titanium source preferably includes one or more of titanium isopropoxide, isopropyl titanate, ethyl titanate a...

Embodiment 1

[0061] A method for preparing a carbon-doped titanium dioxide film, comprising the steps of:

[0062] 1) First wipe the substrate with absorbent cotton dipped in acetone, then ultrasonically clean it in acetone, absolute ethanol, and three times of distilled water for 10 minutes, then immerse it in piranha solution at 80°C for 1 hour, and then ultrasonically clean it in three times of distilled water 5min, put into the reaction chamber after drying.

[0063] 2) Ultrasonically disperse titanium isopropoxide and acetylacetone (power 250W, time 10min) in toluene to obtain a mass percent concentration of titanium isopropoxide of 5.51wt% and a mass percent content of acetylacetone of 0.387wt%. source solution; feed nitrogen gas (flow rate 0.6L / min), discharge the air in the airgel-assisted chemical vapor deposition device, set the heating rate of the reaction chamber to 10°C / min, and the target temperature to 450°C, after reaching the reaction temperature Turn on the ultrasonic at...

Embodiment 2

[0070] The only difference from Example 1 is that the mass percentage of acetylacetone in the source solution is 1.12wt%.

[0071] The mass content of carbon in the carbon-doped titanium dioxide film was measured by X-ray photoelectron spectroscopy to be 67.1%.

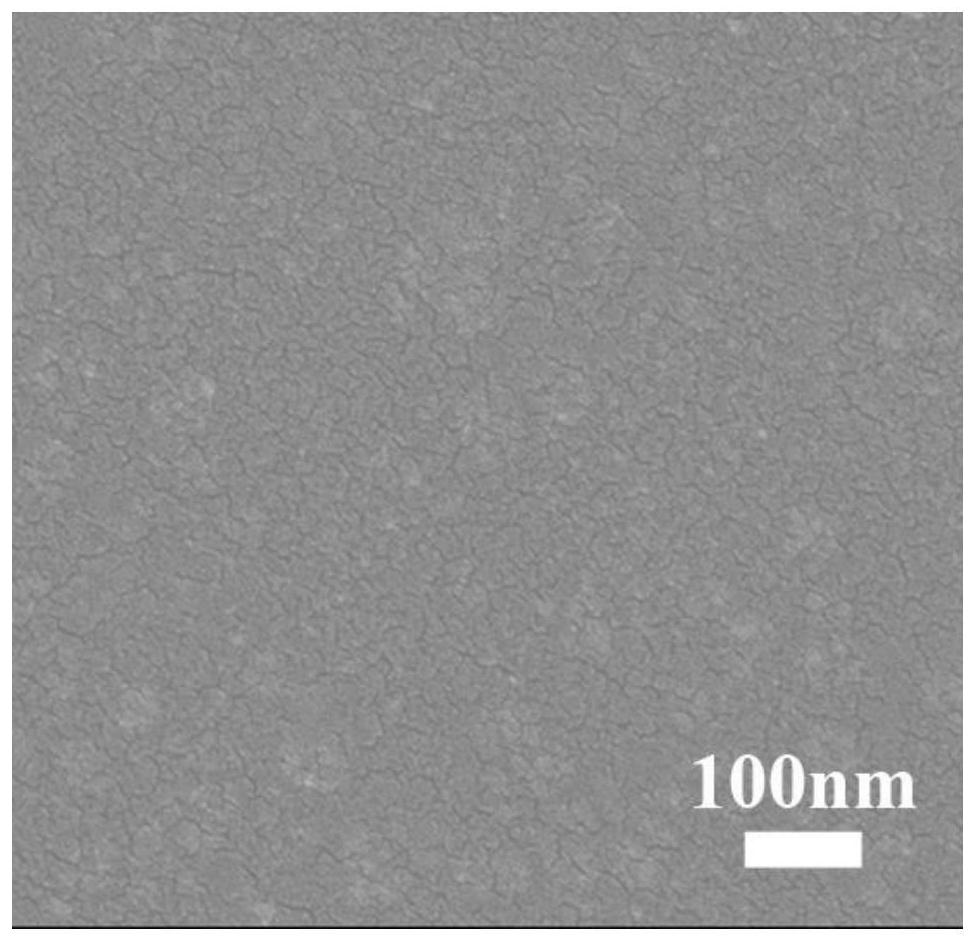

[0072] The surface and cross section of the obtained carbon-doped titanium dioxide film were observed with a JSM-7610F field emission scanning electron microscope, the results are as follows Figure 5 and 6 shown. From Figure 5 and 6 It can be seen that the surface of the obtained carbon-doped titanium dioxide film is nano-scale spherical particles uniformly distributed, and the thickness is 3.1 μm.

[0073] Adopt X-ray energy spectrum (EDX) to measure the chemical composition of gained carbon-doped titanium dioxide film section, the result is as follows Figure 7 Shown, wherein, (b) figure is the X-ray energy spectrogram of (a) figure 1. From Figure 7 It can be seen that the point-scan section of the X-ray e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com