Antistatic polyurethane protective film and preparation method thereof

A polyurethane, protective film technology, applied in the direction of polyurea/polyurethane adhesive, pressure-sensitive film/sheet, film/sheet adhesive, etc., can solve the problem of low viscosity, high exhaust and no white fog. , Affect the performance of PU pressure-sensitive adhesives, the exhaust performance is not ideal, etc., to achieve good self-exhaust performance, lasting antistatic effect, and good adhesion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

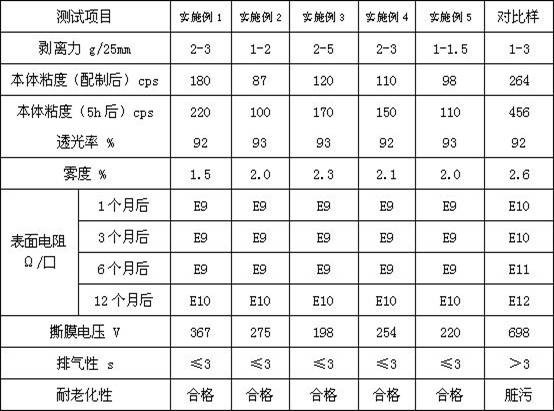

Examples

Embodiment 1

[0037] S1, the preparation of polyurethane pressure-sensitive adhesive: According to the mass ratio, polyurethane resin slurry PU-1 (viscosity 12000, weight average molecular weight 90000, solid content 66%), 100 parts, EA: 150 parts, TDI: 6 parts, triethylene Sodium diamine-2-ethylhexanoate (TEDA-EH) delayed catalyst: 0.02 parts; tributylmethylammonium bis(trifluoromethanesulfonyl)imide salt antistatic agent: 0.5 parts. Under normal temperature conditions, add the formula amount of polyurethane resin slurry and dissolving agent into a clean stainless steel bucket, turn on the high-speed mixer, and fully stir the material in the stainless steel bucket at a speed of 400rpm for 5 minutes, and then add the formula amount of curing agent in sequence , antistatic agent, delayed catalyst, mix evenly according to the above formula amount and adding order, each time a substance is added, mix at 400rpm for 5 minutes to ensure the accuracy of the formula and the uniformity of mixing.

[0...

Embodiment 2

[0040] S1, the preparation of polyurethane pressure-sensitive adhesive: According to the mass ratio, polyurethane resin slurry PU-1 (viscosity 12000, weight average molecular weight 90000, solid content 66%), 100 parts, EA: 250 parts, TDI: 7 parts, triethylene Diamine-o-dicyano-sodium diacetate (TEDA-DCN-Ac) delayed catalyst: 0.023 parts; 2-(11-methyldodecyloxy) ethanol phosphate antistatic agent: 0.7 parts. Under normal temperature conditions, add the formula amount of polyurethane resin slurry and dissolving agent into a clean stainless steel bucket, turn on the high-speed mixer, and fully stir the material in the stainless steel bucket at a speed of 300rpm for 8 minutes, and then add the formula amount of curing agent in sequence , antistatic agent, delayed catalyst, mix evenly according to the above formula amount and adding order, each time a substance is added, mix at 300rpm for 8 minutes to ensure the accuracy of the formula and the uniformity of mixing.

[0041] S2, pr...

Embodiment 3

[0043] S1, the preparation of polyurethane pressure-sensitive adhesive: According to the mass ratio, polyurethane resin slurry PU-2 (viscosity 5000, weight average molecular weight 80000, solid content 70%), 100 parts, EA: 90 parts, TDI: 10 parts, triethylene Diamine-o-dicyano-sodium dinitrate (TEDA-DCN-NIT) delayed catalyst: 0.05; tributylmethylammonium bis(trifluoromethanesulfonyl)imide antistatic agent: 0.7 parts. Under normal temperature conditions, add the formula amount of polyurethane resin slurry and dissolving agent into a clean stainless steel bucket, turn on the high-speed mixer, and fully stir the material in the stainless steel bucket at a speed of 200rpm for 10 minutes, and then add the formula amount of curing agent in sequence , antistatic agent, delayed catalyst, mix evenly according to the above formula amount and adding order, and mix at 200rpm for 10 minutes for each substance added to ensure the accuracy of the formula and the uniformity of mixing.

[0044...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com