Method for producing high-temperature superconducting strip by multi-source ion injection source ex-situ deposition

A technology of high-temperature superconducting strips and spray sources, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., which can solve the problem of inability to accurately control the composition of the film, difficulty in controlling the uniformity of the coating, and process equipment. High cost and other issues, to achieve the effect of improving coating efficiency, improving production efficiency, and fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

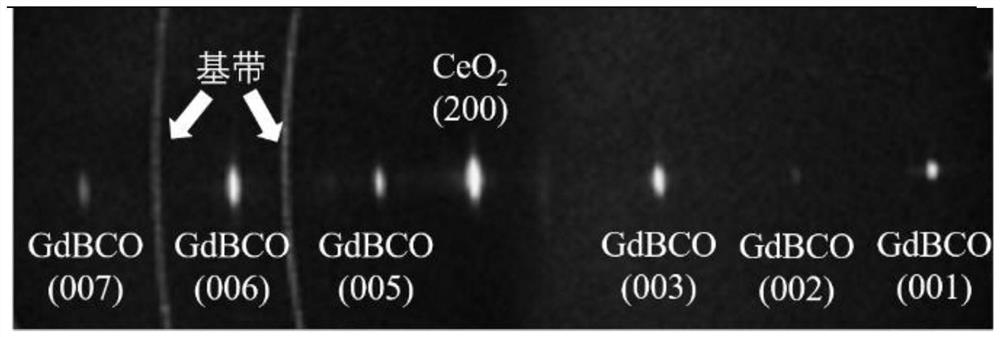

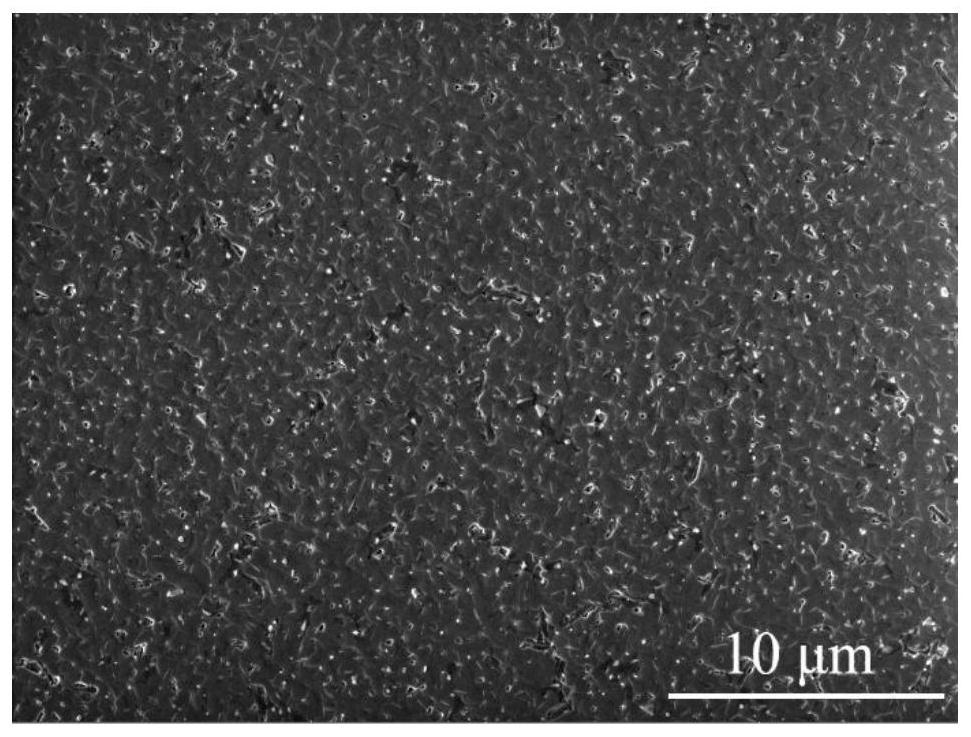

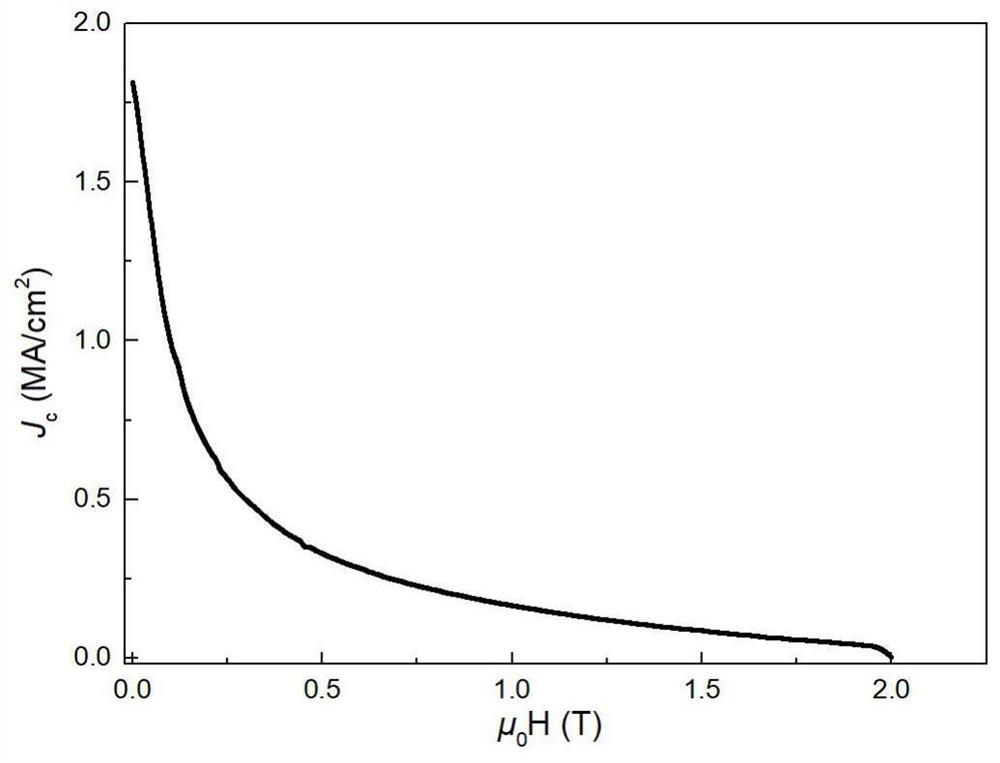

[0033]A method for producing high-temperature superconducting strips by ex-situ deposition of multi-source ion injection sources, taking the preparation process of GdBCO second-generation high-temperature superconducting strips as an example, includes the following steps:

[0034] A. In the deposition chamber, the buffer layer strip with biaxial texture passes near the target. The number of ion guns in the multi-source ion injection is 6, and the target is bombarded by 6 ion injection sources to form a plasma. Plume, so that a mixture of metal oxides is deposited on the buffer strip to form a precursor film;

[0035] Wherein, the buffer layer strip is a nickel-based or copper-based alloy, and the present embodiment selects a nickel-based alloy; the surface of the buffer layer strip is plated with CeO 2 / LaMnO 3 / MgO / Y 2 o 3 ; The target is Gd 2 o 3 , Ba 2 CO 3 , a homogeneously mixed target of three metal oxides of CuO, in which the atomic ratio of Gd, Ba, and Cu is 1:2...

Embodiment 2

[0039] A method for producing high-temperature superconducting strips by ex-situ deposition of multi-source ion injection sources, taking the preparation process of YGdBCO second-generation high-temperature superconducting strips as an example, includes the following steps:

[0040] A. In the deposition chamber, the buffer layer strip with biaxial texture passes near the target. The number of ion guns in the multi-source ion injection is 6, and the target is bombarded by 6 ion injection sources to form a plasma. Plume, so that a mixture of metal oxides is deposited on the buffer strip to form a precursor film;

[0041] Wherein the buffer layer strip is nickel-based or copper-based alloy, the present embodiment selects copper-based alloy; the surface of the buffer layer strip is plated with CeO 2 / LaMnO 3 / MgO / Y 2 o 3 ; target is Y 2 o 3 , Gd 2 o 3 , Ba 2 CO 3 A homogeneous mixture target composed of four metal oxides of CuO and CuO, wherein the atomic ratio of Y, Gd, ...

Embodiment 3

[0046] A method for producing high-temperature superconducting tapes by ex-situ deposition of a multi-source ion injection source to contain BaZrO 3 The preparation process of doped GdBaCuO second-generation high-temperature superconducting tape is taken as an example, including the following steps:

[0047] A. In the deposition chamber, the buffer layer strip with biaxial texture passes near the target. The number of ion guns in the multi-source ion injection is 8, and the target is bombarded by 8 ion injection sources to form a plasma. Plume, so that a mixture of metal oxides is deposited on the buffer strip to form a precursor film;

[0048] Wherein, the buffer layer strip is a nickel-based or copper-based alloy, and the present embodiment selects a copper-based alloy; the surface of the buffer layer strip is plated with CeO 2 / LaMnO 3 / MgO / Y 2 o 3 ; The target is Gd 2 o 3 , Ba 2 CO 3 , CuO and BaZrO 3 A homogeneously mixed target composed of four metal oxides. Am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com