Organosilicon crosslinked polymer and preparation method and application thereof

A cross-linked polymer and silicone technology, applied in the field of compounds, can solve the problems of phase separation and poor stability, and achieve the effects of improving compatibility and lubricity, improving toughness, and improving skin feel and lubricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing an organosilicon crosslinked polymer, comprising the following steps:

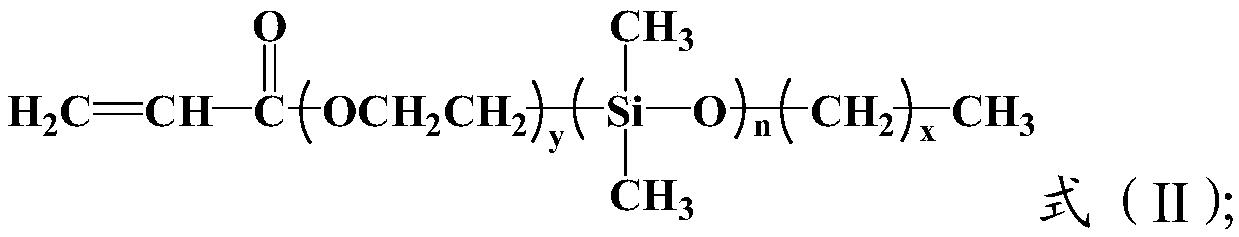

[0036] a) Mix long-chain alkyl polydimethylsiloxane polyethylene glycol with acrylic compound, and carry out esterification reaction under the first catalyst to obtain long-chain alkyl polydimethylsiloxane with the structure shown in formula (II) Silicone Polyethylene Glycol Acrylate;

[0037]

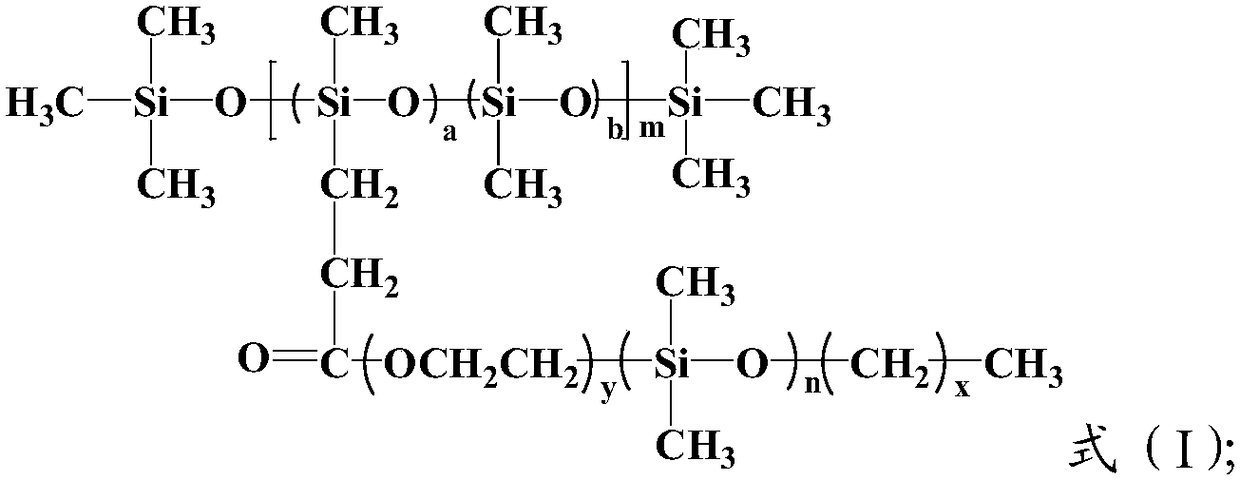

[0038] b) dissolving the long-chain alkyl polydimethylsiloxane polyethylene glycol acrylate in an organic solvent, adding polymethylhydrogensiloxane, and carrying out the addition and crosslinking reaction catalyzed by the second catalyst under anaerobic conditions, Obtain the organosilicon cross-linked polymer having the structure shown in formula (I);

[0039]

[0040] Wherein, x is 7-30, y is 1-100, n is 1-50, m is 1-100, a is 0-20, and b is 0-20.

[0041] In the present invention, the temperature of the esterification reaction is 80°C to ...

Embodiment 1

[0090] 1) 2g of acrylic acid is mixed with 20g of long-chain alkyl polydimethylsiloxane polyethylene glycol, stirred, after adding 0.03g of inhibitor hydroquinone and 0.22g of the first catalyst p-toluenesulfonic acid, at 90 Perform esterification reaction at ℃ for 6h to obtain long-chain alkyl polydimethylsiloxane polyethylene glycol acrylate;

[0091] 2) After dissolving 10 g of the long-chain alkyl polydimethylsiloxane polyethylene glycol acrylate prepared in step 1) in 35 ml of isopropanol, add to 15 g of polymethylhydrogen with an active hydrogen content of 0.18 wt % In siloxane, feed nitrogen and stir, then add 48 mg of 0.74% chloroplatinic acid isopropanol solution, raise the temperature to 80 ° C, carry out the addition and crosslinking reaction for 8 hours in the presence of the second catalyst chloroplatinic acid, and use rotary evaporation Remove the solvent isopropanol to obtain a silicone crosslinked polymer.

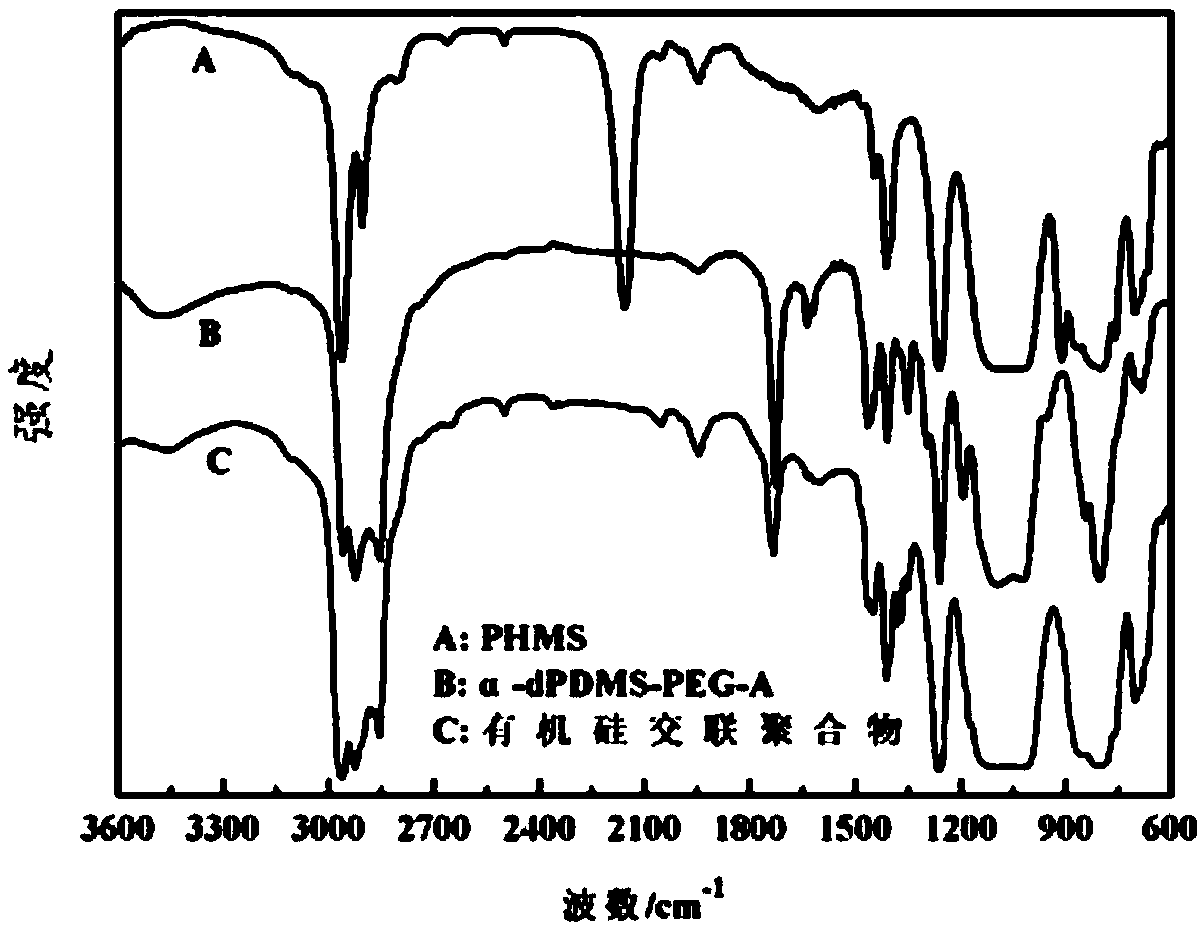

[0092] see figure 1 , is the infrared spectrogram o...

Embodiment 2

[0095] 1) 2g of acrylic acid is mixed with 16g of long-chain alkyl polydimethylsiloxane polyethylene glycol, stirred, after adding 0.03g of inhibitor hydroquinone and 0.18g of the first catalyst p-toluenesulfonic acid, at 100 Perform esterification reaction at ℃ for 8h to obtain long-chain alkyl polydimethylsiloxane polyethylene glycol acrylate;

[0096] 2) After dissolving 10 g of the long-chain alkyl polydimethylsiloxane polyethylene glycol acrylate prepared in step 1) in 35 ml of isopropanol, add to 15 g of polymethylhydrogen with an active hydrogen content of 0.18 wt % In siloxane, feed nitrogen and stir, then add 48 mg of 0.74% chloroplatinic acid isopropanol solution, raise the temperature to 80 ° C, carry out the addition and crosslinking reaction for 8 hours in the presence of the second catalyst chloroplatinic acid, and use rotary evaporation Remove the solvent isopropanol to obtain a silicone crosslinked polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com