High-toughness and flame-retardant PC/PBT alloy material and preparation method

An alloy material and high toughness technology, applied in the field of high toughness flame retardant PC/PBT alloy materials and preparation, can solve the problems of unsatisfactory flame retardant properties of alloy materials, limit the application range of alloy materials, and cannot prevent burning, etc. Excellent halogen-free smoke suppression and flame retardant properties, low cost of raw materials, good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

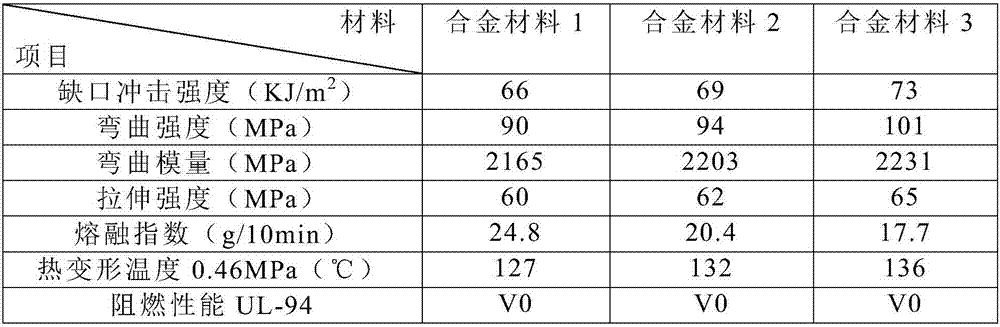

Embodiment 1

[0028] The present embodiment provides a PC / PBT alloy material component. Specifically, the PC / PBT alloy material component includes 80 parts by mass of PC, 20 parts of PBT, 15 parts of toughening agent and 3 parts by mass. of flame retardants.

[0029] The toughening agent is ACR, and the flame retardant is a mixture of nano-magnesium hydroxide, nano-montmorillonite and organic silicon flame retardant with a mass ratio of 1:1:1.

[0030] The mass fraction ratio of PC and PBT contained in the PC / PBT alloy material has a great influence on the properties of the alloy material. With the increase of PC content, the tensile strength, flexural strength and heat deflection temperature of the alloy material increase, and the solvent resistance decreases. This is because the toughness, tensile modulus and heat deflection temperature of PC are higher than PBT, solvent resistance is lower than PBT. The notched impact strength of alloy materials increases first and then decreases with ...

Embodiment 2

[0038] The present embodiment provides a PC / PBT alloy material component. Specifically, the PC / PBT alloy material component includes 90 parts by mass of PC, 10 parts of PBT, 10 parts of toughening agent and 5 parts by mass. of flame retardants.

[0039] The toughening agent is MBS, and the flame retardant is a mixture obtained by uniformly mixing nano-magnesium hydroxide and nano-montmorillonite at a mass ratio of 1:1.

[0040] MBS is a typical particle-dispersed toughening modifier. It is a functional polymer material synthesized on the basis of the concept of particle design. It is a ternary polymer prepared by emulsion graft polymerization. It has a typical core-shell in submicroscopic form. Structure, the core of the particle is lightly cross-linked styrene-butadiene rubber core with low shear modulus, and the outer shell is a hard shell layer formed by grafting styrene and methyl methacrylate. The principle of toughening and modifying PC / PBT alloy materials is exactly th...

Embodiment 3

[0042] The present embodiment provides a PC / PBT alloy material component. Specifically, the PC / PBT alloy material component includes 70 parts by mass of PC, 30 parts of PBT, 20 parts of toughening agent and 1 part of flame retardants.

[0043] The toughening agent is ACR and MBS with a mass ratio of 1:1, and the flame retardant is nano-magnesium hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com