An Additive Machining Forming Method for Complex Parts and Molds

A technology for complex parts, processing and forming, applied in the direction of additive processing, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome process, and achieve the effect of wide applicability, good toughness and improved process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

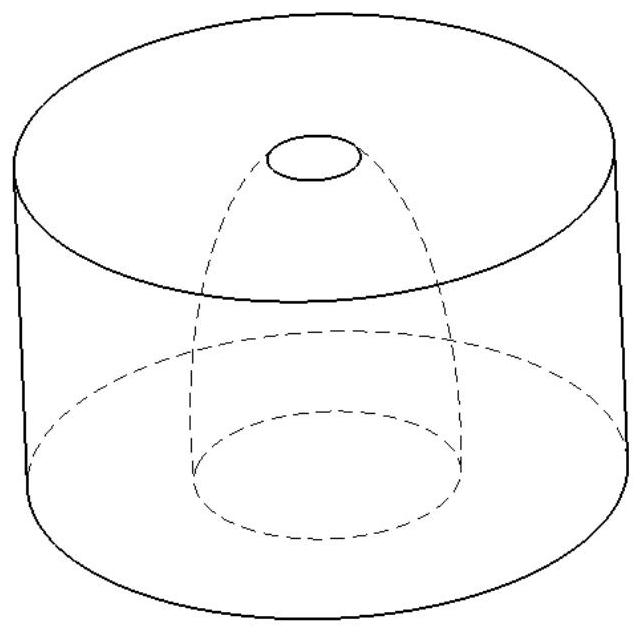

[0047] In this embodiment, the method of the present invention is further described by taking a metal part with a complex shape in the middle and two ends not closed as an example, which includes the following steps:

[0048] (1) Referring to Figure 1(a), the CAD geometric model of the part is established according to the three-dimensional shape and size of the target part, the STL model of the part is extracted, and the layer thickness is selected according to the actual shape and size of the part. In the actual operation process, the The layer thickness can be selected according to the actual needs. According to the shape and complexity of the part, the layer thickness of each layer can be the same or different, and the material can be the same or different. It is determined by the processing technology requirements of the part, and the operator can do it as needed. Reasonable selection and division, in the present embodiment, the layered thickness of each layer is selected t...

Embodiment 2

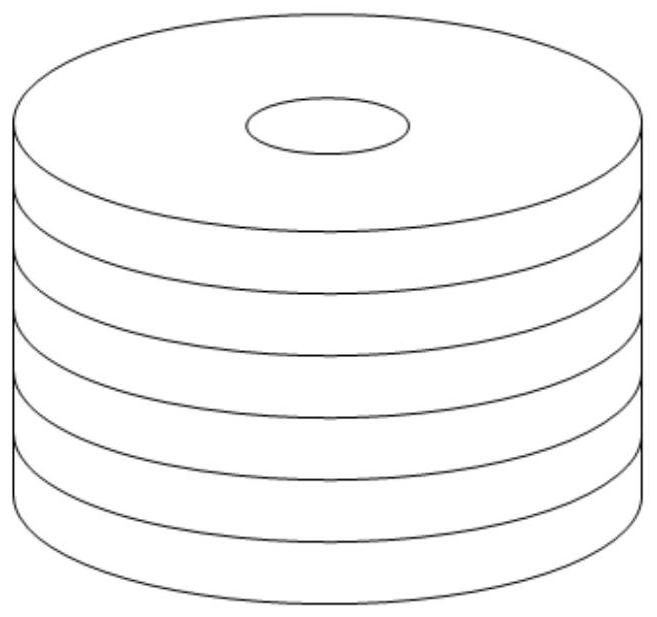

[0055] In this embodiment, the method of the present invention is further described by taking a metal mold with a complex shape and closed ends in the middle as an example, which includes the following steps:

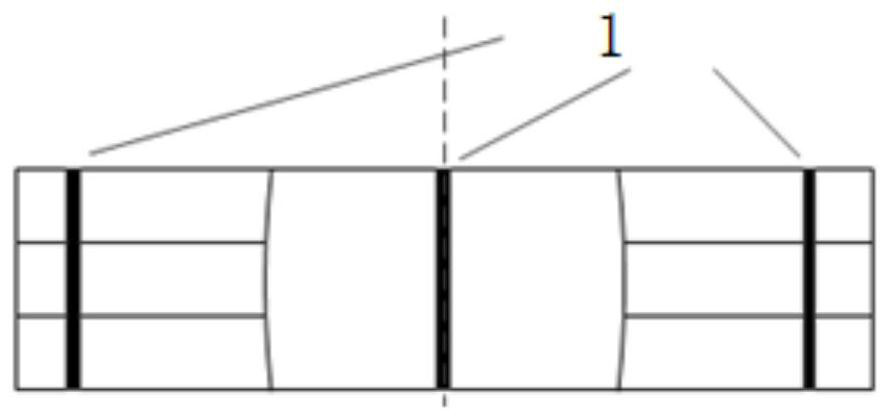

[0056] (1) Referring to Figure 2(a)-(b), the mold CAD geometric model is established according to the three-dimensional shape and size of the target mold, the STL model of the mold is extracted, and the layered thickness is selected according to the actual forming shape and size of the mold. During the process, the layer thickness can be selected according to the actual needs. According to the shape and complexity of the mold, the layer thickness of each layer can be the same or different, and the material can be the same or different, which is determined by the processing technology requirements of the mold. The operator Reasonable selection and division can be carried out according to needs, as shown in Figure 2 (c), the present embodiment is divided into blocks and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com