Application of 3D printing in cross-linked polyimide, preparation of porous polyimide, preparation of polyimide composites

A 3D printing, polyimide technology, applied in applications, additive processing, household appliances, etc., can solve the problem of high heat-resistant cross-linked polyimide 3D printing and less research, thermosetting polyimide It can solve the problems of reduced thermal properties of parts, difficult-to-melt and high-temperature-resistant cross-linked polyimide, etc., to achieve the effect of abundant pores, excellent dimensional stability, and enhanced van der Waals force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a direct-writing 3D printing cross-linked porous polyimide, comprising the following steps:

[0037] Mixing polyamic acid, organic solvent and porogen to obtain polyamic acid ink;

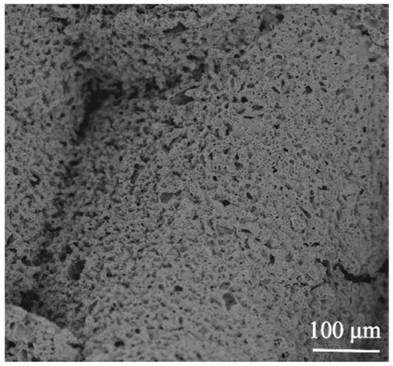

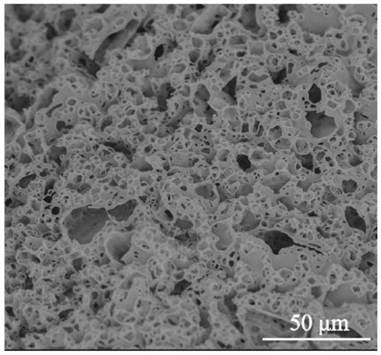

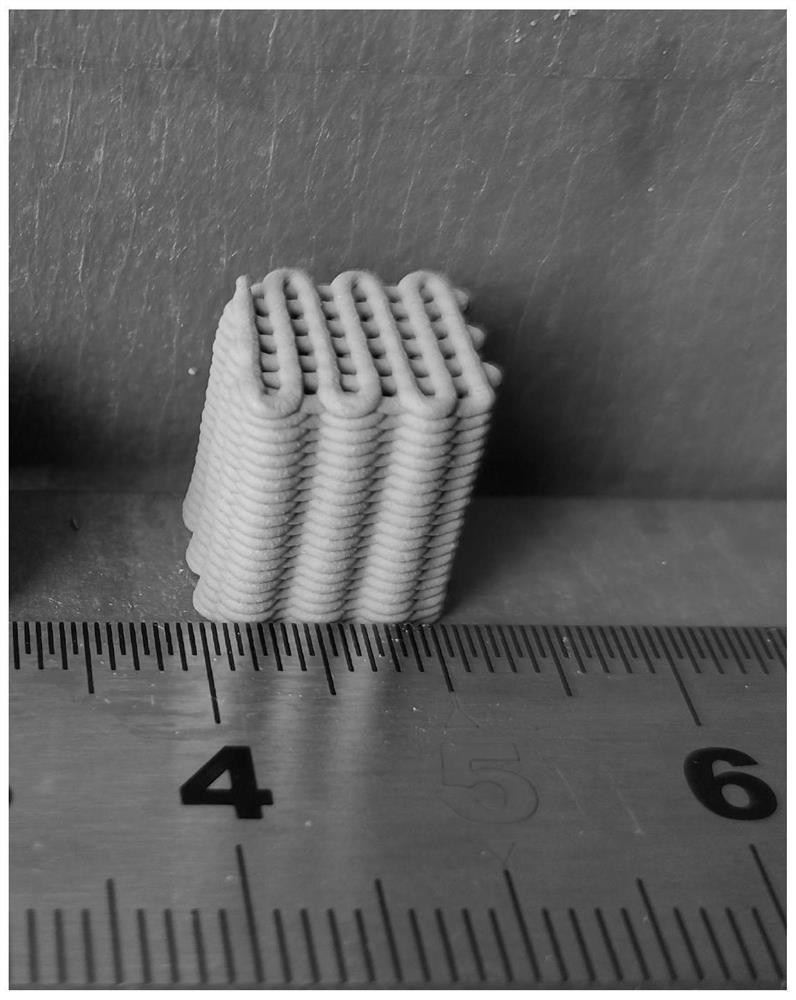

[0038] performing direct writing 3D printing on the polyamic acid ink to obtain a 3D printed component;

[0039] The 3D printed component is heat-treated to obtain a cross-linked porous polyimide.

[0040] In the present invention, unless otherwise specified, the required preparation raw materials are all commercially available products well known to those skilled in the art.

[0041] In the present invention, the polyamic acid, the organic solvent and the porogen are mixed to obtain the polyamic acid ink. In the present invention, the number average molecular weight of the polyamic acid corresponding to the polyimide is preferably 5000-50000 g / mol, more preferably 10000-30000 g / mol; the polyamic acid is preferably:

[0042]

[0043] The pres...

Embodiment 1

[0078] (1) Preparation of polyamic acid powder: under nitrogen atmosphere, 4.9199g of 4,4'-diaminodiphenyl ether was dissolved in 70mL of N,N-dimethylformamide, and 10.4707g was added in three batches under ice bath conditions. g 4,4'-(hexafluoroisopropene)diphthalic anhydride, remove the ice bath after 1 hour of reaction, after 5 hours of reaction at room temperature, add 0.4965g of 4-phenylethynyl phthalic anhydride and add 20 mL of N,N-dimethylformamide , continue to react for 24h to obtain a polyamic acid solution with a solid content of 15%, pour the polyamic acid solution into a mixed solution of water and ethanol (volume ratio is 4:1) under excessive stirring conditions, and then put the obtained white The solid was soaked in the above mixed solution of water and ethanol for 12h, filtered and washed with water, dried at 80°C for 12h, the obtained solid was pulverized by a pulverizer, and sieved with a 100-mesh sieve to obtain polyamic acid powder, corresponding to the nu...

Embodiment 2

[0084] 6 parts of the polyamic acid powder prepared in Example 1, 4 parts of N,N-dimethylformamide and 15 parts of sodium chloride with a particle size of less than 300 meshes were ball-milled at room temperature, and the ball-milling time was 30min and the ball-milling rate was 3000r / min, the obtained mixture is pumped and centrifuged to remove air bubbles to obtain polyamic acid ink;

[0085] Direct writing 3D printing and heat treatment were carried out by the same method as in Example 1. After immersion in deionized water for 12 h, the obtained part was taken out, washed with deionized water, and dried to obtain a cross-linked porous polyimide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com