Pretreatment method for improving activity of NH3-SCR catalyst

A technology of NH3-SCR and catalyst, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. It can solve problems such as safety and equipment corrosion, and achieve great application potential , With the effects of NO conversion rate and N2 selectivity, high NO conversion rate and N2 selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Accurately measure 0.01mol Ce(NO 3 ) 3 ·6H 2 O and 0.01mol Fe 2 (NO 3 ) 3 9H 2 O, respectively dissolved in 50mL distilled water and magnetically stirred at room temperature for 0.5h, then dropwise added 25%wt ammonia water to the solution to ensure that the pH of the solution was greater than or equal to 10.0, then magnetically stirred at room temperature for 3h to make the precipitation complete, Aged for 3 hours, filtered, washed with deionized water for 3 times, dried in an oven at 100°C for 12 hours, ground evenly, and then calcined at 400°C for 4 hours in an air atmosphere in a muffle furnace to obtain FeCeO x powder. Take 0.01 mol of roasted powder sample, 0.01 mol of citric acid and 0.005 mol of oxalic acid, dissolve in 50 mL of distilled water and stir magnetically at room temperature for 3 hours, dry at 120°C oil bath for 6 hours, and dry in an oven at 120°C 12h, grind evenly, and then bake at 400°C for 4h in an air atmosphere in a muffle furnace. The ...

Embodiment 2

[0027] Apply the iron-cerium composite oxide catalyst prepared in Example 1 to NH 3 -SCR reaction, the specific reaction conditions are as follows: The catalytic reaction test is carried out in a fixed-bed continuous flow quartz reactor. The particle size of the catalyst is 40-60 mesh, and the dosage is 200 mg. The reaction gas composition is: 500ppm NO, 500ppm NH 3 ,5%O 2 ,N 2 As a balance gas, the gas space velocity in the reaction is 60,000 mL·mg –1 h –1 . Before the reaction, the catalyst needs to use high-purity N 2 Purge at 200°C for 20 minutes. Catalytic reactions were carried out at 100-400°C, and activity data were collected after the reaction reached equilibrium. The product was detected and analyzed by Thermofisher IS10 FTIR, NO conversion rate and N 2 Selectivity is calculated by the following formula:

[0028]

[0029]

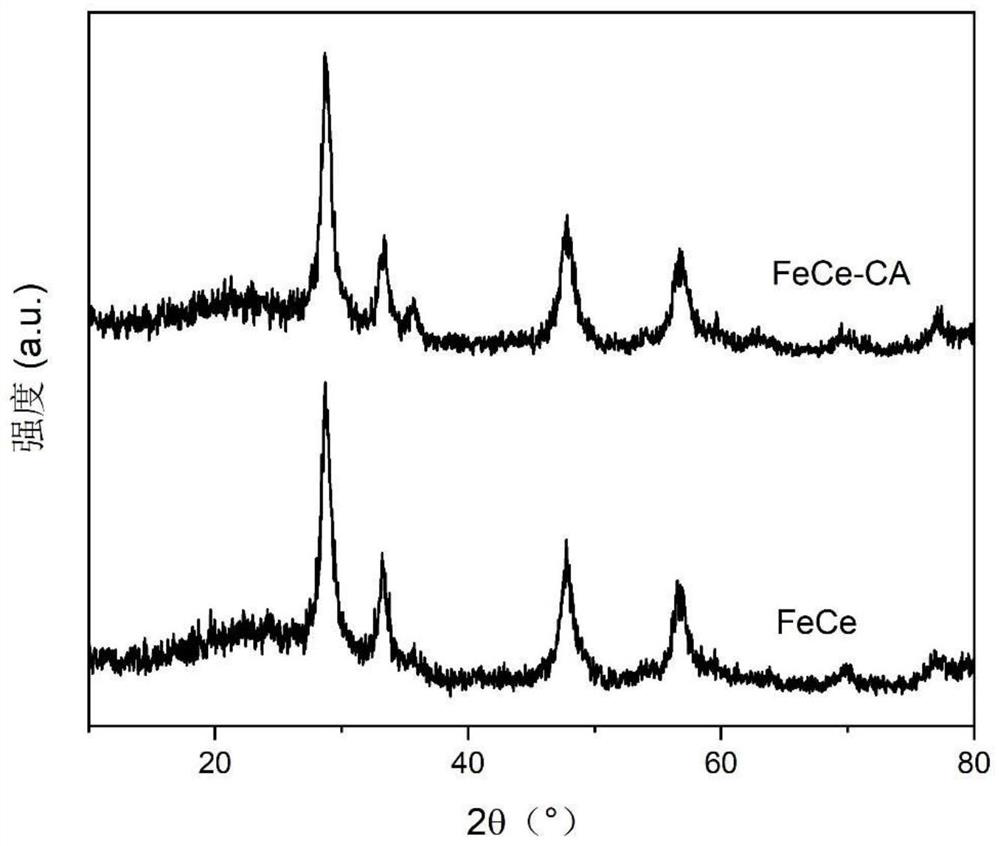

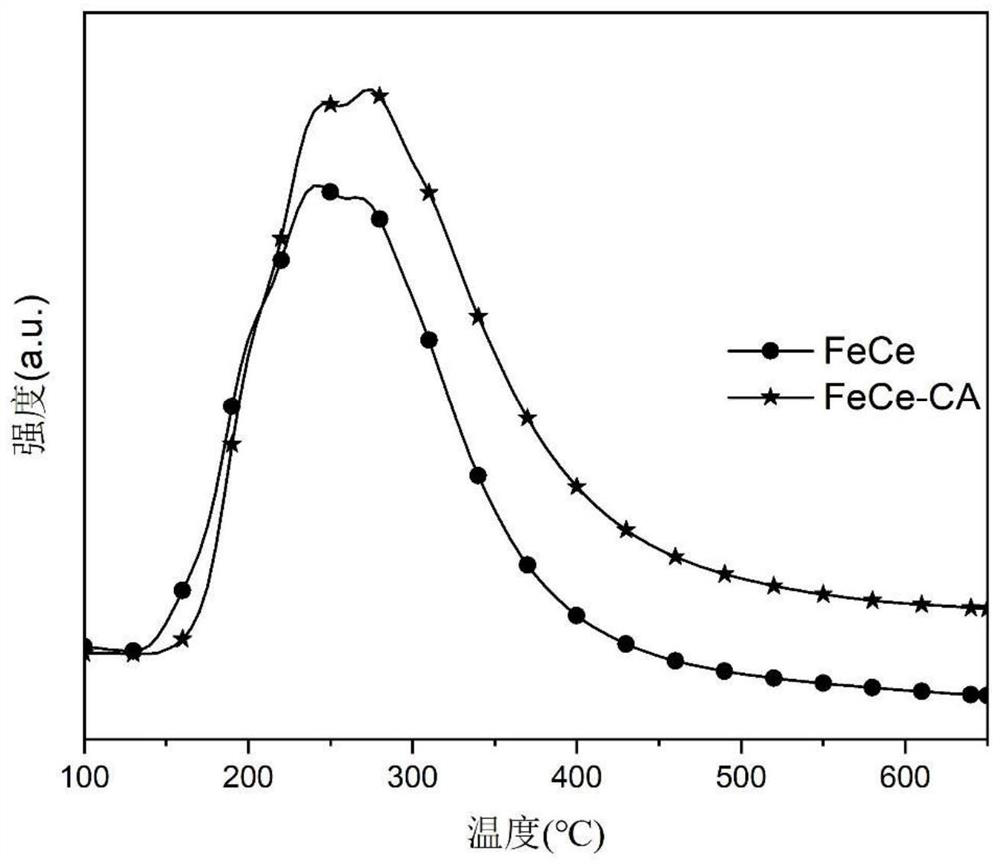

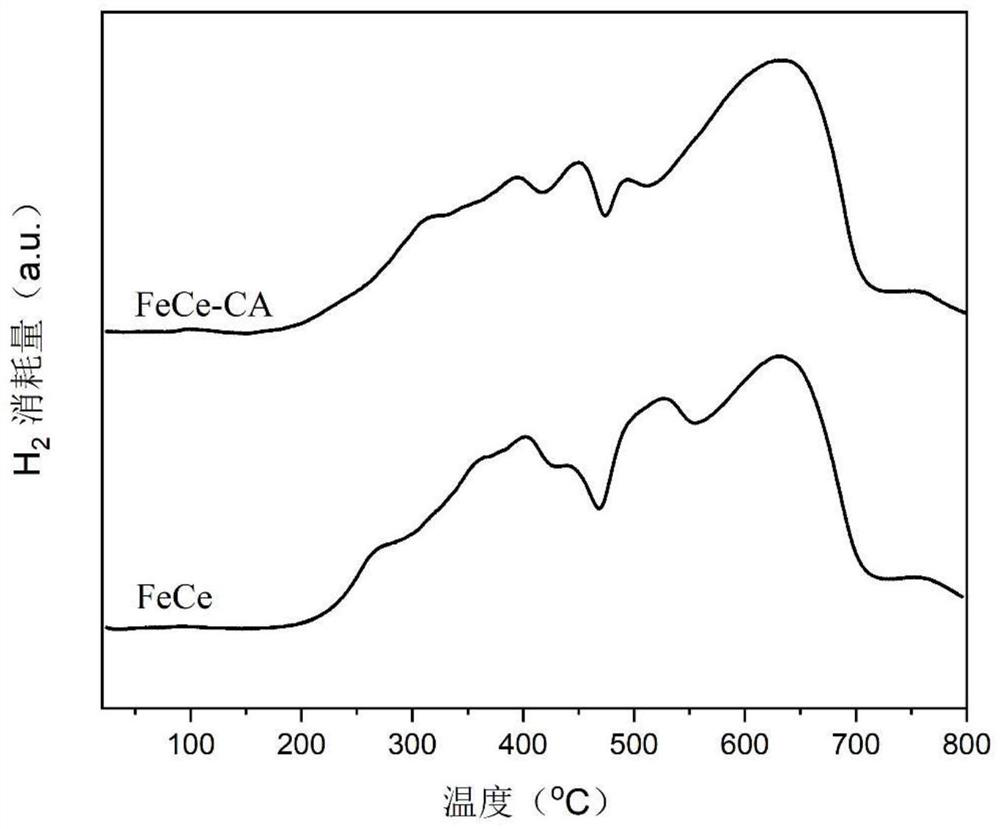

[0030] The iron-cerium composite oxide catalyst prepared by the present invention passes through X-ray diffraction (XRD), ammonia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com