Titanium dioxide photocatalytic material as well as preparation method and application thereof

A photocatalytic material, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, chemical instruments and methods, etc., can solve the problems of confinement, rapid recombination of electron-hole pairs, light absorption limitation, etc., to reduce the recombination rate , rich surface defects, convenient and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of preparation method of titanium dioxide photocatalytic material of the present invention, comprises the steps:

[0030] Step 1: TiCl 3 As a titanium source, disperse in the solvent, stir at room temperature to dissolve, and the stirring time is 0.5-1h. This step uses dilute hydrochloric acid solution of titanium trichloride, TiCl 3 The added amount is 1.435-5.74mL, the solvent is absolute ethanol, and the volume is 30-40mL;

[0031] The relevant description of titanium trichloride dilute hydrochloric acid solution is as follows figure 1 shown;

[0032] Step 2: transfer the solution obtained in the first step into the inner lining of the reaction kettle, put it into an oven for reaction, and raise the temperature to 180-220°C for 5-24 hours;

[0033] Step 3: Cool naturally to room temperature after the reaction, collect the obtained product for centrifugation, wash with ethanol, and dry at 60-70°C for 3-5 hours to obtain white powder TiO 2 .

[0034] The wh...

Embodiment 1

[0037] A kind of preparation method of titanium dioxide photocatalytic material of the present invention, comprises the steps:

[0038] Weigh 2.87mLTiCl 3 Dissolve in 30mL of absolute ethanol, stir at room temperature for 30 minutes to completely dissolve, and transfer the obtained solution into the lining of the reaction kettle.

[0039] Put it into an oven and raise the temperature to 220° C., keep it warm for 6 hours, and then cool it down to room temperature naturally. The resulting reactants were collected, washed with absolute ethanol and centrifuged and dried at 60°C for 3 hours to obtain white TiO 2 Powder.

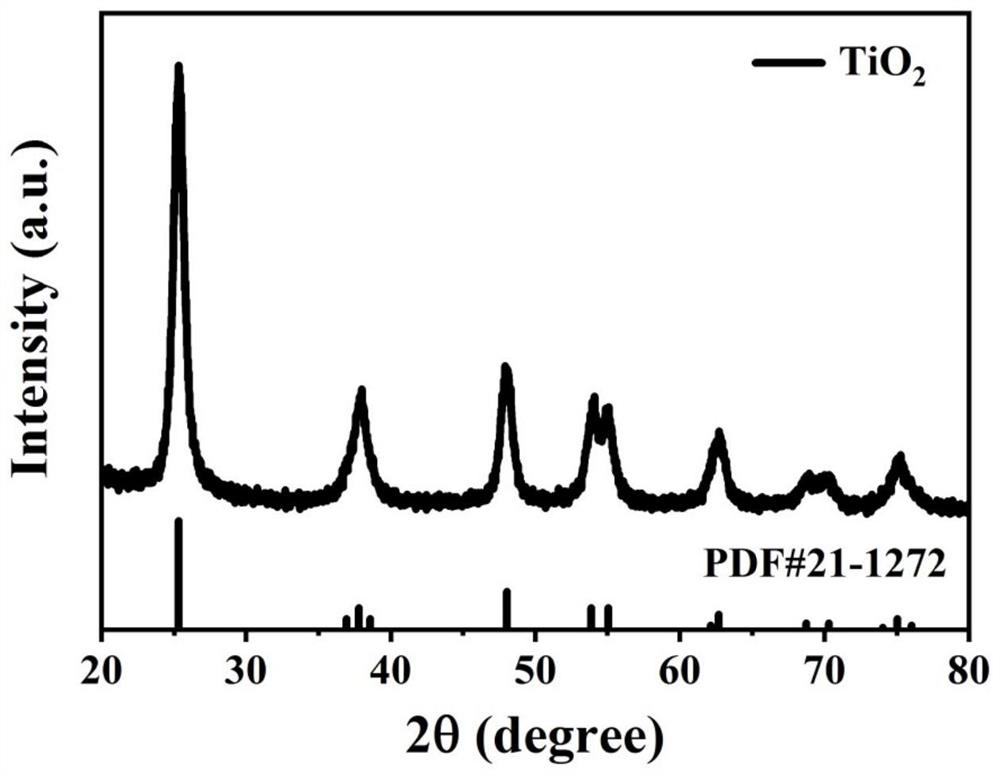

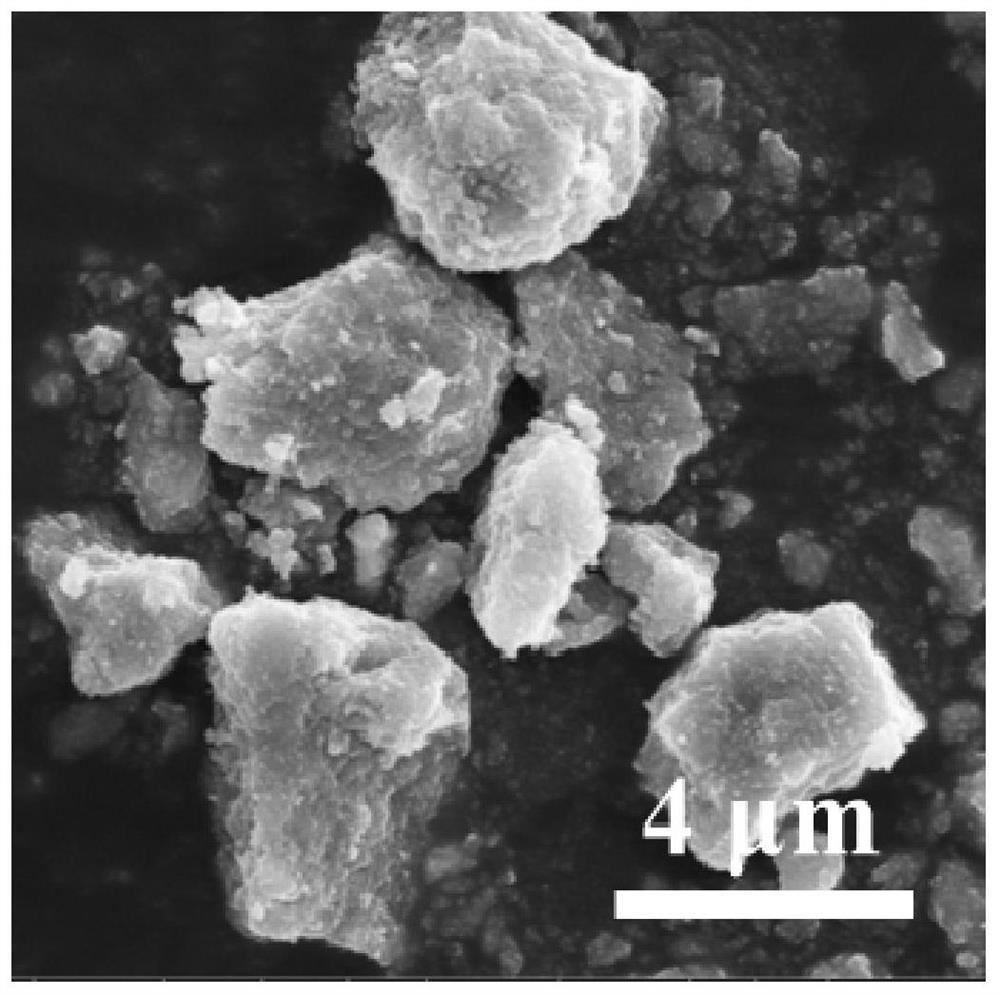

[0040] figure 2 is TiO 2 The X-ray diffraction spectrum (XRD) of powder, all diffraction peaks all and TiO 2 The standard card (PDF#21-1272) is completely consistent without any miscellaneous peaks, indicating that the synthesized TiO 2 The powder is a pure phase. Synthetic TiO 2 The XRD diffraction peaks of the powder show that the sample has a high degr...

Embodiment 2

[0045] A kind of preparation method of titanium dioxide photocatalytic material of the present invention, comprises the steps:

[0046] Weigh 1.435mL TiCl3 Dissolve in 30mL of absolute ethanol, stir at room temperature for 30 minutes to completely dissolve, and transfer the obtained solution into the lining of the reaction kettle.

[0047] Put it into an oven and raise the temperature to 220° C., keep it warm for 6 hours, and then cool it down to room temperature naturally. The resulting reactants were collected, washed with absolute ethanol and centrifuged, then dried at 60°C for 3 hours to obtain white TiO 2 Powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com