Catalyst for preparing CO by reverse water gas shift method and preparation method thereof

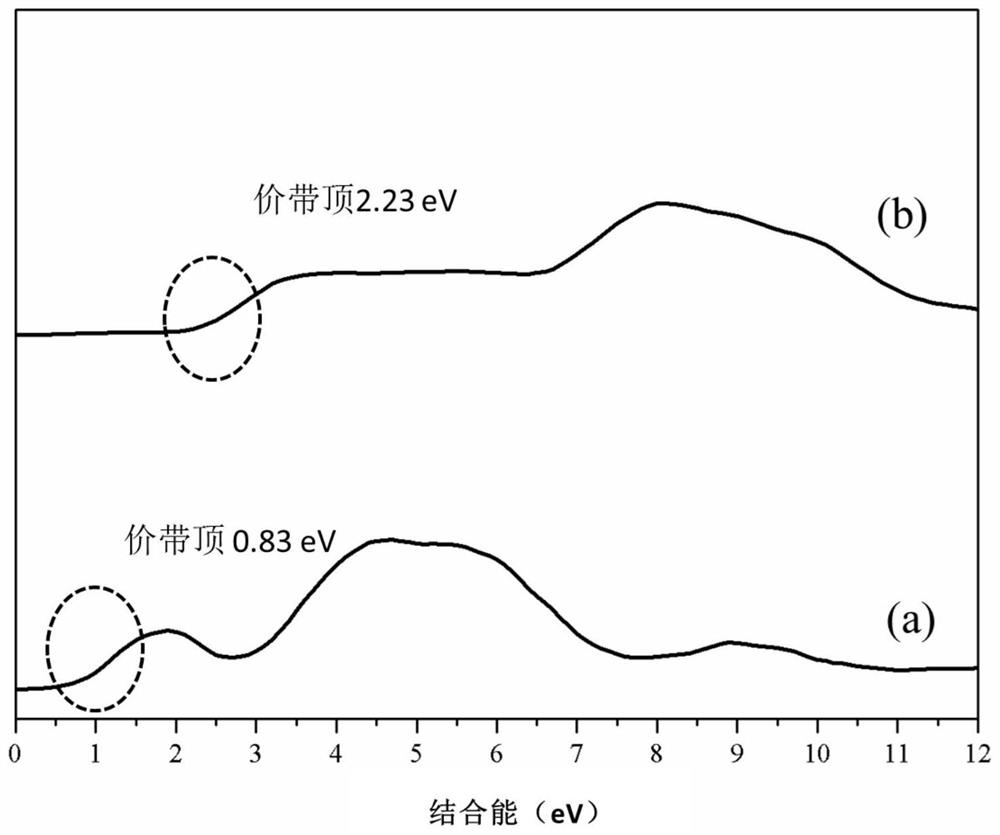

A water-gas shift, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, carbon monoxide, etc., can solve the problems of weakening atom economy, harsh synthetic route conditions, high cost, etc., to enrich surface defects, improve Effects of valence band energy levels and electron transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A. Weigh 0.36g of palladium chloride and dissolve it in 50ml of deionized water to prepare an active component solution with a concentration of 0.04mol / L; weigh 10g of cerium oxide powder and immerse it in the solution and age it at 25°C for 24h; The final powder was dried in an oven at 120° C. for 10 hours, and then placed in a muffle furnace and calcined at 450-500° C. for 20 hours to obtain catalyst precursor 1 with a palladium mass percentage of 2 wt.%.

[0028] B. Weigh 1.6g of anhydrous cerium chloride and mix it with the catalyst precursor 1 obtained in step A, and then perform mechanical grinding. The molar ratio of anhydrous cerium chloride to cerium oxide in the precursor 1 is 1:3.

[0029] C. Put the mixed powder in a He atmosphere and raise the temperature to 300°C and heat treatment at constant temperature for 3h; then raise the temperature to 500°C at a rate of 2°C / min, and switch the atmosphere to H 2 atmosphere and heat treatment at constant temperature ...

Embodiment 2

[0033] Steps A~C are the same as in Example 1;

[0034] The mass of ammonium iodide added in step D is 33.7g, and the molar ratio of ammonium iodide to the cerium element in the catalyst precursor 2 is 3:1;

[0035] O in step E 2 / N 2 O in the atmosphere 2 The concentration is 20%.

[0036] The I / Pd molar concentration ratio on the catalyst surface was measured to be 0.31. The application performance results are shown in Table 1.

Embodiment 3

[0038] Steps A~D are the same as in Example 1,

[0039] The oxidation-reduction process described in step E is carried out 3 times in a cycle.

[0040] The I / Pd molar concentration ratio on the catalyst surface was measured to be 0.37. The application performance results are shown in Table 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com