A kind of converter large surface repair material and preparation method thereof

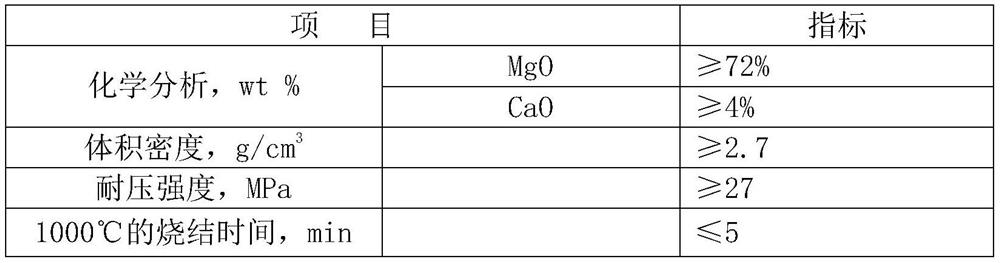

A technology for repairing materials and large surfaces, applied in the field of refractory materials, can solve the problems of long sintering time, general durability, and complicated production, and achieve the effects of short sintering time, improved high-temperature flexural strength, and good high-temperature mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

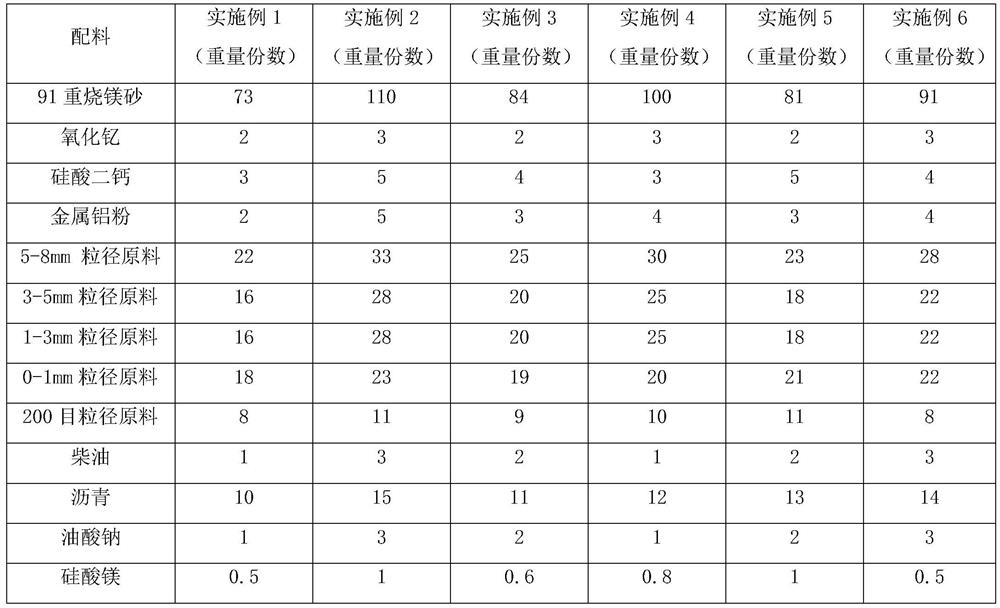

[0025] Embodiments of the present invention are further described below:

[0026] A converter large surface repair material is prepared from the following raw materials in parts by weight:

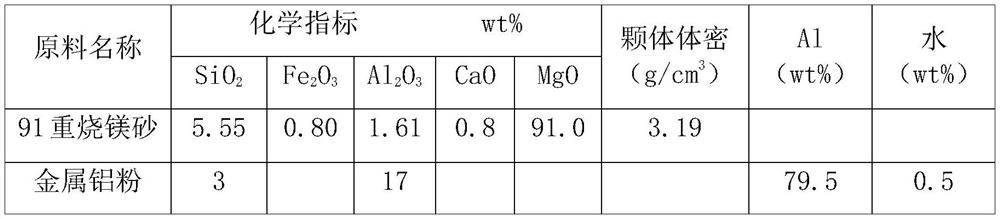

[0027] Aggregate: 73-110 parts of dead burnt magnesia;

[0028] Ingredients: 2-5 parts of metal aluminum powder with a particle size of 200 meshes, 2-3 parts of yttrium oxide, and 3-5 parts of dicalcium silicate;

[0029] Binder: 10-15 parts of asphalt, 1-3 parts of sodium oleate, 0.5-1 part of magnesium silicate;

[0030] Additives: 1-3 parts of diesel.

[0031] A preparation method of a converter large surface repair material, the specific method is as follows:

[0032] 1) Crushing the dead-burned magnesia in the above parts by weight in a crusher to make raw materials with a particle size of 200 mesh;

[0033] 2) Premixing the prepared dead-burned magnesia with a particle size of 200 mesh and the above-mentioned parts by weight of aluminum powder, dicalcium silicate and yttrium oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com