A kind of preparation method and application of porous carbon

A technology of porous carbon and carbon materials, applied in chemical instruments and methods, nano-carbon, other chemical processes, etc., can solve the problems of low processing efficiency, energy consumption, refractory degradation, etc., to improve the capture performance and superior capture effect. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Put salts containing a certain amount of water, boron, and biofunctional macromolecules (containing amino and carboxyl groups) in a steamer-shaped container and heat the water vapor to a certain temperature to cause it to lose its original spatial structure and denature;

[0034] Step 2: freeze-drying: the obtained precursor particles are freeze-dried to form a "honeycomb" structure material composed of nanosheets;

[0035] Step 3: Carry out the "honeycomb" structure substance composed of nanosheets obtained after the above-mentioned freeze-drying

[0036] Electron beam radiation heating modification, the electron beam radiation heating modification time is 70 minutes, and the functionalized porous nanosheet carbon material containing sulfur, boron, nitrogen elements and bulk phase defects is prepared, showing good organic chemical wastewater capture effect.

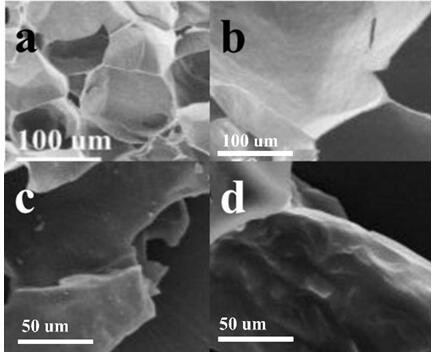

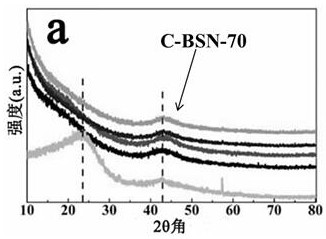

[0037] figure 1 It is the scanning electron micrograph (SEM) of C-BSN-70 prepared in Example 1. Afte...

Embodiment 2

[0040] Step 1: Put salts containing a certain amount of water, boron, and biofunctional macromolecules (containing amino and carboxyl groups) in a steamer-shaped container and heat the water vapor to a certain temperature to cause it to lose its original spatial structure and denature;

[0041] Step 2: freeze-drying: the obtained precursor particles are freeze-dried to form a "honeycomb" structure material composed of nanosheets;

[0042] Step 3: Carry out the "honeycomb" structure substance composed of nanosheets obtained after the above-mentioned freeze-drying

[0043] Electron beam radiation heating modification, the electron beam radiation heating modification time is 20 minutes, and the functionalized porous nanosheet carbon material containing sulfur, boron, nitrogen elements and bulk phase defects is prepared, showing good organic chemical wastewater capture effect.

Embodiment 3

[0045] Step 1: Put salts containing a certain amount of water, boron, and biofunctional macromolecules (containing amino and carboxyl groups) in a steamer-shaped container and heat the water vapor to a certain temperature to cause it to lose its original spatial structure and denature;

[0046] Step 2: freeze-drying: the obtained precursor particles are freeze-dried to form a "honeycomb" structure material composed of nanosheets;

[0047] Step 3: Carry out the "honeycomb" structure substance composed of nanosheets obtained after the above-mentioned freeze-drying

[0048] Electron beam radiation heating modification, the electron beam radiation heating modification time is 40 minutes, and the functionalized porous nanosheet carbon material containing sulfur, boron, nitrogen elements and bulk phase defects is prepared, showing good organic chemical wastewater capture effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com