Anti-corrosion and waterproof emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and emulsifier, which is applied in chemical instruments and methods, anti-corrosion coatings, asphalt coatings, etc. It can solve the problems that emulsified asphalt is difficult to achieve anti-corrosion, emulsified asphalt for waterproof coatings, narrow emulsification range, emulsifier migration, etc., to achieve Improve emulsification effect, excellent water resistance and anti-corrosion performance, excellent anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

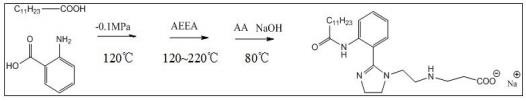

[0053] Under the protection of nitrogen atmosphere, add 220kg of lauric acid, 137kg of anthranilic acid, and tetrabutylammonium bromide (0.02wt% of the total reactants) into the reactor, heat up to 120°C and vacuumize for reaction , lower the temperature when the amine value=0mgKOH / g, wash with alkali, filter, and dry to obtain the intermediate;

[0054] Add the above-mentioned intermediate to the reaction kettle, fill with nitrogen and exhaust oxygen, add 115kg of diethylenetriamine and alumina (the amount added is 0.01wt% of the total reactants), and heat up the reaction in stages, 120°C for 1h, 130°C for 1h, 140°C 1h at ℃, 1h at 150°C, 1h at 160°C, 1h at 170°C, 1h at 180°C, 1h at 190°C, 1h at 200°C, 1h at 220°C acid value = 0mg KOH / g. Cool down to 80°C, add 300kg of water, slowly add 50kg of acrylic acid dropwise, react at constant temperature for 2 hours, add sodium hydroxide solution to adjust the pH value to 9.5, and discharge to obtain an emulsifier.

Embodiment 2

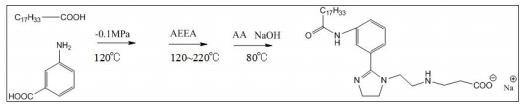

[0056] Under the protection of nitrogen atmosphere, 282kg of oleic acid, 137kg of m-aminobenzoic acid, and 2,4,6-tris(dimethylaminomethyl)phenol (the addition amount is 0.02wt% of the total reactant) were added to the reactor , heating up to 120°C and vacuumizing for reaction, cooling down when the amine value = 0mg KOH / g, washing with alkali, filtering and drying to obtain the intermediate;

[0057] Add the above intermediate to the reaction kettle, fill with nitrogen and exhaust oxygen, add 115kg of diethylenetriamine, boric acid (the amount added is 0.01wt% of the total reactants), and heat up the reaction in stages, 120°C for 1h, 130°C for 1h, and 140°C 1h, 150°C 1h, 160°C 1h, 170°C 1h, 180°C 1h, 190°C 1h, 200°C 1h, 220°C 1h. Acid value = 0 mg KOH / g After the reaction is over, vacuumize at 220°C to remove unreacted amines, cool down to 80°C, add 300kg of water, slowly add 50kg of acrylic acid dropwise, react at constant temperature for 2 hours, add sodium hydroxide solutio...

Embodiment 3

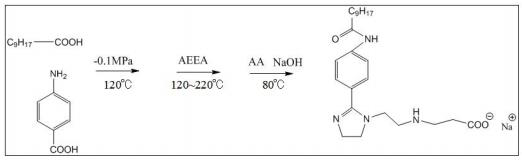

[0059] In the case of nitrogen atmosphere protection, 126kg of naphthenic acid, 137kg of p-aminobenzoic acid, and tetrabutylammonium bromide (the addition amount is 0.02wt% of the total reactants) are added to the reactor, and the temperature is raised to 120°C and vacuumized. Reaction, cooling down when the amine value = 0mgKOH / g, washing with alkali, filtering and drying to obtain the intermediate;

[0060] Add the above intermediate to the reaction kettle, fill with nitrogen and exhaust oxygen, add 115kg of diethylenetriamine and triphenylphosphine (the amount added is 0.01wt% of the total reactants), and heat up the reaction in stages, 120°C for 1h, 130°C for 1h , 140°C for 1h, 150°C for 1h, 160°C for 1h, 170°C for 1h, 180°C for 1h, 190°C for 1h, 200°C for 1h, 220°C for 1h Acid value = 0mg KOH / g. For amine, cool down to 80°C, add 300kg of water, slowly add 50kg of acrylic acid dropwise, react at constant temperature for 2 hours, add sodium hydroxide solution to adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com