Graphene oxide nanosheet modified azine ring structure temperature-resistant corrosion-resistant inert coating and preparation method thereof

A technology of graphene nanosheets and stone oxide, applied in coatings, epoxy resin coatings, anti-corrosion coatings, etc., to achieve the effects of improving toughness, anti-corrosion penetration and anti-γ-ray radiation performance, and reducing temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

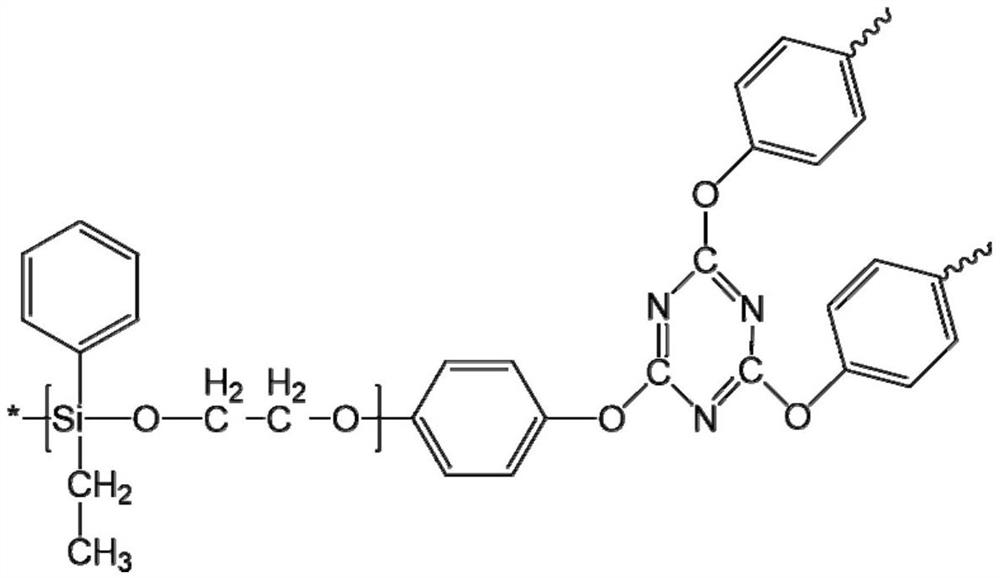

Image

Examples

Embodiment 1

[0030] In this embodiment, the heat-resistant and corrosion-resistant inert coating of graphene oxide nanosheet modified oxazine ring structure is composed of two components, A and B, in parts by weight, and the specific formula is as follows:

[0031] 1. Component A:

[0032] Ethane-1,1-bis(4-phenylcyanate): 50.0 parts;

[0033] Bisphenol S diglycidyl ether: 10.0 parts;

[0034] Polyalkylaryl silicone resin: 18.0 parts;

[0035] Surface modified graphene oxide nanosheets: 2.0 parts;

[0036] Glass flakes: 10.0 parts;

[0037] Silicon carbide powder: 8.0 parts;

[0038] Fluorosilane coupling agent: 2.0 parts;

[0039] 1,4-epoxybutane: 5.0 parts;

[0040] Among them, the graphene oxide nanosheets are few-layer graphene oxide nanosheets with ≤3 layers, and the surface modification process of the graphene oxide nanosheets is as follows: use acetic acid to adjust the pH value of deionized water to 4.5 to form an acetic acid solution, and prepare a concentration of 3wt% hept...

Embodiment 2

[0048] The difference from Example 1 is:

[0049] In this embodiment, the heat-resistant and corrosion-resistant inert coating of graphene oxide nanosheet modified oxazine ring structure is composed of two components, A and B, in parts by weight, and the specific formula is as follows:

[0050] (1) Component A:

[0051] Ethane-1,1-bis(4-phenylcyanate): 41.0 parts;

[0052] Bisphenol S diglycidyl ether: 18.0 parts;

[0053] Polyalkylaryl silicone resin: 16.0 parts;

[0054] Surface modified graphene oxide nanosheets: 1.8 parts;

[0055] Glass flakes: 10.2 parts;

[0056] Silicon carbide powder: 8.0 parts;

[0057] Fluorosilane coupling agent: 1.0 parts;

[0058] 1,4-epoxybutane: 4.0 parts;

[0059] Among them, the graphene oxide nanosheets are multilayer graphene oxide nanosheets with 5 to 10 layers, and the surface modification process of the graphene oxide nanosheets is as follows: use acetic acid to adjust the pH value of deionized water to 5 to form an acetic acid so...

Embodiment 3

[0067] The difference from Example 1 is:

[0068] In this embodiment, the heat-resistant and corrosion-resistant inert coating of graphene oxide nanosheet modified oxazine ring structure is composed of two components, A and B, in parts by weight, and the specific formula is as follows:

[0069] (1) Component A:

[0070] Ethane-1,1-bis(4-phenylcyanate): 50.0 parts;

[0071] Bisphenol S diglycidyl ether: 23.5 parts;

[0072] Polyalkylaryl silicone resin: 8.5 parts;

[0073] Surface modified graphene oxide nanosheets: 2.3 parts;

[0074] Glass flakes: 11.0 parts;

[0075] Silicon carbide powder: 9.0 parts;

[0076] Fluorosilane coupling agent: 1.6 parts;

[0077] 1,4-epoxybutane: 4.1 parts;

[0078] Among them, the graphene oxide nanosheets are few-layer graphene oxide nanosheets with ≤3 layers, and the surface modification process of the graphene oxide nanosheets is as follows: use acetic acid to adjust the pH value of deionized water to 4 to form an acetic acid solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com