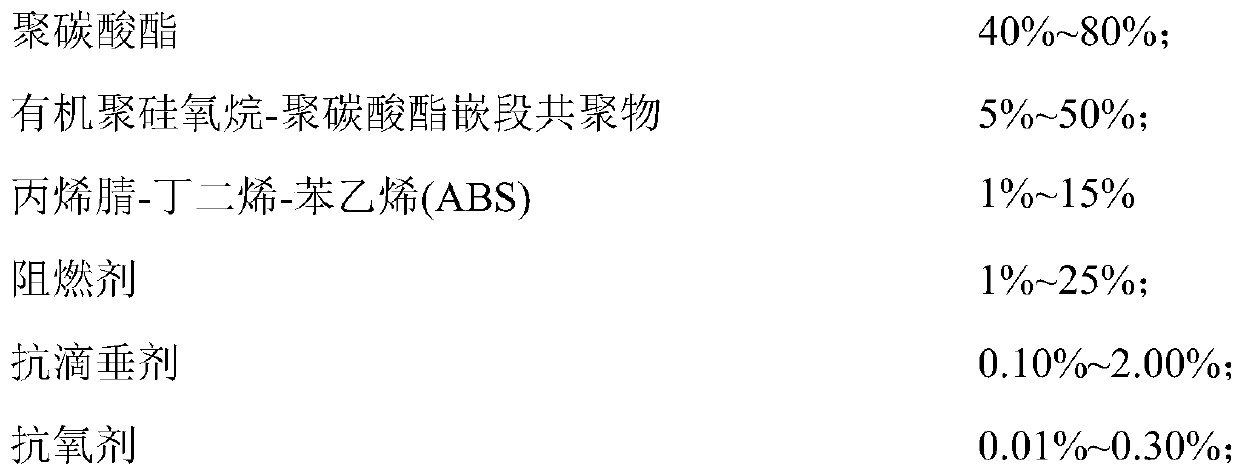

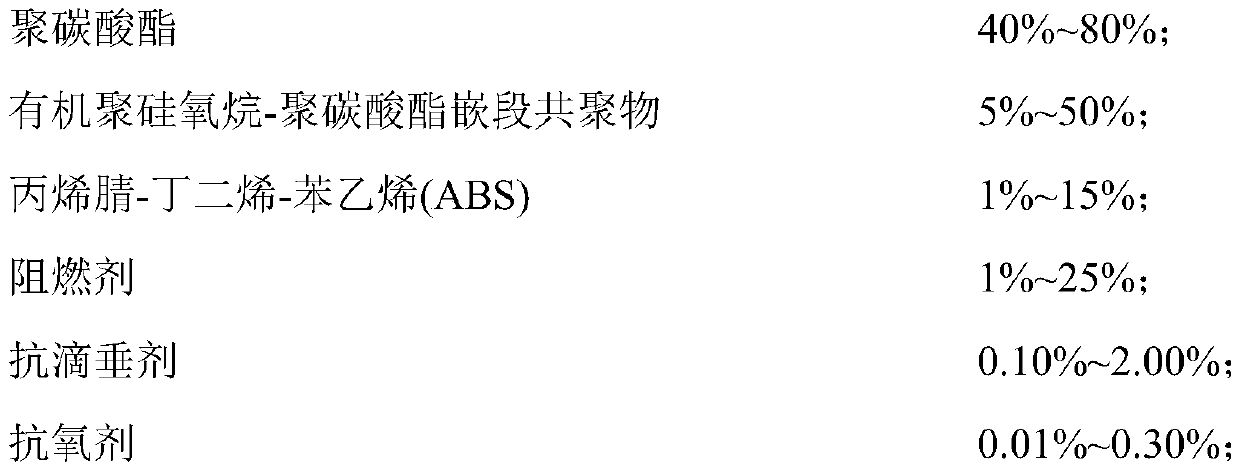

High glow wire polycarbonate composition

A polycarbonate, high glow wire technology, applied in the field of polymer materials, can solve the problems of reduced physical strength, reduced fluidity, easy overloading and heating of coil current, etc., to improve fluidity, improve carbonization, and have both physical properties. Effects of strength and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further illustrated by the following examples. It should be understood that the following examples are for illustrative purposes only, and are not intended to limit the present invention.

[0032] The following materials were used in the examples:

[0033] PC-1 means PK2870, purchased from SABIC, its MI is 2g / 10min (300°C / 1.2KG).

[0034] PC-2 means IR2500, purchased from Taihua Idemitsu, its MI is 7g / 10min (300°C / 1.2KG).

[0035] PC-3 means 2800, purchased from Covestro, its MI is 12g / 10min (300°C / 1.2KG).

[0036] PC-4 means MD1500, purchased from Taihua Idemitsu, its MI is 65g / 10min (300°C / 1.2KG).

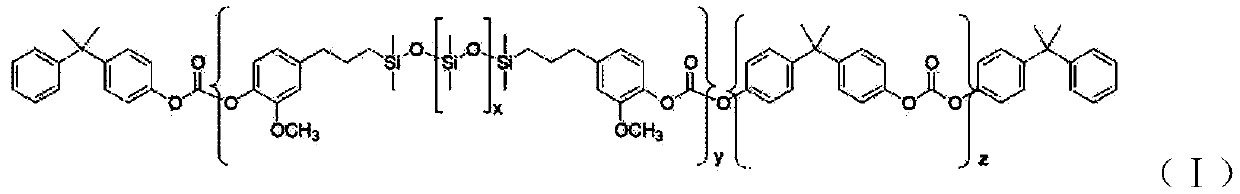

[0037] Si-PC means AG1950 was purchased from Idemitsu, Japan.

[0038] ABS means AG1000, purchased from Taihua, its MI is 0.9g / 10min (200°C / 5.0KG).

[0039] FR refers to FR-245, purchased from Israel ICL, and its Chinese name is bromotriazine (2,4,6-Tris(2,4,6-tribromophenoxy)-1,3,5triazine).

[0040] PTFE means A3800, purchased...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com