Method for preparing high-homogeneity spandex through continuous polymerization

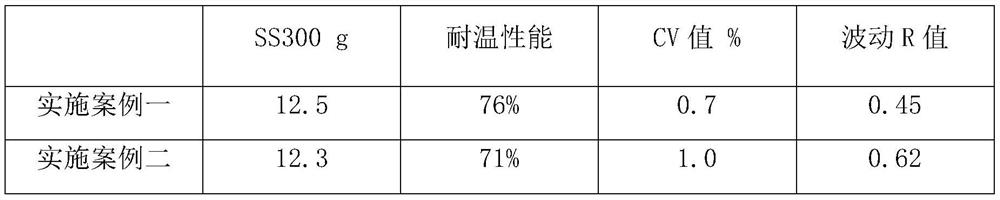

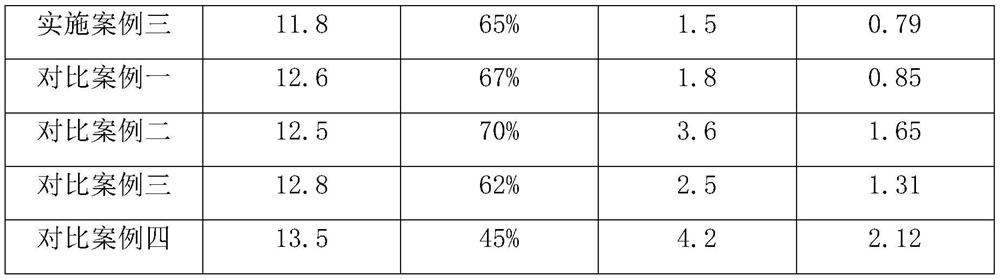

A spandex and uniform technology, which is applied in the field of continuous polymerization to prepare high-uniform spandex, can solve the problems of insufficient effect in industrial application and lack of holistic research in spandex production process, and achieve improved structural regularity and uniformity, dynamic unwinding The effect of reducing the CV value of the stress variation coefficient and the small stress fluctuation R value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0030] (1) According to the flow rate of polytetramethylene ether glycol 476.7g / min, diphenylmethane diisocyanate 110.9g / min and phosphoric acid 0.6g / min, continuously add the three into the tubular static mixer Mixing, reacting and cooling to obtain a prepolymer;

[0031] (2) According to the flow rate of prepolymer 587.7g / min and dimethylacetamide solvent 904.2g / min, continuously and uninterruptedly join in the dynamic mixer A and carry out uniform mixing, dispersion, obtain prepolymer solution; The flow rate of the polymer solution 1491.2g / min and the mixed amine solution 247.3g / min are continuously and uninterruptedly added to the dynamic mixer B to carry out the amine reaction. The chain extender in the mixed amine is ethylenediamine, and the permanent chain terminator is Cyclooctylamine, the molar ratio of amine end groups of ethylenediamine to cyclooctylamine is 22:1; the addition of excess amine is controlled to obtain a polyurethaneurea solution with an apparent visco...

Embodiment example 2

[0034] (1) According to the flow rate of polytetramethylene ether glycol 556.1g / min, diphenylmethane diisocyanate 129.4g / min and acetyl chloride 1.4g / min, the three are continuously added to the tubular static mixer Mixing, reacting and cooling in to obtain the prepolymer;

[0035] (2) According to the flow rate of prepolymer 685.6g / min and dimethylacetamide solvent 1054.9g / min, continuously and uninterruptedly join in the dynamic mixer A and carry out uniform mixing, dispersion, obtain prepolymer solution; The flow rate of the polymer solution 1740.5g / min and the mixed amine solution 288.6g / min are continuously and uninterruptedly added to the dynamic mixer B for amine reaction. The chain extender in the mixed amine is 1,3-propylenediamine, which is permanent The chain terminator is octadecylamine, and the molar ratio of amine end groups between 1,3-propanediamine and octadecylamine is 30:1; the addition of excess amine is controlled to obtain a polyurethaneurea solution with...

Embodiment example 3

[0038] (1) According to the flow rate of polytetramethylene ether glycol 476.7g / min, diphenylmethane diisocyanate 110.9g / min and phosphoric acid 0.6g / min, continuously add the three into the tubular static mixer Mixing, reacting and cooling to obtain a prepolymer;

[0039] (2) According to the flow rate of prepolymer 587.7g / min and dimethylacetamide solvent 904.2g / min, continuously and uninterruptedly join in the dynamic mixer A and carry out uniform mixing, dispersion, obtain prepolymer solution; The flow rate of the polymer solution 1491.2g / min and the mixed amine solution 247.3g / min are continuously and uninterruptedly added to the dynamic mixer B to carry out the amine reaction. The chain extender in the mixed amine is ethylenediamine, and the permanent chain terminator is Cyclooctylamine, the molar ratio of amine end groups of ethylenediamine to cyclooctylamine is 18:1; the addition of excess amine is controlled to obtain a polyurethaneurea solution with an apparent visco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com