Preparation method and application of coated S-Fe/Co@C bimetallic catalyst derived from ZIF-67

A ZIF-67, bimetallic catalyst technology, applied in the field of catalysis, can solve the problems of poor stability, more metal ion leaching, and lower metal ion leaching rate, etc., to solve poor stability, enhance electron transfer rate, and solve oxidation and agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a method for preparing a ZIF-67-derived encapsulated S-Fe / Co@C bimetallic catalyst, which specifically includes the following steps:

[0027] Step 1, 1.45g ferric chloride hexahydrate and 100mg polyvinylpyrrolidone are dissolved in the three-necked flask that 60mL 70% ethanol solution is housed, then the mixture is heated under N 2 Stir at room temperature under atmosphere for 30 minutes. Among them, polyvinylpyrrolidone was used as a dispersant; subsequently, a fresh reducing solution prepared by dissolving 0.7 g of sodium borohydride and 2.35 g of sodium dithionite in 20 mL of deionized water was added dropwise into a three-necked flask. Put the mixture in N 2 Stirring was continued for 30 minutes. Finally, the black product was separated using a magnet, and the product was washed three times each with ethanol and deionized water to remove excess sodium borohydride and sodium dithionite. The final black solid was vacuum-dried overnight in a...

Embodiment 2

[0036] This example provides a method for degrading tetrabromobisphenol A in groundwater by activating PMS with a ZIF-67-derived encapsulated S-Fe / Co@C bimetallic catalyst, which specifically includes the following steps:

[0037] Step 1. The degradation experiment was carried out in a 100 ml serum bottle at room temperature. The bimetallic catalyst S-Fe / Co@C (0.2g L -1 ) into TBBPA solution (20mg·L -1 )middle. After 30 minutes, a certain volume of PMS (0.6mM·L -1 ) solution to start the reaction. At specified time intervals, collect 1mL solution samples during the experiment, and immediately add 1mL methanol to terminate the reaction, and detect the remaining concentration of tetrabromobisphenol A.

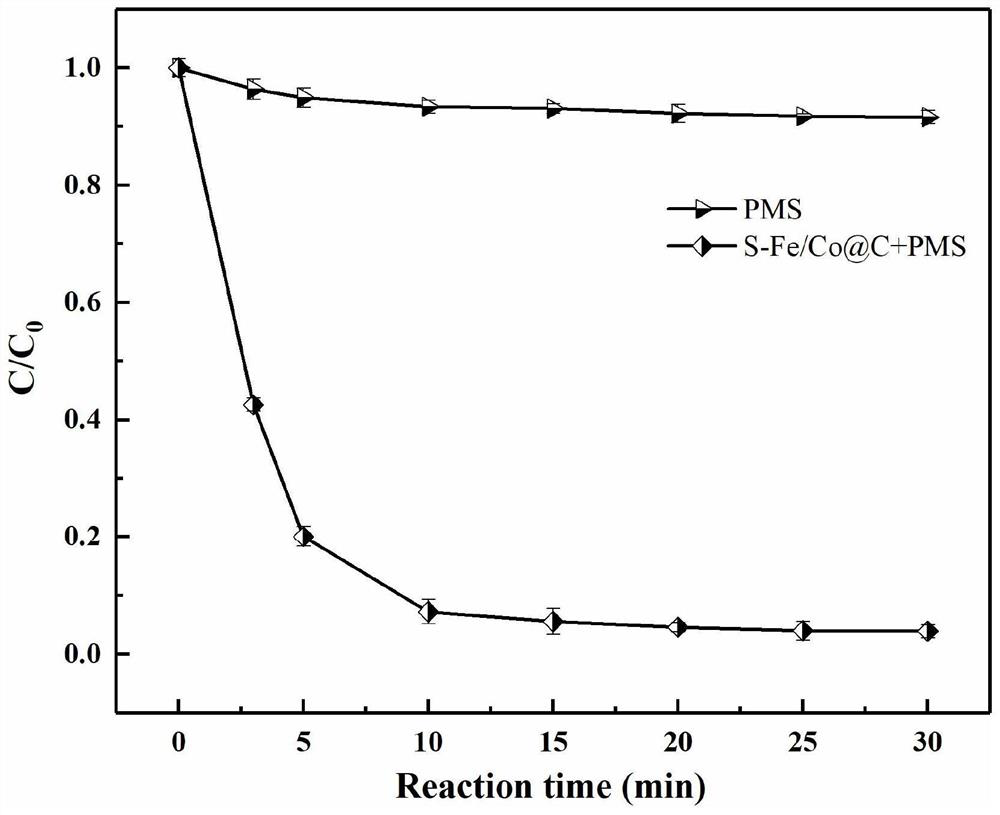

[0038] Such as image 3 Shown is the degradation effect diagram of the ZIF-67-derived encapsulated S-Fe / Co@C bimetallic catalyst activated by PMS to remove tetrabromobisphenol A in groundwater prepared by the present invention. The PMS system alone could only directly remov...

Embodiment 3

[0040] This embodiment provides a kind of ZIF-67 derived encapsulation type S-Fe / Co@C bimetallic catalyst activation PMS ion leaching rate in the process of degrading TBBPA, specifically comprises the following steps:

[0041] The solution after the reaction in Example 2 was taken, and the concentration of iron ions and cobalt ions leached in the solution was measured by inductively coupled plasma technology.

[0042] Figure 4For the leaching rate of cobalt ion and iron ion after the material degradation reaction of the present invention, it is found that the cobalt ion and iron ion of leaching are all far lower than the discharge limit value (cobalt ion: < 1.0mg / L and iron ion: <0.3 mg / L). It fully demonstrates that S-Fe / Co@C has a low ion leaching rate and has no secondary pollution to the environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com