Preparation process of bar for large-size hot extrusion of EMS1 martensitic gas valve steel

A preparation process and technology of valve steel, which is applied in the field of metal processing, can solve the problems of inability to automatically rotate materials, low precision of straightening machines, and increased labor costs, so as to improve shape and distribution, save energy and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The invention provides a technical solution: a preparation process of a bar for large-scale hot extrusion of EMS1 martensitic valve steel. The bar is composed of the following parts by weight: scrap steel 100-150 parts, high-carbon ferrochrome 60- 90 parts, 50-80 parts of lime coating solution, 10-15 parts of carbon powder and 10-15 parts of ferrosilicon powder, the specific steps of its preparation process are as follows:

[0039] Step 1: Add 100-150 parts of scrap steel and 60-90 parts of high-carbon ferrochrome in the electric arc furnace, and then carry out the melting of the alloy for primary refining to form molten steel;

[0040] Step 2: Put the molten steel into the ladle refining furnace, adjust the alloy composition, and add 10-15 parts of carbon powder and 10-15 parts of ferrosilicon powder in batches successively, heat up and refine, deoxidize, and then take samples for analysis. When each alloy composition reaches National standard requirements, when the te...

Embodiment 2

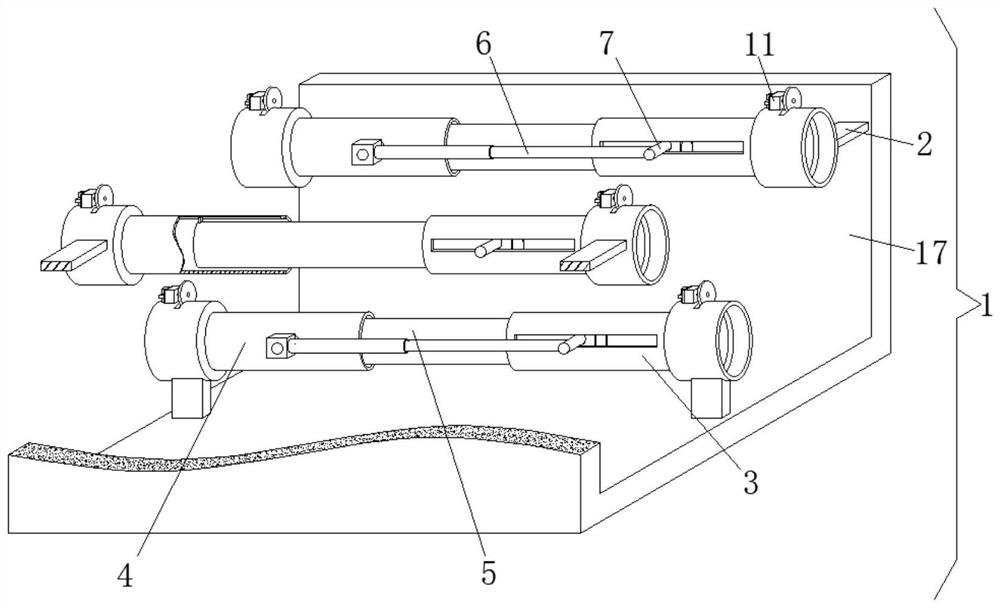

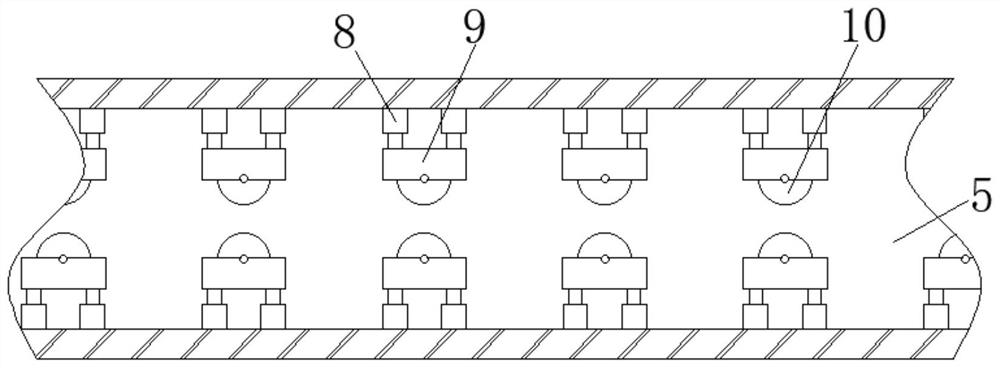

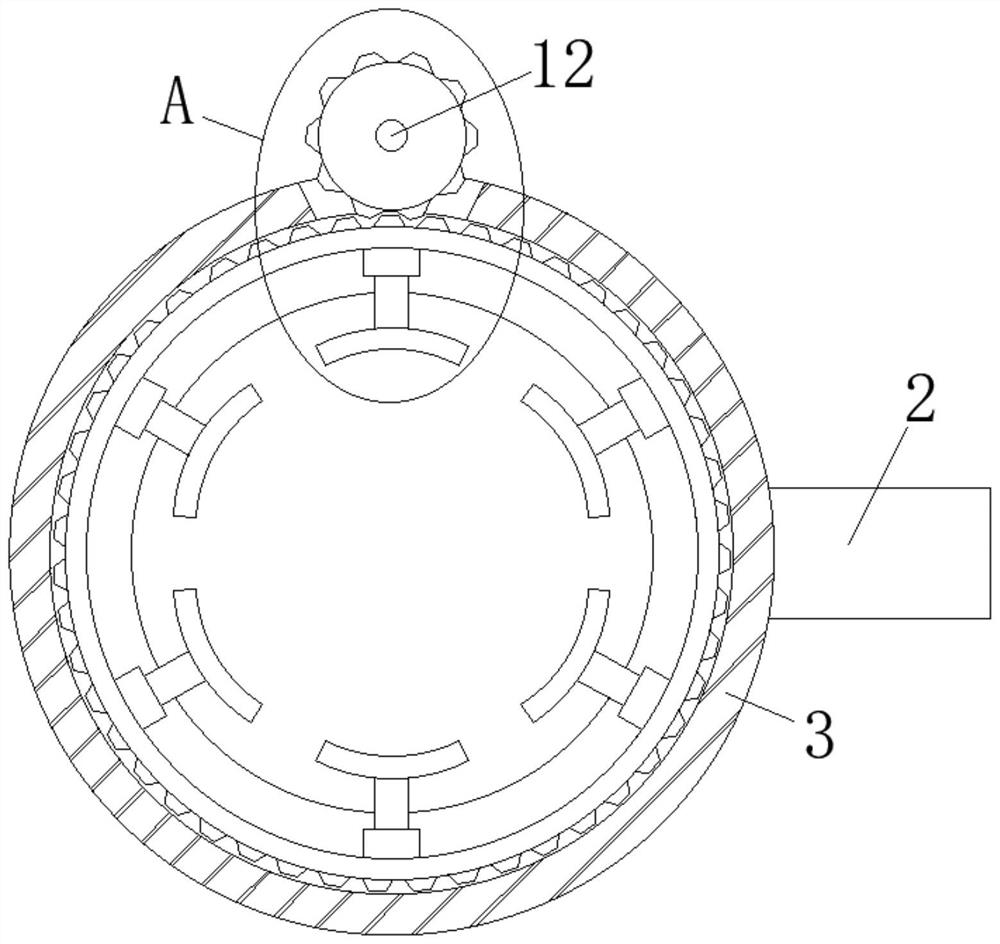

[0053] see figure 1 and figure 2 In this embodiment, the straightening machine 1 includes a housing 17, the inner side wall of the housing 17 is fixedly connected with a joint block 2, and the other end of the joint block 2 is respectively fixed with a fixed sleeve 3 and a fixed sleeve 2 4, and the fixed sleeve A moving sleeve 5 is slidingly sleeved between the first 3 and the fixed sleeve two 4, and a chute is provided on the side wall of the fixed sleeve one 3, and an electric push rod one 6 is installed on the side wall of the fixed sleeve two 4, and the electric push rod one 6 is installed on the side wall of the fixed sleeve two 4. The other end of rod one 6 is fixedly connected with connecting rod 7, and the other end of connecting rod 7 extends in the fixed cover one 3, and the extension end of connecting rod 7 is affixed with the side wall of moving cover 5; An electric push rod two 8 is installed on the top, and the other end of the electric push rod two 8 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com