Kerosene co-catalytic pyrolysis-semicoke catalytic gasification method

A technology of co-catalysis and kerosene, applied in the field of coal pyrolysis, to achieve the effects of simple production process, improved gasification efficiency and high-efficiency pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

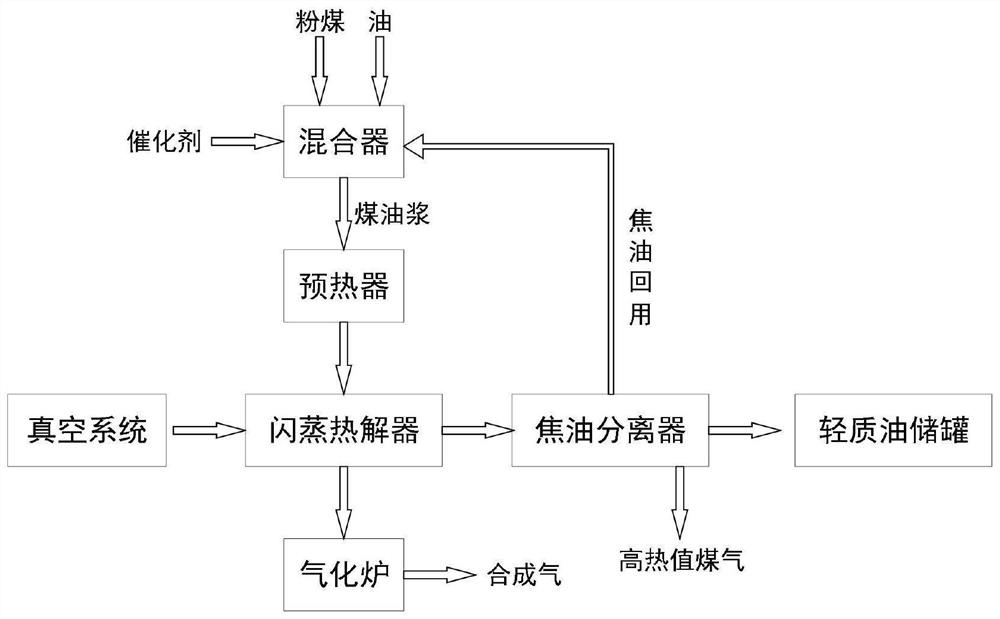

[0024] A method for kerosene co-catalytic pyrolysis-semi-coke catalytic gasification, the method comprising:

[0025] The coal sample is crushed into coal powder with a particle size of 1-1000 μm. The coal sample is mixed with lignite, hematite, medium and low temperature coal tar and coal powder at a mass ratio of 0.2:30:100 to obtain a kerosene slurry. The heater is preheated to 300°C, and then enters the flash pyrolyzer for reaction, the pressure is kept at 1kPa, and the residence time is 1h, so that the volatile matter of kerosene co-pyrolysis can fully escape, and the volatile matter of kerosene slurry flash pyrolysis enters the tar In the separator; after the volatile matter escapes from the flash pyrolysis of the kerosene slurry, the remaining components are polycondensed by the flash pyrolyzer to obtain solid semi-coke, which is broken and sent to the gasifier. 10°C / min to heat up to 900-1200°C, with CO 2 as a gasification agent to obtain syngas CO and H 2 ; Through ...

Embodiment 2

[0028] A method for co-catalyzed pyrolysis of kerosene-semi-coke catalytic gasification is basically the same as in Example 1, the difference is that the raw materials are bituminous coal, laterite nickel ore and high-temperature coal tar, and the quality of laterite nickel ore, high-temperature coal tar and coal powder The ratio is 0.1:100:100, and the residence time in the flash pyrolyzer is 0.3h.

[0029] By comparing the two raw materials (without adding catalyst), the theoretically calculated value of the pyrolysis tar yield is 4.34% higher than the calculated value, and the n-hexane soluble matter is 3.86% higher than the calculated value.

Embodiment 3

[0031] A method for kerosene co-catalytic pyrolysis-semi-coke catalytic gasification is basically the same as in Example 1, the difference being that the raw materials are lignite, hematite and petroleum crude oil, and the mass ratio of hematite, petroleum crude oil and pulverized coal is 0.5:50:100, the preheater is preheated to 350°C, and the residence time in the flash pyrolyzer is 0.1h.

[0032] The tar is collected in the tar collection tank at the front of the vacuum system, and the tar is dehydrated to calculate the yield. By comparing the two raw materials (without adding catalyst), the theoretically calculated value of the pyrolysis tar yield is 2.37% higher than the calculated value, and the n-hexane soluble matter is 4.05% higher than the calculated value. From 40 to 1200°C, with a heating rate of 10°C / min, with CO 2 As a gasification agent, it is found that the maximum and constant peak temperature of the gasification decreases by 23°C through the gasification of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com