Method for preparing attapulgite-based biodegradable plastic

A technology for attapulgite and degradable plastics, applied in the field of biodegradable plastics, can solve the problems of high price, high production cost, poor mechanical properties, etc., and achieve the effects of less by-products, good thermal properties, and accelerated material circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

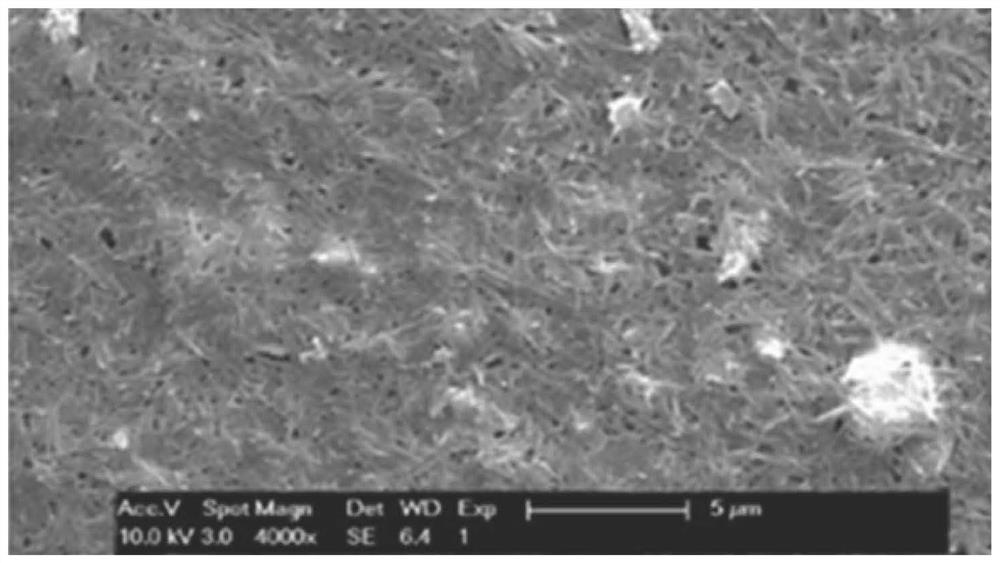

Image

Examples

Embodiment 1

[0027] 1. Pour the embossing stone with 3-aminopropyltriethoxysilane 1: 100 into the beaker, stirred at 50 ° C for 6 hours, then filtered, dried, and ground, and then functionally modified and actuated; 10.0 G functionalized modified refropab, 1 g starch biological polymer material, 1 gtiO2 photocatalytic material added to 50 mL of deionized water, mixed 60 min, vacuum filtration, and dried under the obtained filter residue vacuum drying for 12 h to obtain starch / TiO2 / change Decorative revenue composite powder is obtained by treating a dilot composite material, grinding, and sieve.

[0028] 2. The obtained functionalized modified dipper composite powder 10g and 100 g of polylactic acid high polymer material; 100 GPLA is added to the mesh for 2 min, then 10g functionally modified recess composite powder is blended for 5 min. To make 10% biodegradable modified masterbatch.

[0029] 3. The resulting 10% biodegradable modified masterbatch is entered into the injection molding mach...

Embodiment 2

[0037] 1. Filter, dry, dry, and ground after 2.5 mol / L hydrochloric acid, and then functionally modified reforiental stone; 10.0 g of functionalized modified concave-resistant stone, 1 g of cellulose bio-polymer material, 1 g of a tin oxide photocatalytic material was added to 50 ml of deionized water to mix 60 min and vacuum filtration, and the obtained filter residue vacuum drying box was dried 12 h to obtain cellulose / tin oxide / modified dipped material, grinding, sieve Treatment, that is, the functionalized modified recess composite powder is obtained.

[0038] 2. The obtained functionalized modified dipper composite powder 10g and 100 g of polylactic acid high polymer material; 100 GPLA is added to the mesh for 2 min, then 10g functionally modified recess composite powder is blended for 5 min. To make 10% biodegradable modified masterbatch.

[0039] 3. The resulting 10% biodegradable modified masterbatch is entered into the injection molding machine, and the granulation ...

Embodiment 3

[0044] 1. Differentially modified relevancestone stone after gas treatment after 150 ° C; 5G functionally modified refropab stone, 1 g lignin biometric material, 1 g of zinc oxide photocatalytic material to 100 ml After stirring in deionized water, mixed 60 min and vacuum filtration, dried under the obtained filter residue vacuum drying case to obtain a lignin / zinc oxide / modified dipping composite material, grinding, sieve, and other step processing, i.e., a functional modified concave Soil complex powder.

[0045] 2. 10 g of the obtained functionalized modified dipper compound powder was added to the beaker with 100 g pva. Distilled water was added, stirred at room temperature under magnetic stirring for 6 h to 24 h, and the solution was splitted and passed on.

[0046]3. Pour the modified dipper / polymer solution into the mold, naturally evaporate 24 h at room temperature, and remove a large amount of water.After drying at 50 ° C for 24 h, it was dried in vacuo at 100 ° C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com