Crystalline graphene as well as preparation method and application thereof

A technology of graphene and crystal form, which is applied in the field of crystalline graphene and its preparation, can solve the problems of reduced macroscopic performance, poor environmental protection effect, and small specific surface area of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

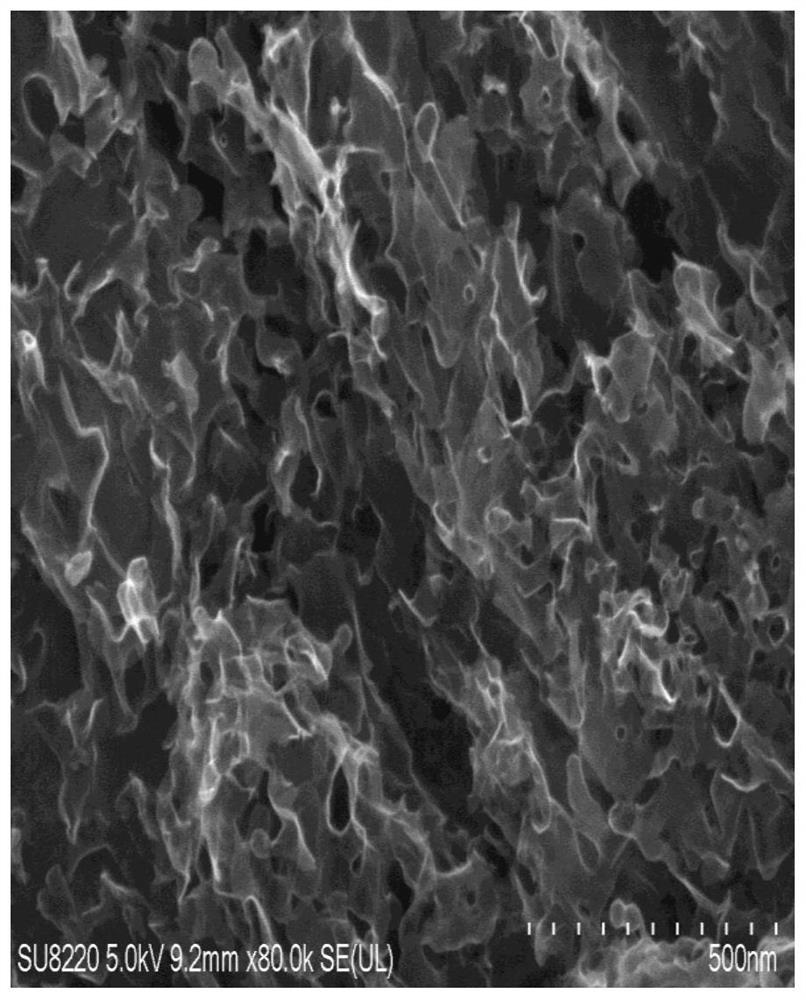

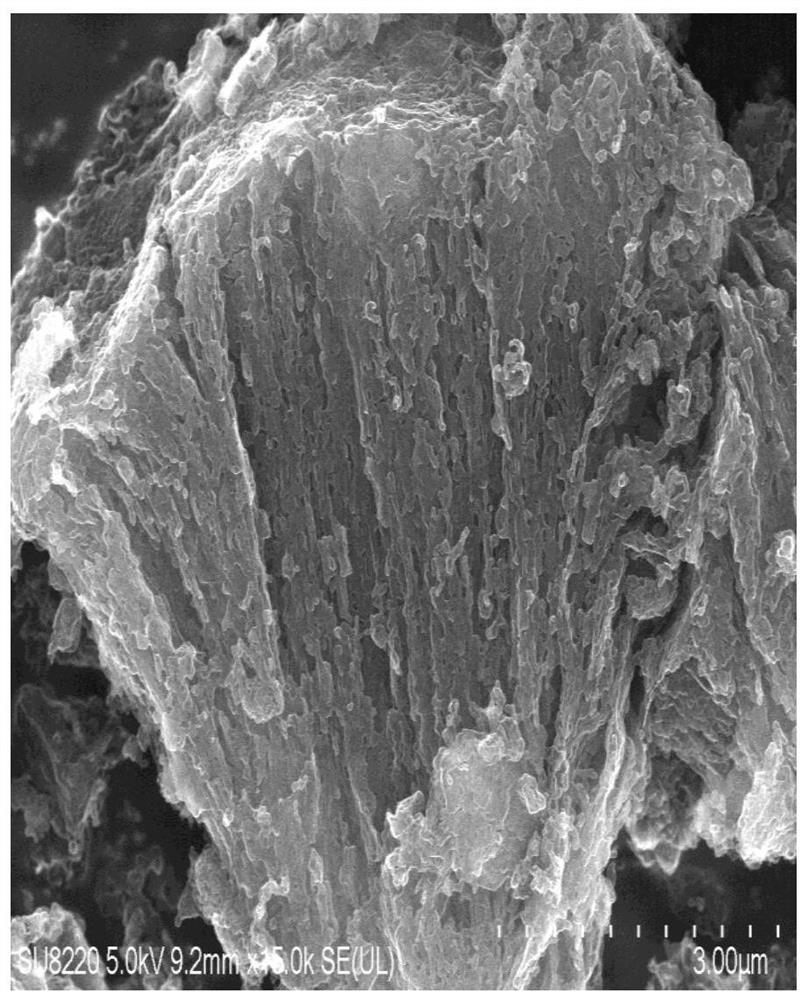

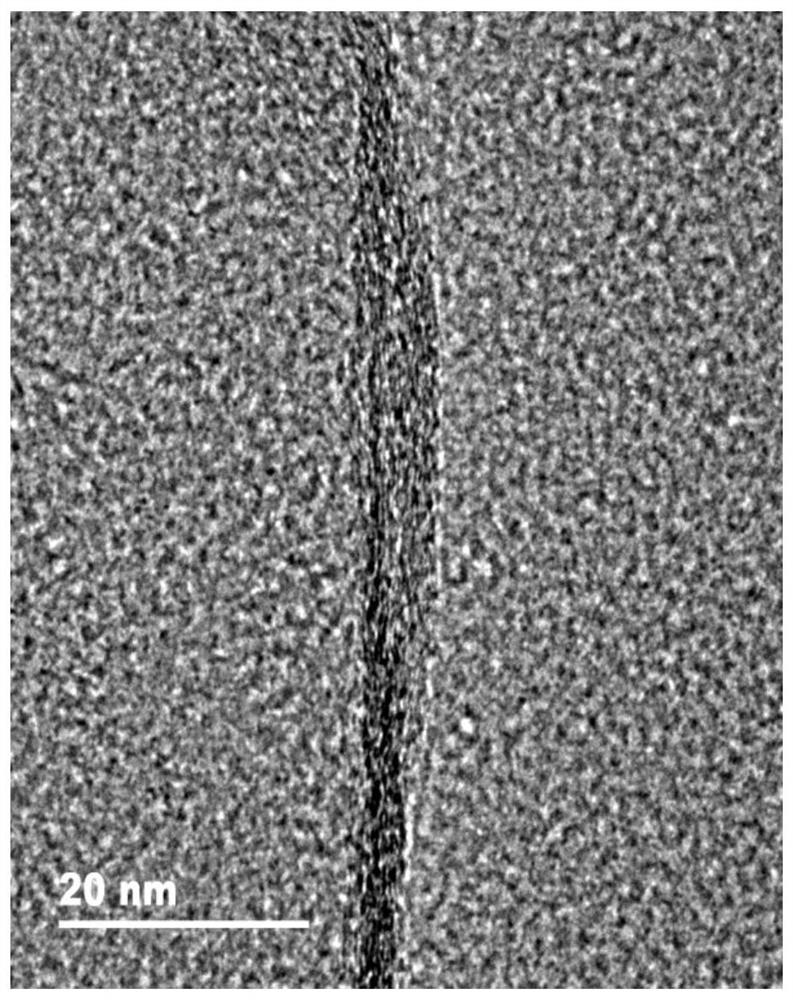

Image

Examples

preparation example Construction

[0037] The preparation method of crystalline graphene of the present invention, concrete steps are as follows:

[0038] (1) The highly active Ca(OH) 2 The powder is placed in a reaction furnace, heated to a preset temperature under an inert protective atmosphere and maintained at this temperature; in terms of mass percentage, highly active Ca(OH) 2 Ca(OH) in powder 2 The content is not less than 90%, Mg(OH) 2 The content is between 0.1% and 5%, and the rest are impurities;

[0039] (2) Feed an appropriate amount of carbon source into the reaction furnace at a certain flow rate at the preset temperature, wait for the chemical vapor deposition reaction for 5 seconds to 5 minutes, and generate a solid phase product, then cool down to below 100°C, and take out the solid phase product in the furnace. Phase product;

[0040] (3) Soak the solid phase product obtained in step (2) in hydrochloric acid solution for pickling, react at room temperature to 70°C for 10 minutes to 20 hou...

Embodiment 1

[0047] The particle size above 300 mesh containing 0.5% Mg(OH) 2 Ca(OH) 2 Put 50g of powder in the rotary furnace, in the nitrogen atmosphere, raise the temperature of the furnace to 950°C at a heating rate of 10°C / min and maintain the temperature, keep the rotating speed of the rotary furnace at 4 rpm, and flow to the furnace at a flow rate of 3ml / min. Inject 4ml of n-hexane into the furnace, and after chemical vapor deposition for 5 minutes, cool the rotary furnace to 100°C under nitrogen protection, take out the black solid phase product, fully react with 30% hydrochloric acid solution in the reaction kettle, and keep the reaction kettle at a constant temperature of 60°C After 5 hours, filter and rinse repeatedly with deionized water. When the pH of the filtrate is 7, dry the filter residue in a drying oven at 100°C to obtain crystalline graphene wool. The crystalline graphene wool is placed in a tubular atmosphere furnace, etched at 600°C for half an hour in an atmosphere...

Embodiment 2

[0049] The particle size above 400 mesh containing 0.5% Mg(OH) 2 Ca(OH) 2 Put 50g of powder in the rotary furnace, in the nitrogen atmosphere, raise the temperature of the furnace to 950°C at a heating rate of 10°C / min and maintain the temperature, keep the rotating speed of the rotary furnace at 4 rpm, and flow to the furnace at a flow rate of 3ml / min. Inject 4ml of cyclohexane into the furnace, after chemical vapor deposition for 2 minutes, cool the rotary furnace to 100°C under the protection of nitrogen, take out the black solid phase product, fully react with 20% hydrochloric acid solution in the reactor, and keep the reactor at 60°C Keep the temperature for 8 hours, then filter, rinse repeatedly with deionized water, and when the pH of the filtrate is 7, dry the filter residue in a drying oven at 100°C to obtain crystalline graphene wool. The crystalline graphene wool is placed in a tubular atmosphere furnace, etched at 950°C for 20 minutes in an atmosphere containing 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com