A kind of preparation method of copper-based composite material for resistance welding electrode

A copper-based composite material, resistance welding technology, applied in welding/cutting media/materials, welding equipment, manufacturing tools, etc., can solve the problems of inability to meet the normal use of materials, insufficient strength and hardness, short service life, etc. The effect of high density, fast heating speed and uniform temperature indexing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

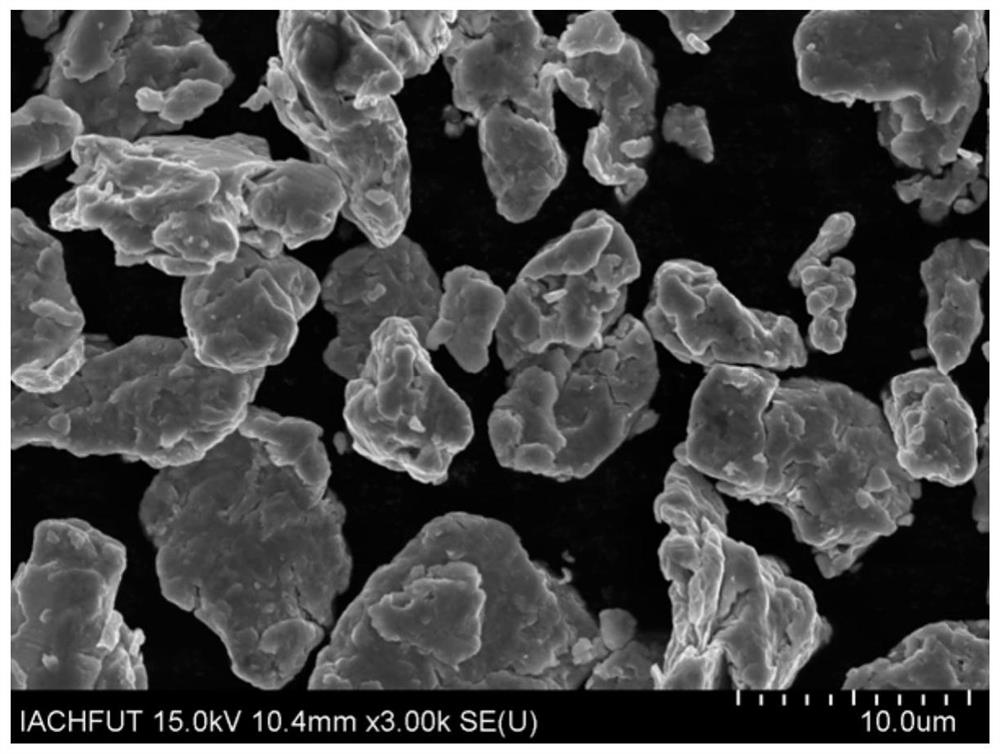

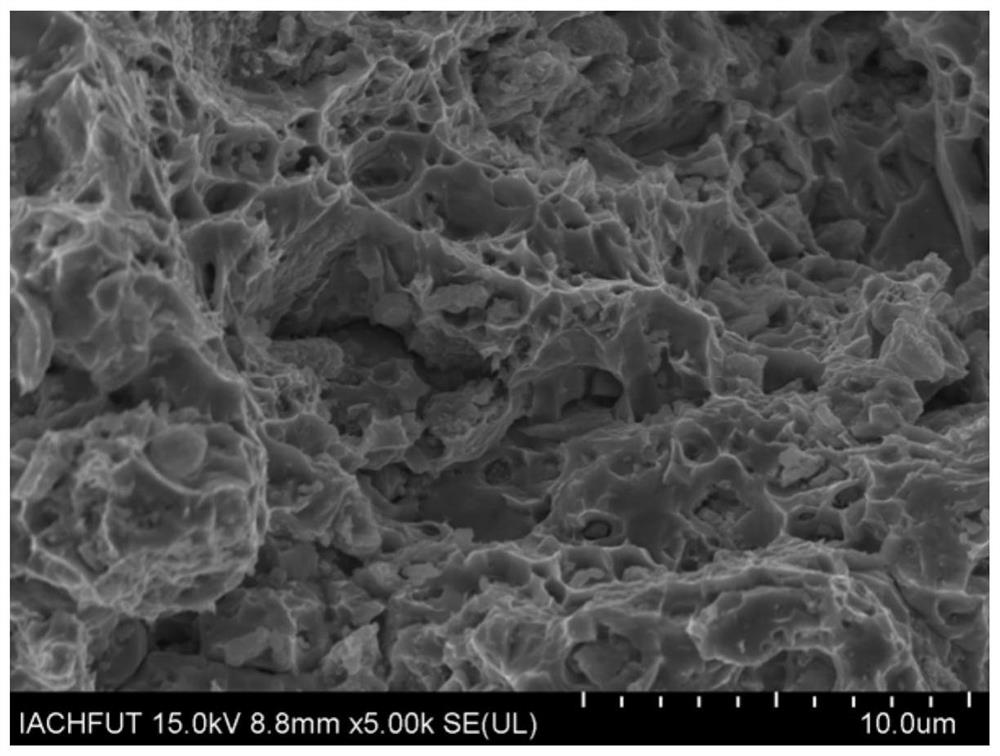

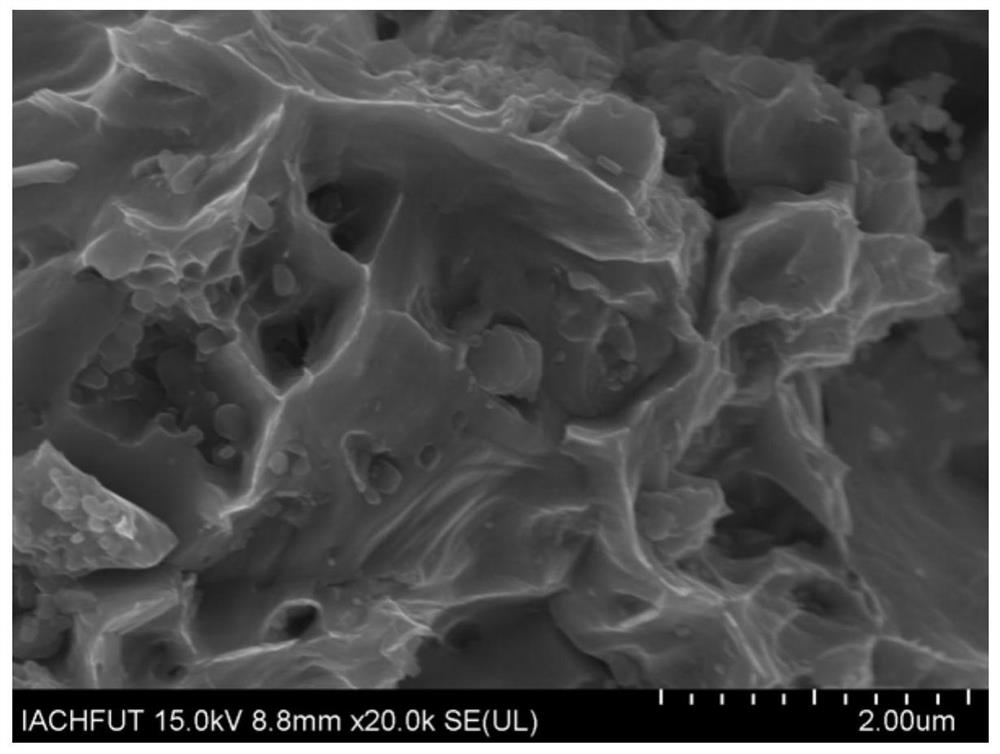

[0023] CuCrZr-(WC-Y in this embodiment 2 o 3 ) composite material, which is made by carbonization, ball milling, calcining reduction and spark plasma sintering, wherein WC-Y 2 o 3 The mass fraction of is 1%.

[0024] CuCrZr-(WC-Y in this embodiment 2 o 3 ) The preparation method of composite material is as follows:

[0025] 1. Carbonization: W-0.5%Y 2 o 3 The powder and carbon powder are mixed in a QM-QX4 omnidirectional planetary ball mill, in which the atomic number of carbon is 110% of that of tungsten, the ball milling speed is 400r / min, the ball milling time is 15h, the ball-to-material ratio is 10:1, and the ball milling time is 10:1. Then put it in a ceramic burning boat and put it in a GSL-1700X high-temperature tubular sintering furnace, and carry out carbonization under an argon atmosphere to obtain WC-Y 2 o 3 powder, the carbonization temperature is 1200°C, and the holding time is 2h.

[0026] 2. Ball milling: mix CuCrZr with WC-Y 2 o 3 The powder is pla...

Embodiment 2

[0030] CuCrZr-(WC-Y in this embodiment 2 o 3 ) composite material, which is made by carbonization, ball milling, calcining reduction and spark plasma sintering, wherein WC-Y 2 o 3 The quality fraction is 3%.

[0031] CuCrZr-(WC-Y in this embodiment 2 o 3 ) The preparation method of composite material is as follows:

[0032] 1. Carbonization: W-0.5%Y 2 o 3 The powder and carbon powder are mixed in a QM-QX4 omnidirectional planetary ball mill, in which the atomic number of carbon is 115% of that of tungsten, the ball milling speed is 400r / min, the ball milling time is 15h, the ball-to-material ratio is 10:1, and the ball milling time is 10:1. Then put it in a ceramic burning boat and put it in a GSL-1700X high-temperature tubular sintering furnace, and carry out carbonization under an argon atmosphere to obtain WC-Y 2 o 3 powder, the carbonization temperature is 1200°C, and the holding time is 2h.

[0033] 2. Ball milling: CuCrZr and WC-Y 2 o 3 The powder is placed i...

Embodiment 3

[0037] CuCrZr-(WC-Y in this embodiment 2 o 3 ) composite material, which is made by carbonization, ball milling, calcining reduction and spark plasma sintering, wherein WC-Y 2 o 3 The quality fraction is 5%.

[0038] CuCrZr-(WC-Y in this embodiment 2 o 3 ) The preparation method of composite material is as follows:

[0039] 1. Carbonization: W-0.5%Y 2 o 3 The powder and carbon powder are mixed in a QM-QX4 all-round planetary ball mill, in which the atomic number of carbon is 120% of that of tungsten, the ball milling speed is 400r / min, the ball milling time is 15h, and the ball-to-material ratio is 10:1. Then put it in a ceramic burning boat and put it in a GSL-1700X high-temperature tubular sintering furnace, and carry out carbonization under an argon atmosphere to obtain WC-Y 2 o 3 powder, the carbonization temperature is 1200°C, and the holding time is 2h.

[0040] 2. Ball milling: CuCrZr and WC-Y 2 o 3 The powder is placed in a ball mill jar, where WC-Y 2 o 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com