Chlorine-doped titanium dioxide/carbon porous structure and preparation method thereof

A porous structure, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, carbon preparation/purification, etc., can solve the problems of difficult operation, high safety hazard, low doping ratio, etc., and achieve low price and high Battery performance, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1), with 400mg commercial TiO 2 1. Add 100 mg of citric acid monohydrate to 50 mL of deionized water, stir for 30 min to mix evenly, then add 1 g of sodium alginate under constant stirring, and stir for 6 h to obtain a uniformly mixed suspension.

[0035] Step 2), drop the above suspension into 50mL zinc nitrate solution (1mol / L) drop by drop with a dropper, after standing for 12h, filter and remove the excess solution to obtain a colloid, and after freeze-drying, the available TiO2 / Zinc Alginate Complex.

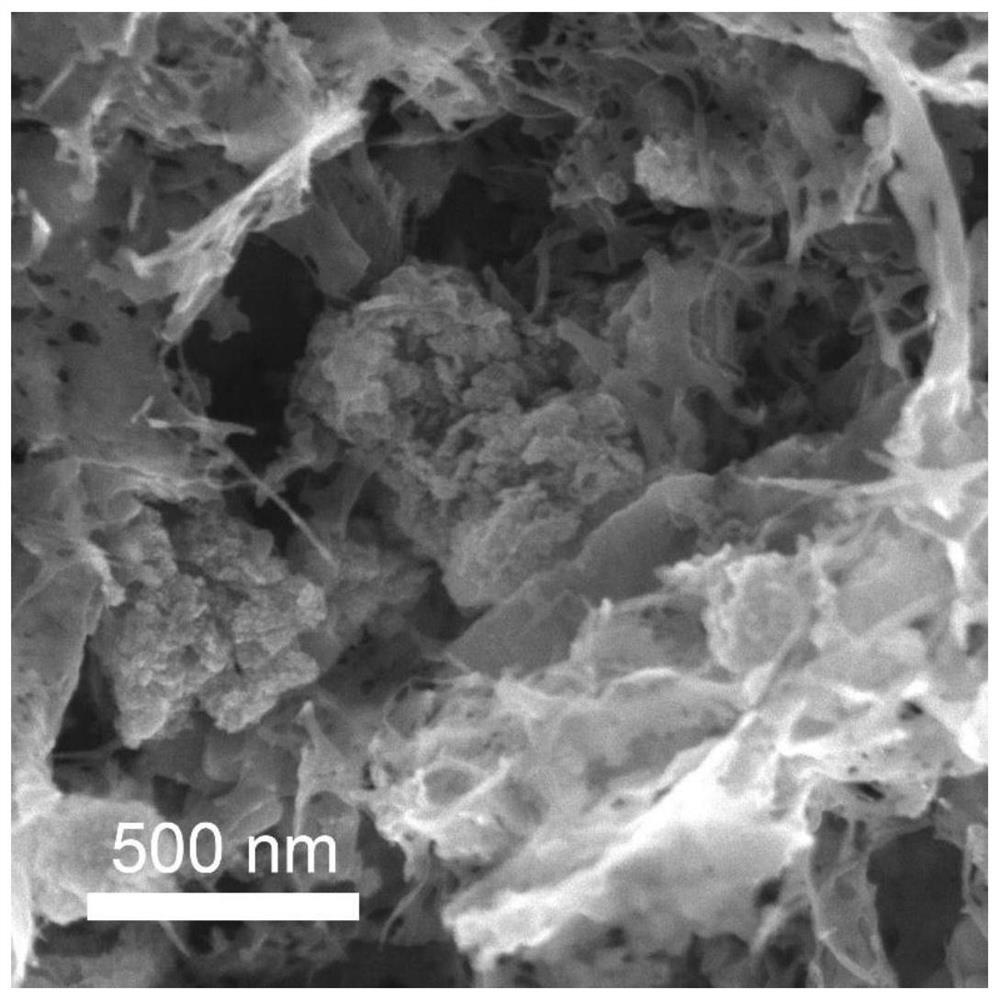

[0036] Step 3), above-mentioned TiO 2 / Zinc alginate complex is heated from room temperature to 500°C at a rate of 2°C / min in argon and kept for 2 hours, and then 1mol / L HNO 3 Soak for 12 hours to remove the zinc oxide, then centrifuge and wash with water three times, and dry at 60°C to obtain TiO 2 / C porous structure.

[0037] Step 4), the 100mg above-mentioned TiO 2 / C porous structure with 2g NH 4 Cl was mixed and ground for 10 min to make it evenly m...

Embodiment 2

[0040] Step 1), with 500mg commercial TiO 2 1. Add 100 mg of citric acid monohydrate to 50 mL of deionized water, stir for 30 min to mix evenly, then add 1 g of sodium alginate under constant stirring, and stir for 6 h to obtain a uniformly mixed suspension.

[0041] Step 2), drop the above suspension into 50mL zinc nitrate solution (1mol / L) drop by drop with a dropper, after standing for 12h, filter and remove the excess solution to obtain a colloid, and after freeze-drying, the available TiO 2 / Zinc Alginate Complex.

[0042] Step 3), above-mentioned TiO 2 / Zinc alginate complex is heated from room temperature to 500°C at a rate of 2°C / min in argon and kept for 2 hours, and then 1mol / L HNO 3 Soak for 12 hours to remove the zinc oxide, then centrifuge and wash with water three times, and dry at 60°C to obtain TiO 2 / C porous structure.

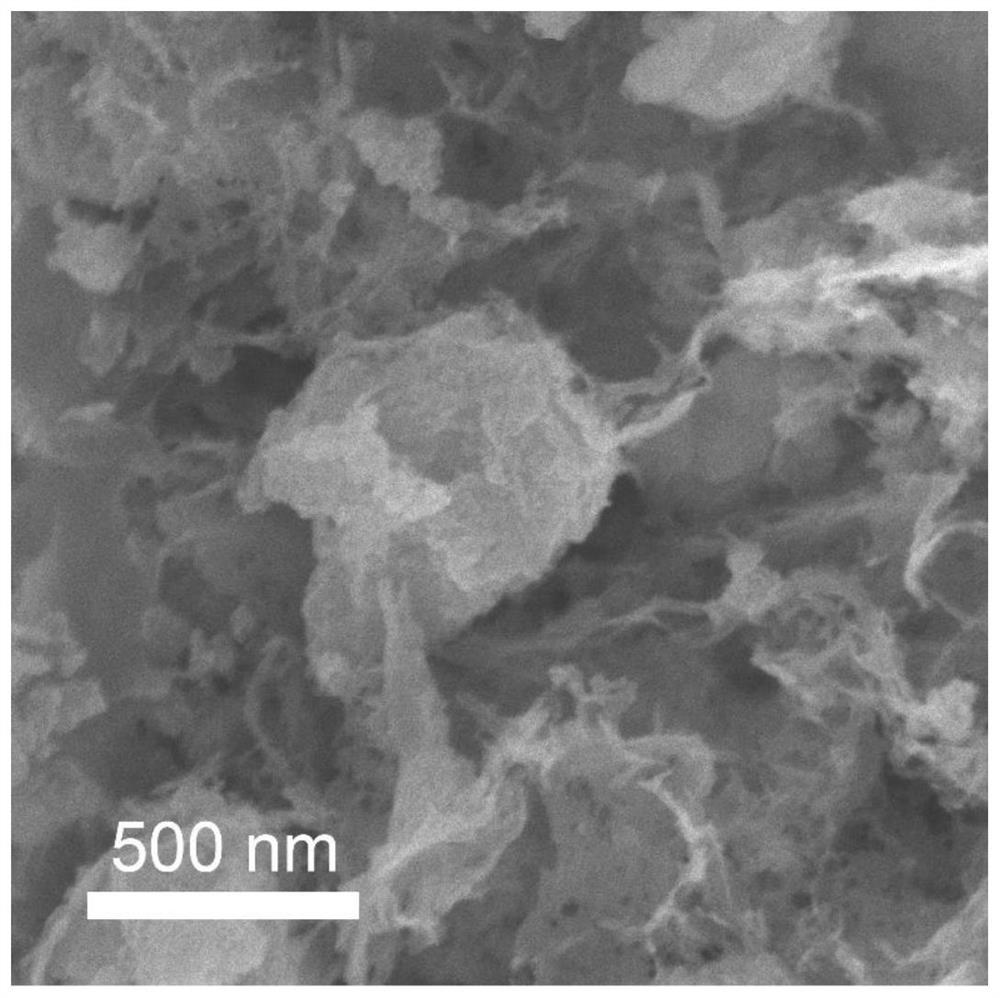

[0043] Step 4), the 100mg above-mentioned TiO 2 / C porous structure with 2g NH 4 Cl was mixed and ground for 10 min to make it evenly...

Embodiment 3

[0046] Step 1), with 600mg commercial TiO 2 1. Add 100 mg of citric acid monohydrate to 50 mL of deionized water, stir for 30 min to mix evenly, then add 1 g of sodium alginate under constant stirring, and stir for 6 h to obtain a uniformly mixed suspension.

[0047] Step 2), drop the above suspension into 50mL zinc nitrate solution (1mol / L) drop by drop with a dropper, after standing for 12h, filter and remove the excess solution to obtain a colloid, and after freeze-drying, the available TiO 2 / Zinc Alginate Complex.

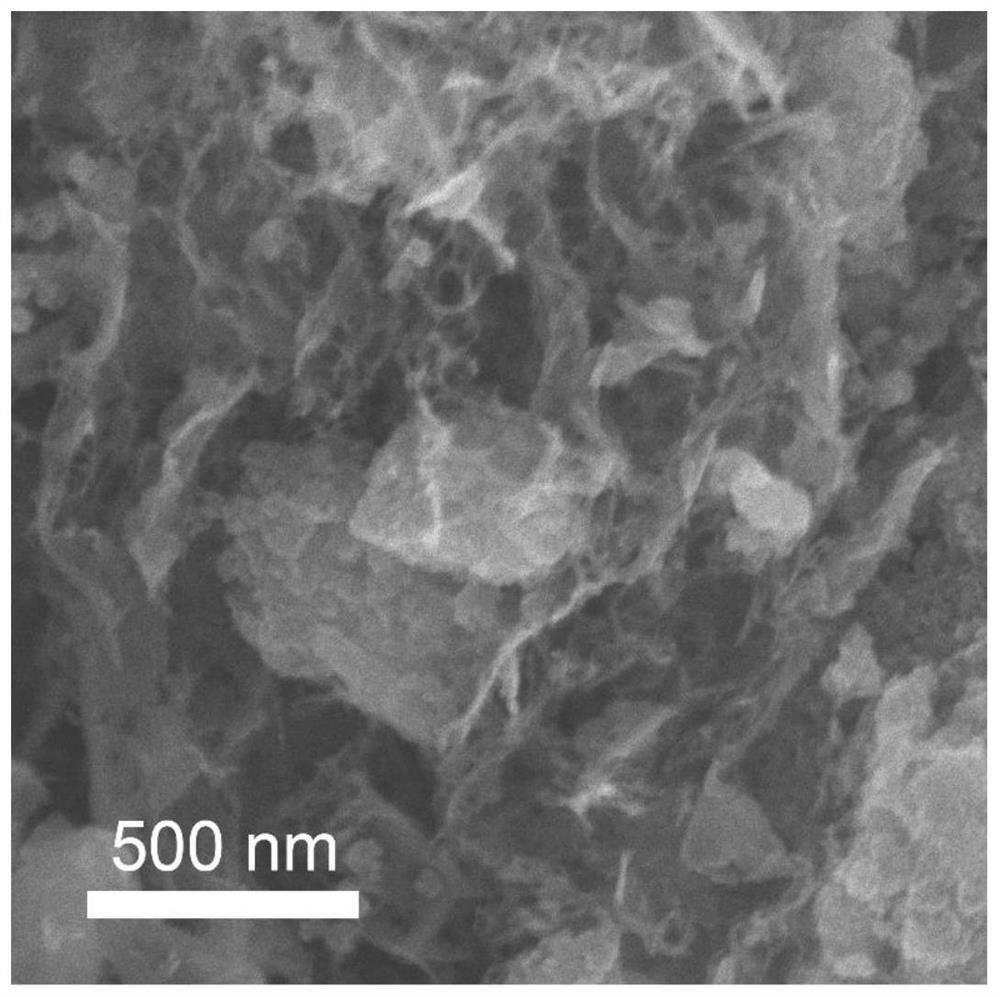

[0048] Step 3), above-mentioned TiO 2 / Zinc alginate complex is heated from room temperature to 500°C at a rate of 2°C / min in argon and kept for 2 hours, and then 1mol / L HNO 3 Soak for 12 hours to remove the zinc oxide, then centrifuge and wash with water three times, and dry at 60°C to obtain TiO 2 / C porous structure.

[0049] Step 4), the 100mg above-mentioned TiO 2 / C porous structure with 2g NH 4 Cl was mixed and ground for 10 min to make it evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com