Method for continuously preparing polymer composite multilayer plates

A sheet and core layer technology, applied in the field of continuous preparation of polymer composite multi-layer sheets, can solve the problems of harming the health of production workers, low production efficiency, pollution, etc., and achieve high production efficiency, improve production efficiency, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, continuous production five-layer composite polypropylene laminated board

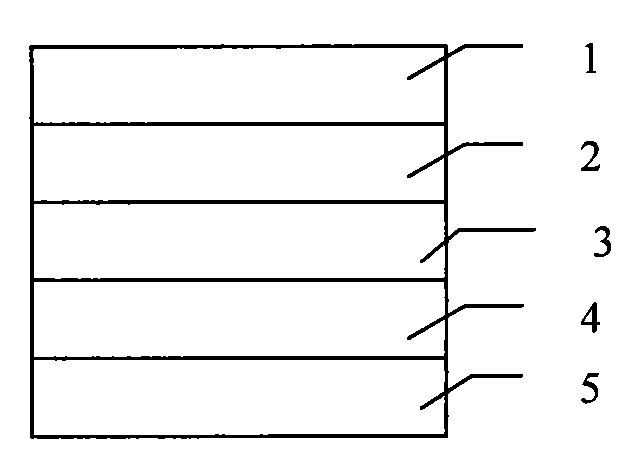

[0017] The structure of the five-layer composite PP laminate is as follows figure 1 As shown, from top to bottom are the upper skin layer 1, the upper core layer 2, the inner core layer 3, the lower core layer 4 and the lower skin layer 5. Wherein, the upper core layer 2 and the lower core layer 4 are reinforced grid cloth.

[0018] Evenly feed polypropylene (PP) into the extruder at a speed of 20kg / min for plasticizing processing. The processing temperature of the extruder is 160-220°C (heating the solid state into a viscous fluid state); after plasticizing, it is extruded The machine is continuously extruded into the plate mold, and the temperature of the mold is 140-160°C (to change the viscous flow state into a high elastic state), and extrude from the plate mold to obtain a high elastic state polypropylene (PP) sheet after molding. Then, the high elastic state polypropylene (...

Embodiment 2

[0021] Embodiment 2, continuous production five-layer composite polypropylene laminated board

[0022] The structure of the five-layer composite PP laminate is as follows figure 1 As shown, from top to bottom are the upper skin layer 1, the upper core layer 2, the inner core layer 3, the lower core layer 4 and the lower skin layer 5. The upper core layer 2 and the lower core layer 4 are reinforced grid cloth.

[0023] Evenly feed polypropylene (PP) into the extruder at a speed of 20kg / min for plasticizing processing. The processing temperature of the extruder is 160-220°C (heating the solid state into a viscous fluid state); after plasticizing, it is extruded The machine is continuously extruded into the plate mold, and the temperature of the mold is 140-160°C (to change the viscous flow state into a high elastic state). After molding, it is extruded from the plate mold to obtain a high elastic polypropylene (PP) sheet. An elastic polypropylene (PP) sheet is used as the inne...

Embodiment 5

[0036] Embodiment 5, polyethylene is the preparation of the five-layer composite polypropylene laminate of upper and lower cortex

[0037] The structure of the five-layer composite polypropylene laminate is as follows figure 1 As shown, from top to bottom are the upper skin layer 1, the upper core layer 2, the inner core layer 3, the lower core layer 4 and the lower skin layer 5. Wherein, the upper core layer 2 and the lower core layer 4 are reinforced grid cloth.

[0038] Evenly feed polypropylene (PP) into the extruder at a speed of 20kg / min for plasticizing processing. The processing temperature of the extruder is 160-220°C (heating the solid state into a viscous fluid state); after plasticizing, the polypropylene is formed The extruder is continuously extruded into the plate mold, and the temperature of the mold is 140-160°C (to change the viscous fluid state into a high elastic state). After forming, extrude from the plate mold to obtain a high elastic polypropylene (PP)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Impact height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com