REVO measuring head A-axis zero error calibration method

A technology of zero position error and calibration method, which is applied in the direction of measuring devices and instruments, can solve problems such as the impact of calibration accuracy, and achieve the effects of easy operation and realization, simple and easy method, and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

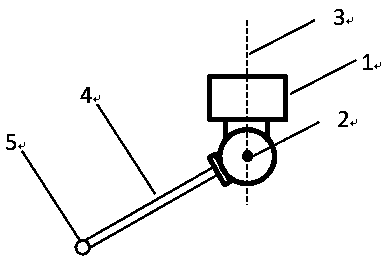

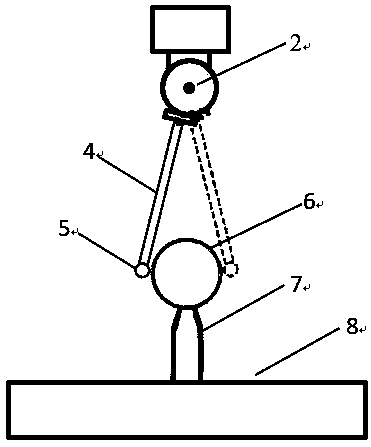

[0025] like figure 1 , figure 2 As shown, a REVO probe A-axis zero error calibration method of the present invention is used in the REVO five-axis measurement system, and the tools used include: a flat plate 8 and a standard ball 6 . Plate 8 is a 00-grade granite plate, and the flatness of the working surface is 2.1 μm. The material of the standard ball 6 is ceramics, and the diameter D is 44.9983mm. The specific steps of the method are as follows:

[0026] S1. Standard ball 6 is fixed on the flat plate 8 that is placed horizontally by club 7;

[0027] S2. Turn the probe 4 to the vertical direction, move the measuring machine spindle X to detect a point on the equator of the standard ball 6, and record the detection point x to and z to the coordinate value ( x 1 , z 1 ), move the measuring machine spindle X and spindle Z, so that the coordinate values of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com