Coated die for use in hot stamping

A hot stamping and coating technology, applied in the direction of forming tools, manufacturing tools, sputtering coating, etc., can solve the problems of hardness reduction, reduction, change, etc., and achieve excellent wear resistance and seizure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] First, the aggregation resistance was evaluated by simulating the initial stage of hot stamping.

[0049] As for the base material, prepare the base material of high-speed steel SKH51 (21mm×17mm×2mm) after mirror grinding, degreasing and cleaning, and set the prepared base material in the arc ion of the structure in which the base material rotates at the center surrounded by multiple targets in the plating device. For the target for a1 layer, use Al 60 Cr 37 Si 3 As the target, a vanadium target was used as the target for the a2 layer. Thereafter, as an initial step, after heating and degassing the substrate at 450° C. in the apparatus, Ar gas was introduced to perform plasma cleaning treatment (Ar ion etching) on the surface of the substrate.

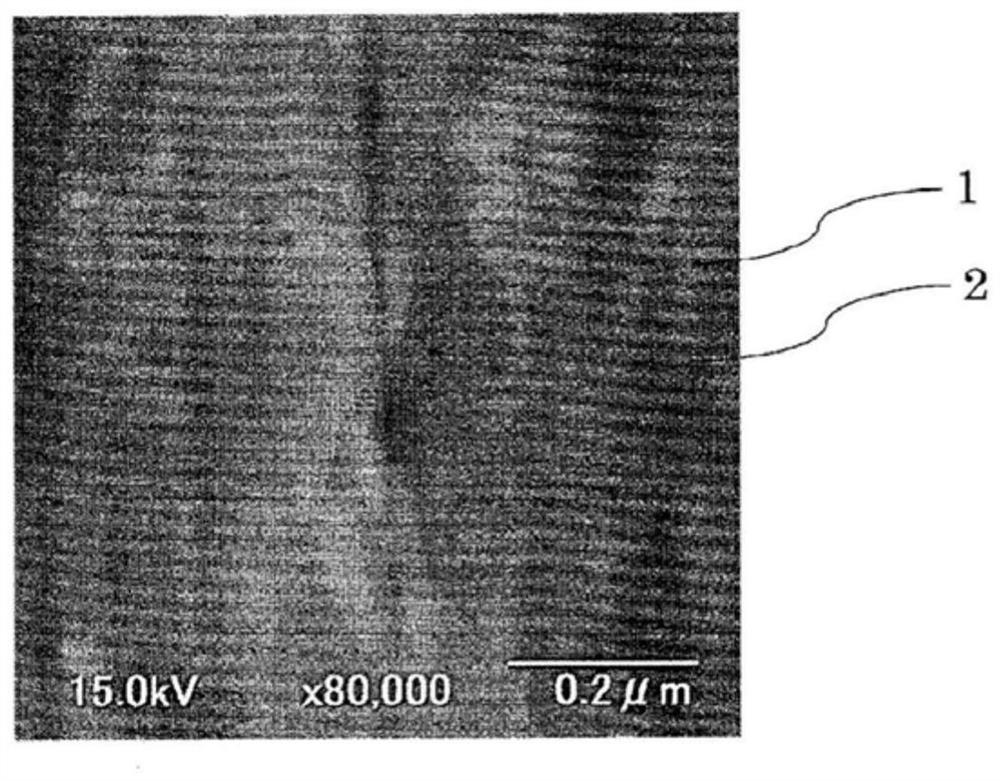

[0050] Next, the base material after the plasma cleaning treatment was coated while introducing nitrogen gas, and Sample No. 1 and Sample No. 2 were prepared. Sample No. 1 and Sample No. 2 both formed a film (alternate la...

Embodiment 2

[0053] Next, wear resistance was evaluated by simulating the middle stage of hot stamping. In addition to sample No.1 and sample No.2 of Example 1, the samples to be evaluated were further adjusted to AlCrSiN: 19nm, VN: 10nm (ta2 / ta1=0.52), and the total film of the alternate lamination part The thickness is set to 19 μm, and the other manufacturing method is the same as that of sample No. 1. Sample No. 3 and the alternate lamination of AlCrSiN and CrN that do not contain V as a comparative example (alternative lamination of AlCrSiN: 23 nm, CrN: 26 nm, total Sample No. 4 with a thickness of 4.1 μm). A ball-on-disk tester (tribometer (Tribometer) manufactured by CSM Instruments) was used in the test. As for the test environment, a pin made of matrix high speed steel (a mirror-polished hemisphere with a tip diameter of 6mm and a hardness of 64HRC) was placed under a load of 10N on one side in an atmosphere of 400°C assuming the mid-term processing of hot stamping. ) is pressed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com