Antibacterial high-strength ultrathin composite membrane material, preparation method thereof, and application of material in uranium enrichment in uranium-containing wastewater or seawater

A composite membrane, high-strength technology, applied in the field of uranium resource recovery, to achieve the effects of good biocompatibility, excellent broad-spectrum antibacterial properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of CNC-PAO composite membrane:

[0038] Dissolve 17.5 mg of PAO in 0.5 ml of NAOH solution with a concentration of 0.3 mol / L, then mix it with 50 μl of 6% sulfonated cellulose nanocrystal aqueous solution, and wait until the two are fully mixed. Add 0.2 μl of wet strength agent, and then add 0.5ml of chitosan quaternary ammonium salt solution with a concentration of 0.5% after mixing, and finally complete the preparation of the pre-liquid by fully oscillating and mixing with a vortex instrument. Glue a 1mm thick silicone rubber sheet with a 3*3cm hole to a glass sheet to form a mold, inject 200μl pre-liquid into the mold, and dry it in an oven at 65°C for 1 hour to form a spare State a film with a thickness of 10 μm.

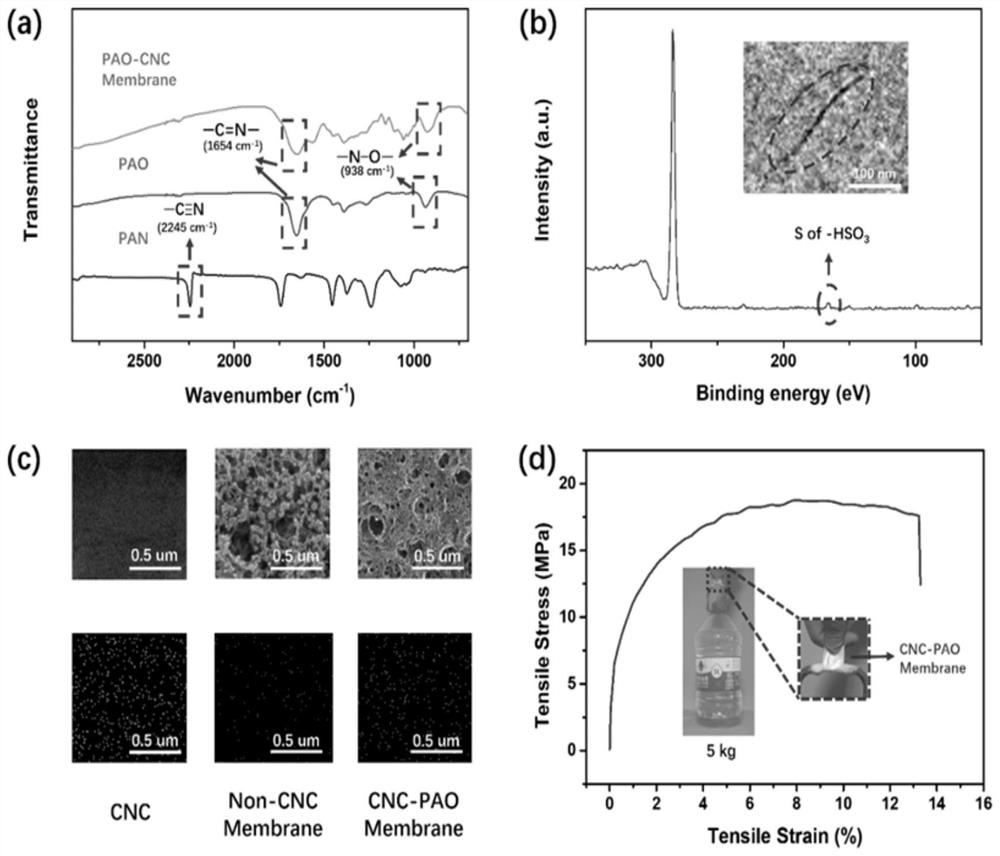

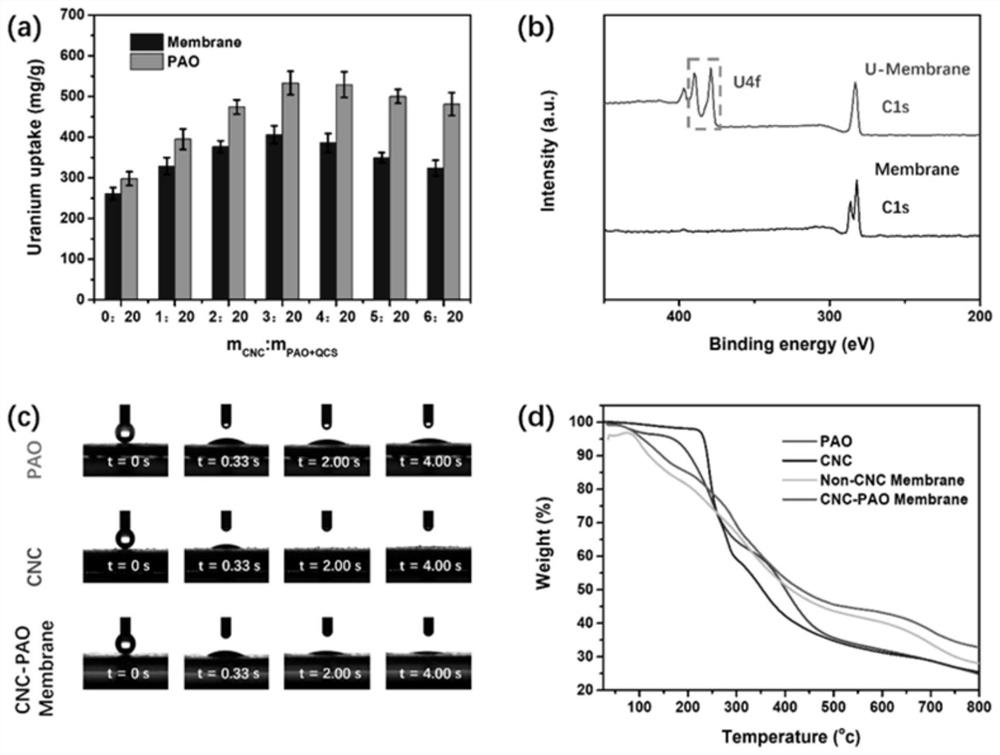

[0039] Using Fourier transform infrared spectroscopy (FT-IR) to characterize the film material samples ( figure 1 a). After the oximation reaction, the C≡N characteristic absorption peak of PAN (2245cm -1 ) disappeared, and two new charact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com