A tungsten-based material with both solid solution and dispersion strengthening and its preparation method

A dispersion-strengthening, tungsten-based technology, which is applied in the field of both solid solution and dispersion-strengthened tungsten-based materials and its preparation, can solve the problems of material performance degradation, low Zr diffusion/solution efficiency, grain boundary segregation, etc., to reduce Production cost, improvement of strengthening and toughening effects, improvement of yield and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 (W 99 Zr 1 ) 99.7 Fe 0.3 Alloy preparation

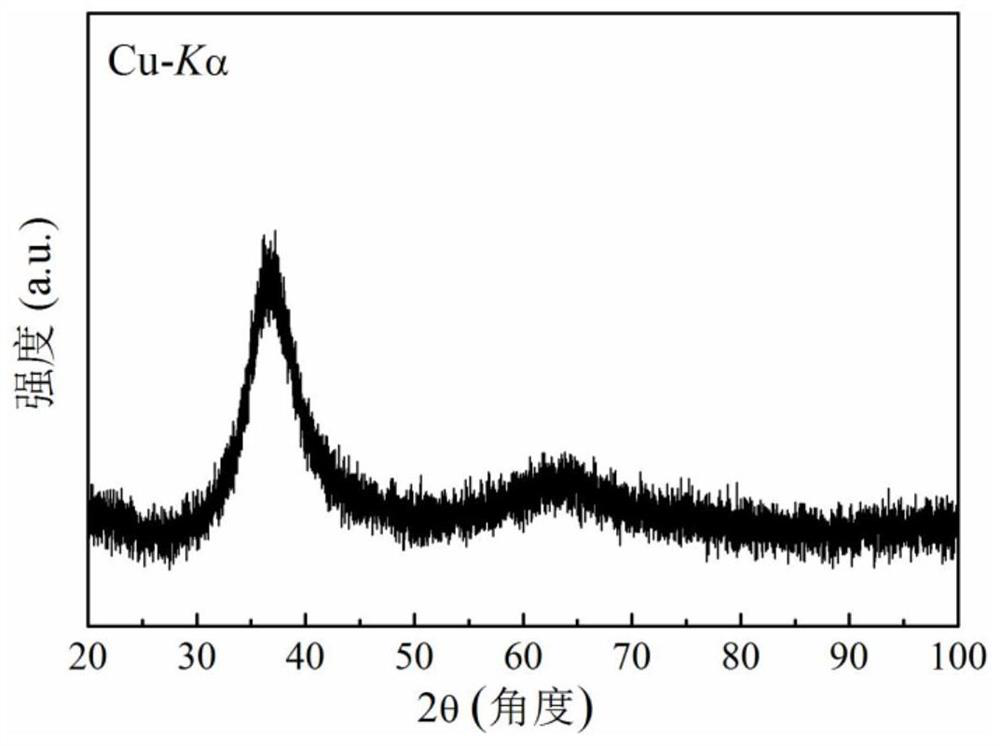

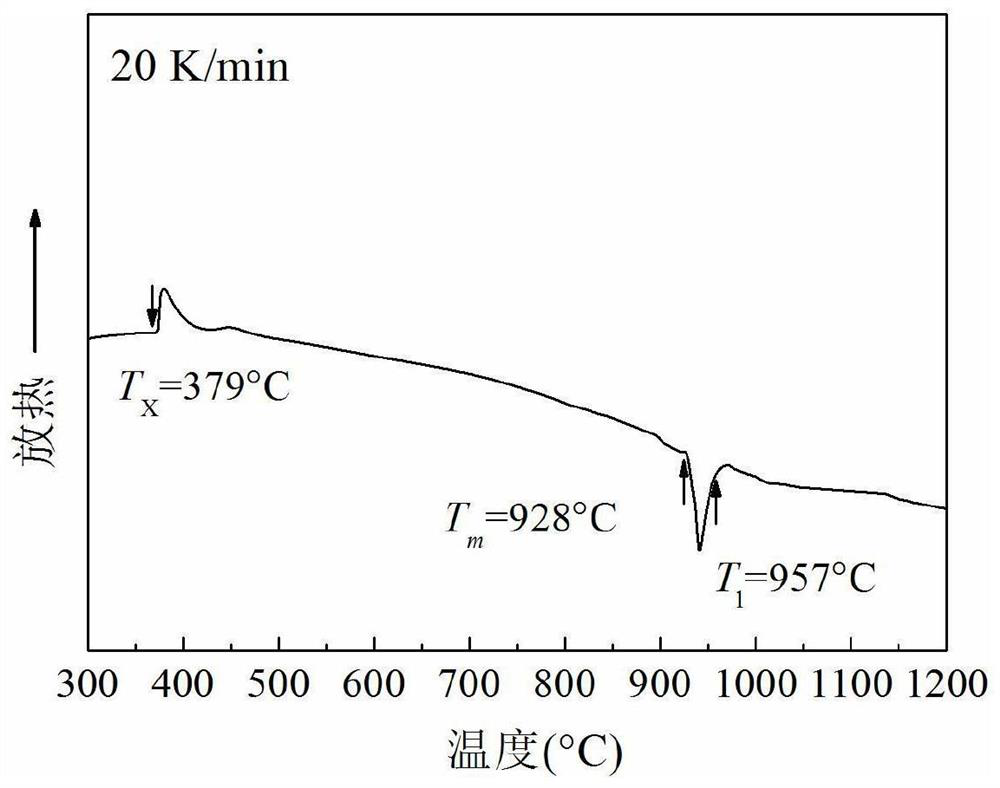

[0021] Step one, Zr 76 Fe 24 Preparation of Master Alloy Amorphous Powder

[0022] Using industrially pure Zr (>99.5%) and Fe (>99.5%) metals as raw materials, the composition of Zr by atomic percentage 76 Fe 24 Conversion, weighing, and alloy preparation; the raw materials are mixed and placed in a water-cooled copper crucible of a non-consumable arc melting furnace, and then vacuumed to about 6×10 -3 Pa, filled with 0.05MPa industrial pure Ar atmosphere for smelting, the arc melting working current is 150A; then the alloy ingot is turned upside down, so repeated smelting 4 times to obtain an alloy ingot with uniform composition. Next, crush the alloy ingot and put it into a quartz tube, place the quartz tube in an induction heating coil, and then evacuate to about 1×10 -2 Pa, filled with 0.05MPa commercially pure Ar; using copper roll single roll spin quenching technology, the alloy sample is melted an...

Embodiment 2

[0026] Embodiment 2 (W 95 Zr 5 ) 99.1 Fe 0.9 Alloy preparation

[0027] Step one, Zr 85 Fe 15 Preparation of Master Alloy Amorphous Powder

[0028] Using industrial pure Zr (>99.5%) and Fe (>99.5%) as raw materials, the composition of Zr by atomic percentage 85 Fe 15 Conversion, weighing, and alloy preparation; the raw materials are mixed and placed in a water-cooled copper crucible of a non-consumable arc melting furnace, and then vacuumed to about 6×10 -3 , filled with industrial pure Ar atmosphere of 0.1MPa for smelting, the working current of arc melting is 180A; then the alloy ingot is turned upside down, and the alloy ingot with uniform composition is obtained by repeated melting for 4 times. Next, crush the alloy ingot and put it into a quartz tube, place the quartz tube in an induction heating coil, and then evacuate to about 1×10 -2 Pa, filled with 0.1MPa commercially pure Ar; using copper roll single roll spin quenching technology, the alloy sample is melted...

Embodiment 3

[0032] Embodiment 3 (W 92 Zr 8 ) 97 Fe 3 Alloy preparation

[0033] Step one, Zr 72 Fe 28 Preparation of Master Alloy Amorphous Powder

[0034] Using industrial pure Zr (>99.5%) and Fe (>99.5%) as raw materials, the composition of Zr by atomic percentage 72 Fe 28 Conversion, weighing, and alloy preparation; the raw materials are mixed and placed in a water-cooled copper crucible of a non-consumable arc melting furnace, and then vacuumed to about 6×10 -3 , filled with industrial pure Ar atmosphere of 0.1MPa for smelting, the working current of arc smelting is 150A; then the alloy ingot is turned upside down, and smelting is repeated 4 times in this way to obtain an alloy ingot with uniform composition. Next, crush the alloy ingot and put it into a quartz tube, place the quartz tube in an induction heating coil, and then evacuate to about 1×10 -2 Pa, filled with 0.1MPa commercially pure Ar; using copper roll single roll spin quenching technology, the alloy sample is mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com