Preparation method of high-dielectric-property copper calcium titanate epitaxial film

A technology of calcium copper titanate and epitaxial thin film is applied in the field of functional material research and technology development, which can solve the problems of complex and expensive equipment process, unfavorable industrial production, etc., and achieve the effect of simple equipment, important application value and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

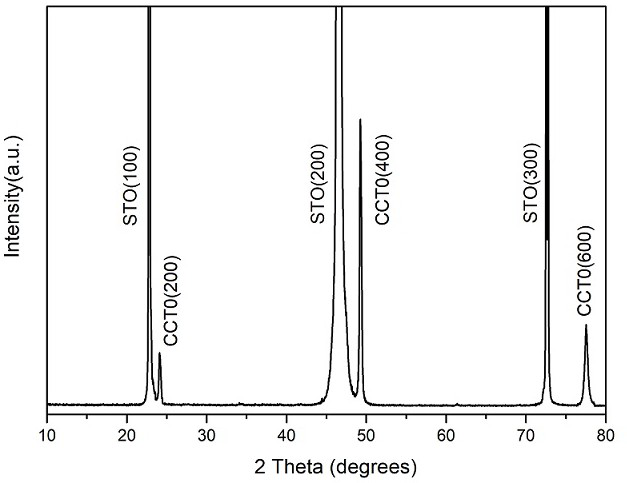

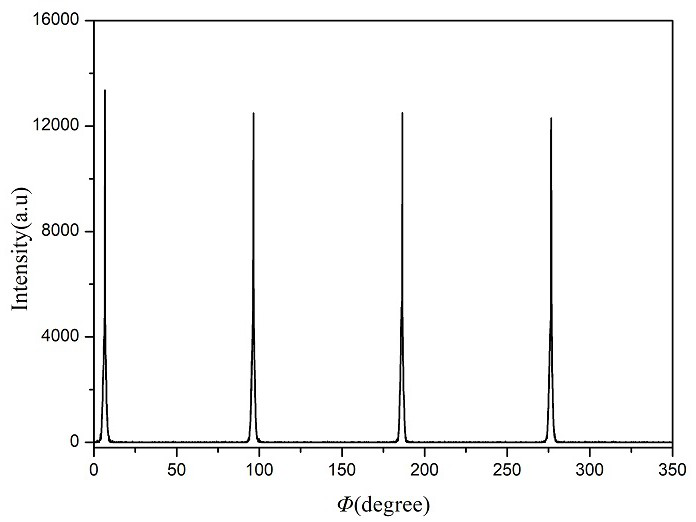

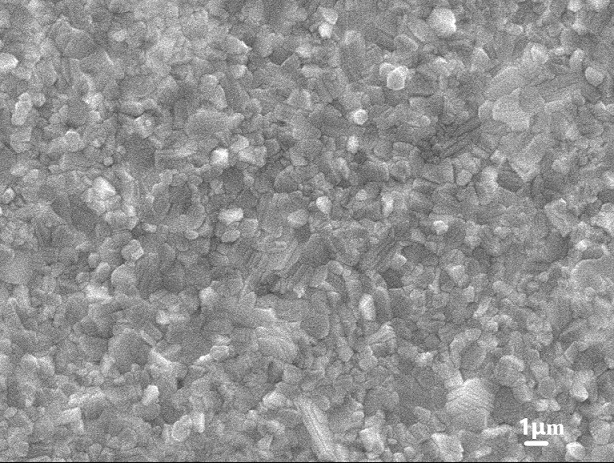

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Preparation of CCTO sol

[0035] With calcium acetate (Ca(CH) 3 COO) 2 ) as precursor, propionic acid as complexing agent, and methanol as solvent to prepare calcium acetate sol, add calcium acetate to methanol in a glove box with a humidity of less than 30%, add propionic acid dropwise, and stir for 2 hours under heating at 40°C Dissolve to obtain a clear and transparent solution A, the molar ratio of calcium acetate: propionic acid: methanol in the solution is 1:2:10;

[0036] With copper acetate (Cu(CH) 3 COO) 2 ) as precursor, propionic acid as complexing agent, and methanol as solvent to prepare copper acetate sol. In a glove box with a humidity of less than 30%, copper acetate was added to methanol, and propionic acid was added dropwise, and stirred at 40°C for 2 hours. A blue-green translucent solution B was obtained, and the molar ratio of copper acetate: propionic acid: methanol in the solution was 1:3:10;

[0037] With tetrabutyl titanate (C 16 H...

Embodiment 2

[0045] Step 1: Preparation of CCTO sol

[0046] With calcium acetate (Ca(CH) 3 COO) 2 ) as precursor, propionic acid as complexing agent, and methanol as solvent to prepare calcium acetate sol. Calcium acetate was added to methanol in a glove box with a humidity of less than 30%, and propionic acid was added dropwise, and the solution A was obtained by stirring for 2 hours under heating at 80° C. to dissolve. The molar ratio of calcium acetate: propionic acid: methanol in the solution is 1:4:40.

[0047] With copper acetate (Cu(CH) 3 COO) 2 ) as precursor, propionic acid as complexing agent, and methanol as solvent to prepare copper acetate solution. In a glove box with a humidity of less than 30%, copper acetate was added to methanol, and propionic acid was added dropwise, and stirred for 2 hours under heating at 40-90° C. to obtain a blue-green translucent solution B. The molar ratio of copper acetate: propionic acid: methanol in the solution is 1:10:40.

[0048] With...

Embodiment 3

[0055] Step 1: Preparation of CCTO sol

[0056] With calcium acetate (Ca(CH) 3 COO) 2 ) as precursor, propionic acid as complexing agent, and methanol as solvent to prepare calcium acetate sol. Calcium acetate was added to methanol in a glove box with a humidity of less than 30%, and propionic acid was added dropwise, and the solution A was obtained by stirring for 2 hours under heating at 60° C. to dissolve. The molar ratio of calcium acetate: propionic acid: methanol in the solution is 1:3:25.

[0057] With copper acetate (Cu(CH) 3 COO) 2 ) as precursor, propionic acid as complexing agent, and methanol as solvent to prepare copper acetate sol. In a glove box with a humidity of less than 30%, copper acetate was added to methanol, and propionic acid was added dropwise, and stirred for 2 hours under heating at 60° C. to obtain a blue-green translucent solution B. The molar ratio of copper acetate: propionic acid: methanol in the solution is 1:6.5:25.

[0058] With tetrab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com