Two-section type absorption water chilling unit directly using blast furnace slag flushing water as heat source

A blast furnace slag flushing water and chiller technology, which is applied to boiler absorbers, machines using waste heat, refrigerators, etc., can solve the problems of unable to reduce slag flushing water, low utilization rate of waste heat, and high total hardness, so as to avoid the settlement of particles The effects of hardening, improving the utilization rate of waste heat, and enhancing the degree of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

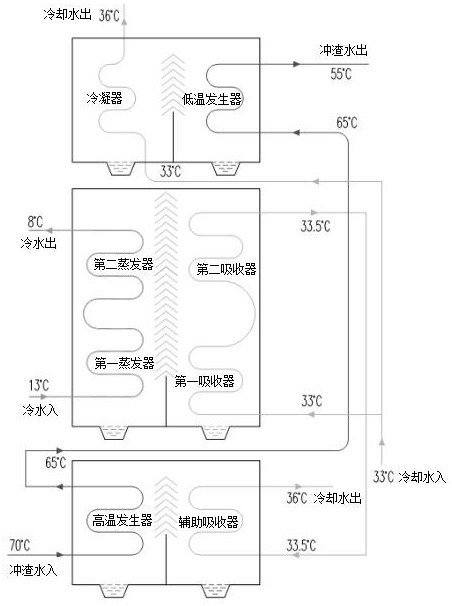

[0028] Such as figure 1 Shown: a two-stage chiller with blast furnace slag flushing water as the heat source, including a unit body, the unit body includes a high-temperature generator and a low-temperature generator; the high-temperature generator is connected to the low-temperature generator in sequence, and the The inlet of the high temperature generator is connected to the slag washing water inlet pipeline, and the outlet of the low temperature generator is connected to the slag washing water outlet pipeline.

[0029] The above scheme has the following advantages: the inlet water requirement for the heat source of the two-stage hot water lithium bromide absorption chiller under standard working conditions is 70°C or above. can be lowered. Therefore, even if the slag flushing process is unstable, the temperature of the slag flush...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com