Slag-adhesion-preventing refractory castable for molten iron composite slagging-off plate, and preparation method and use method of slag-adhesion-preventing refractory castable

A technology of refractory castable and slag scraping plate, which is applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

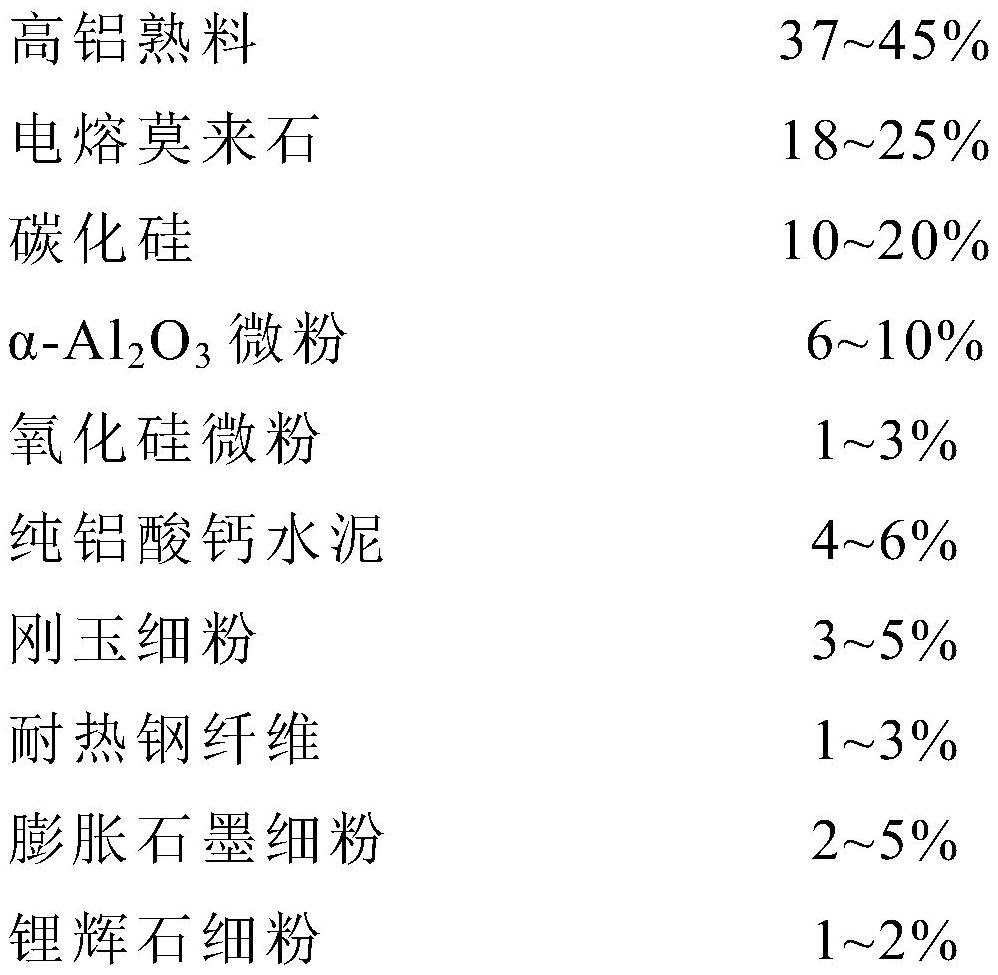

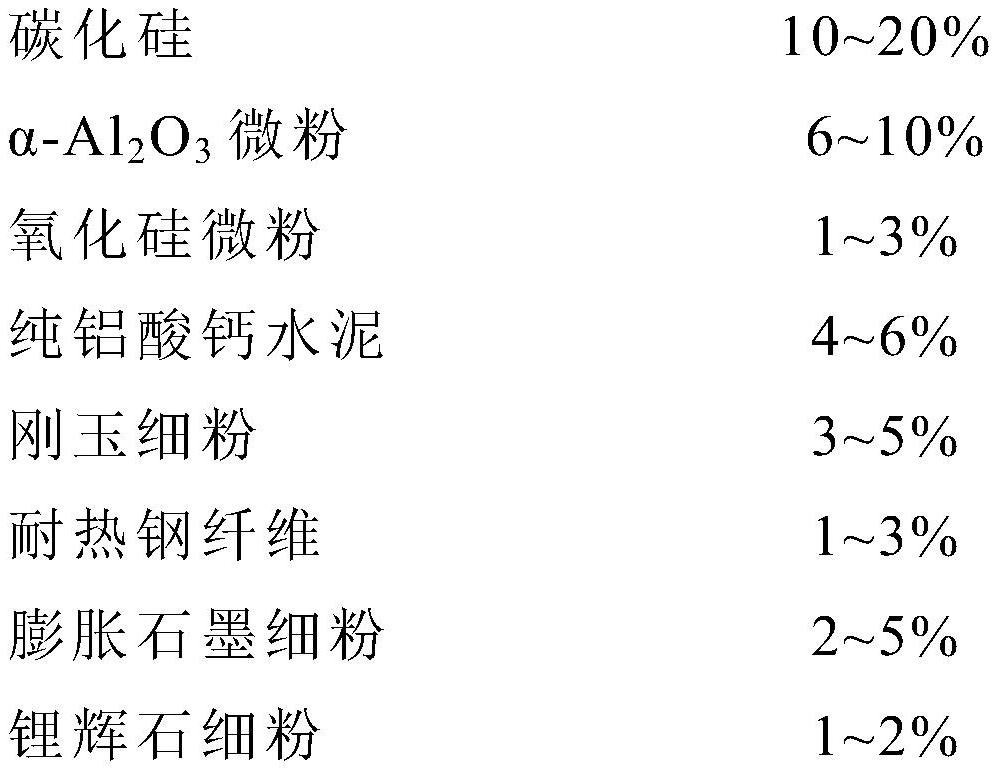

[0034] The anti-sticking slag refractory castable for molten iron composite slag removal board includes main raw materials and auxiliary raw materials. The main raw materials include: high-alumina clinker 37% (among them, the weight of high-alumina clinker with a particle size of 8-5mm accounts for the total weight of main raw materials 18% of high-alumina clinker with a particle size of 5-3mm accounts for 19% of the total weight of the main raw materials), and 25% of fused mullite (wherein the weight of fused mullite with a particle size of 3-1mm accounts for 19% of the total weight of the main raw materials) 15% of the total weight, the weight of fused mullite with a particle size of 1-0.088mm accounts for 10% of the total weight of the main raw materials), and 10% of silicon carbide (wherein the weight of silicon carbide with a particle size of 1-0.088mm accounts for the total weight of the main raw materials 5% of the weight, the particle size is 325 mesh silicon carbide we...

Embodiment 2

[0038] The anti-sticking slag refractory castable for molten iron composite slag removal board includes main raw materials and auxiliary raw materials. The main raw materials include: 40% of high-alumina clinker (the weight of high-alumina clinker with a particle size of 8-5mm accounts for the total weight of main raw materials) 20% of the high-alumina clinker with a particle size of 5-3mm accounts for 20% of the total weight of the main raw materials), 20% of fused mullite (wherein the weight of fused mullite with a particle size of 3-1mm accounts for 20% of the main raw material 13% of the total weight, fused mullite with a particle size of 1-0.088mm accounts for 7% of the total weight of the main raw materials), silicon carbide 13% (wherein, the weight of silicon carbide with a particle size of 1-0.088mm accounts for the total weight of the main raw materials 7% of the weight, the particle size is 325 mesh silicon carbide weight accounts for 6% of the total weight of the mai...

Embodiment 3

[0042] The anti-sticking slag refractory castable for molten iron composite slag removal board includes main raw materials and auxiliary raw materials, and the main raw materials include: 45% of high-alumina clinker by weight percentage (wherein, the weight of high-alumina clinker with a particle size of 8-5mm accounts for the total weight of main raw materials 22% of high-alumina clinker with a particle size of 5-3mm accounts for 23% of the total weight of the main raw materials), and 18% of fused mullite (among them, fused mullite with a particle size of 3-1mm accounts for 23% of the total weight of the main raw materials 11% of the total weight, fused mullite with a particle size of 1-0.088mm accounts for 7% of the total weight of the main raw materials), silicon carbide 13% (wherein, the weight of silicon carbide with a particle size of 1-0.088mm accounts for the total weight of the main raw materials 7% of the weight, the particle size is 325 mesh silicon carbide weight ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com