High-carbon cold-rolled steel sheet, method for producing same, and high-carbon steel machine component

A technology of cold-rolled steel plate and manufacturing method, applied in the field of high-carbon cold-rolled steel plate, to achieve the effects of excellent wear resistance, excellent impact properties, and excellent fatigue resistance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

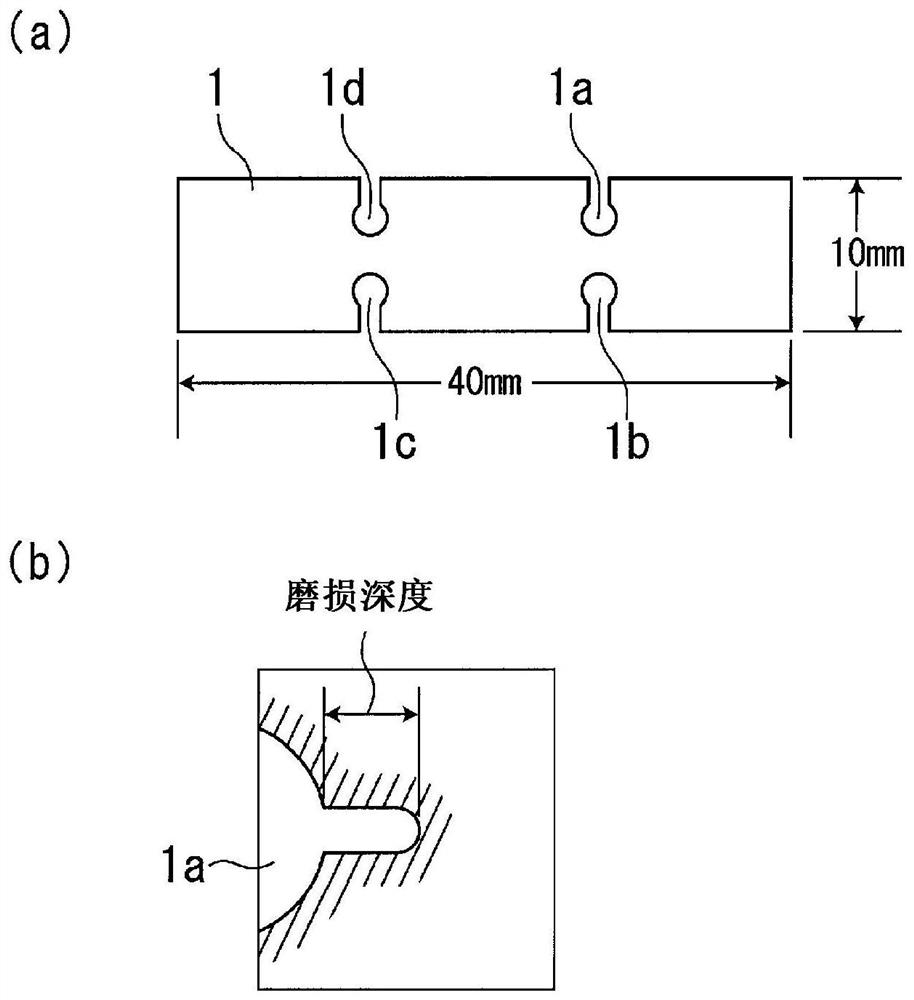

[0113] Molten steel having the chemical composition shown in Table 1 was melted in a vacuum melting furnace, and cast into a mold to produce a small steel block (50 kgf). These small ingots were billet-rolled to form steel sheets, and then hot-rolled at a heating temperature of 1150° C. and a finishing temperature of 870° C. to form hot-rolled steel sheets (thickness: 4 mm). Next, the obtained hot-rolled steel sheets were subjected to cold rolling and spheroidizing annealing under the conditions shown in Table 2 to produce cold-rolled steel sheets with a thickness of 0.4 mm to less than 1.0 mm.

[0114] First, a test piece for structure observation was cut out from the obtained cold-rolled steel sheet, embedded in resin, polished and etched, and the structure was observed and photographed with a secondary electron image of a scanning electron microscope (magnification: 2000 times). Analyze and calculate the average particle size of carbides (d av ) and spheroidization rate (N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

| Shock value | aaaaa | aaaaa |

| Wear depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com