A kind of porous ceramics for air bearing and its preparation method and application

A technology of porous ceramics and composite ceramics, applied in the field of porous ceramic materials, can solve the problems of low hardness of porous stainless steel, reduce the permeability of porous materials, affect the performance of air bearings, etc., achieve high porosity and reduce the amount of grinding debris , excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

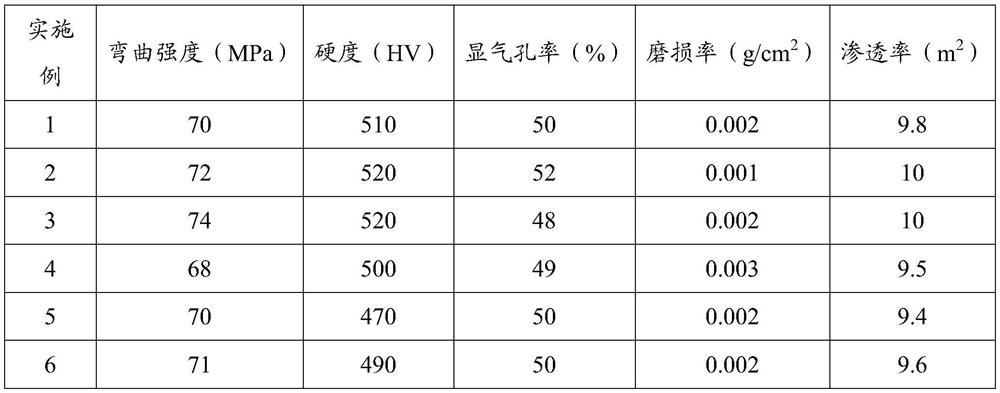

Examples

Embodiment 1

[0025] A preparation method of porous ceramics, the method comprising the steps of:

[0026] In parts by weight, prepare 60 parts of alumina composite ceramic powder, 45 parts of binder and 5 parts of pore-forming agent. The median particle size of the alumina composite ceramic powder is 3-12 μm. The median particle size of the binder is 1-2 μm, and the median particle size of the pore-forming agent is 10-30 μm. Wherein the alumina composite ceramic powder comprises 80% alumina, 15% zirconia, 3% silicon carbide and 2% silica by weight percentage, and the binder comprises a mass ratio of 3.2: 0.8:0.3 of alumina, magnesia and titania, and the pore-forming agent is ammonium bicarbonate.

[0027] The above powder is ball-milled according to the mass ratio of material: ball: medium absolute ethanol as 1.5:1:1.5, the ball mill used is a planetary ball mill, and the ball milling speed is 200r / min. Then, the ball-milled slurry is taken out and dispersed in an ethanol solvent with a ...

Embodiment 2

[0031] A preparation method of porous ceramics, the method comprising the steps of:

[0032] In parts by weight, prepare 70 parts of alumina composite ceramic powder, 40 parts of binder and 8 parts of pore-forming agent, the median particle size of the alumina composite ceramic powder is 3-12 μm, and the The median particle size of the binder is 1-2 μm, and the median particle size of the pore-forming agent is 10-30 μm. Wherein, the alumina composite ceramic powder comprises 90% alumina, 5% zirconia, 4% silicon carbide and 1% silica by weight percentage, and the binder comprises a mass ratio of 3.5: 0.5:0.5 of alumina, magnesia and titania, and the pore-forming agent is polystyrene microspheres.

[0033] The above powder is ball-milled according to the mass ratio of material: ball: medium deionized water as 1.2:1:2.5, the ball mill used is a planetary ball mill, and the ball milling speed is 230r / min. Then, the ball-milled slurry is taken out and dispersed in methanol solven...

Embodiment 3

[0037] A preparation method of porous ceramics, the method comprising the steps of:

[0038] In parts by weight, prepare 80 parts of alumina composite ceramic powder, 55 parts of binder and 10 parts of pore-forming agent, the median particle size of the alumina composite ceramic powder is 3-12 μm, and the The median particle size of the binder is 1-2 μm, and the median particle size of the pore-forming agent is 10-30 μm. Wherein, the alumina composite ceramic powder includes 75% alumina, 20% zirconia, 3% silicon carbide and 2% silica by weight percentage, and the binder includes a mass ratio of 3.5: 0.5:0.3 of alumina, magnesia and titania, the pore-forming agent is a mixture of graphite powder and carbon powder in a weight ratio of 1:1.

[0039] The above powder is ball-milled according to the mass ratio of material: ball: medium acetone of 1.5: 1: 2, the ball mill used is a planetary ball mill, and the ball milling speed is 250 r / min. Then, the ball-milled slurry is taken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com