Ultrasonic vibration assisted laser welding method for heterogeneous material

A laser welding and ultrasonic vibration technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of uneven elements, and achieve the effect of eliminating brittle phase, increasing absolute temperature, and inhibiting segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

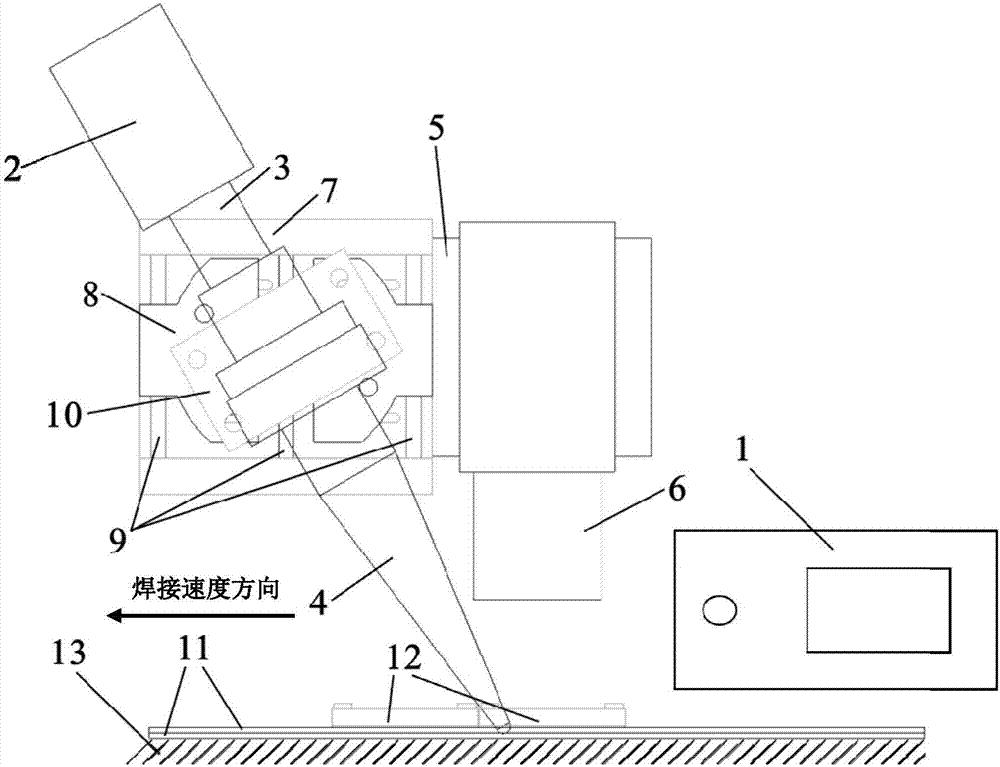

[0024] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

[0025] A. Place the Hastelloy C-276 plate with a thickness of 0.5mm on top of the austenitic stainless steel 304 plate with a thickness of 2.0mm, use copper clamps to clamp and fix the heterogeneous materials, and fix the fixture to the machine tool On the stage, the welding form is lap welding, and the distance between the welding clamps is selected as 10mm.

[0026] B. The ultrasonic generator generates ultrasonic high-frequency alternating current, which is converted into ultrasonic mechanical vibration through the transducer. After multi-stage horn amplification, the ultrasonic wave is guided into the welding pool by the tip of the ultrasonic tool head. The ultrasonic vibration frequency is selected as 20 kHz, the power of the ultrasonic generator is 1.4 kW, and the corresponding amplitude of the tip of the tool hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com