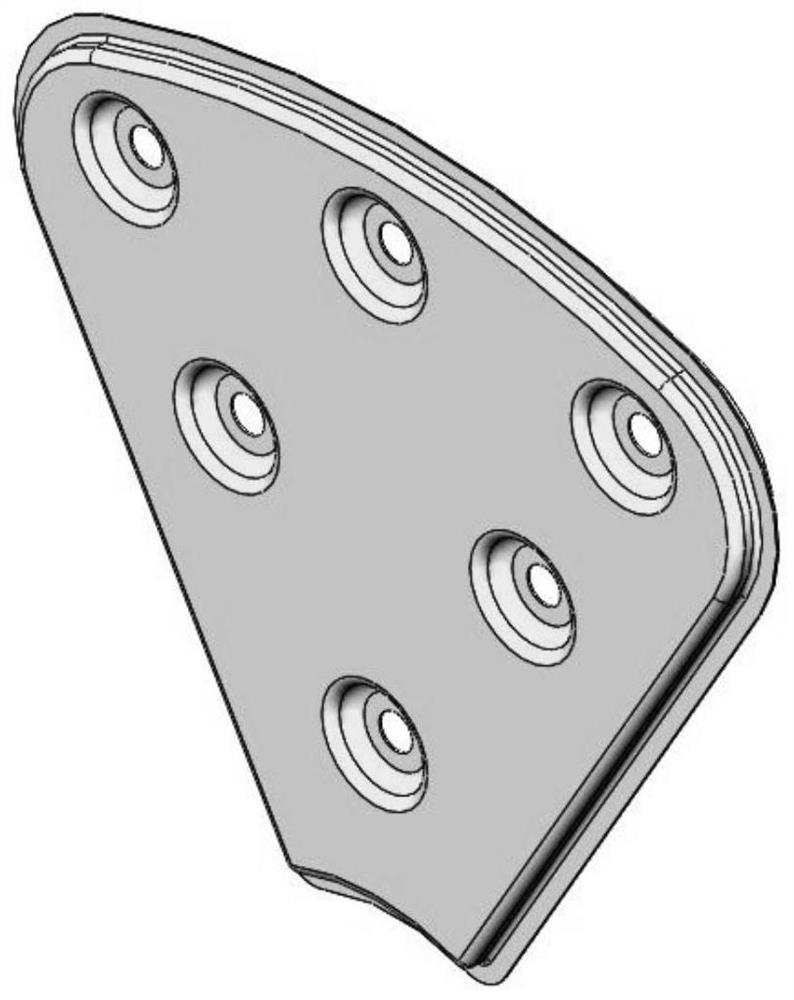

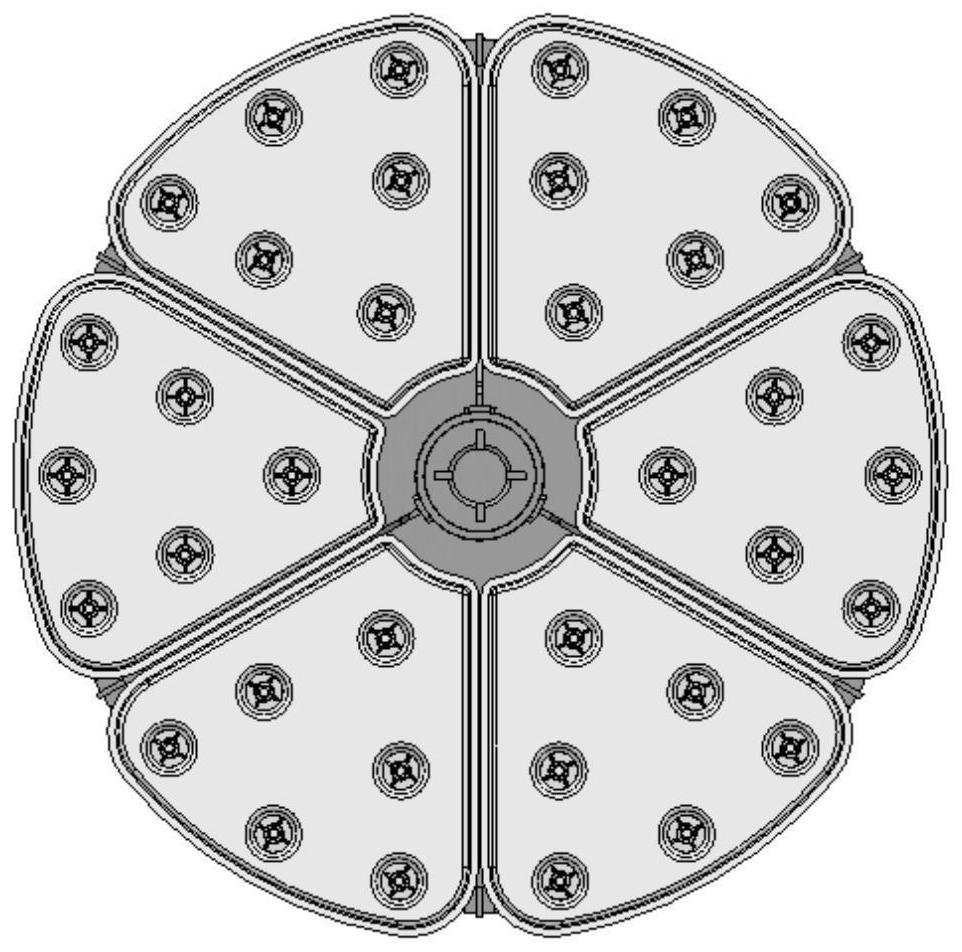

Double-component PVDC latex for biological rotating disc

A biological turntable and two-component technology, applied in sustainable biological treatment, biological water/sewage treatment, single-component halogenated hydrocarbon artificial filament, etc., can solve unfavorable film formation, unfavorable microbial film formation, large dosage, etc. problems, to achieve the effect of stable structure, reduced impact, and high amount of film hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0044] Preparation of component A:

[0045] The raw materials of component A are as follows: 40 parts of vinylidene chloride, 4 parts of methoxypolyethylene glycol acrylate, 4 parts of methyl methacrylate, 4 parts of glycidyl methacrylate, 50 parts of deionized water, 0.1 parts The compound of SAS and 0.1 part of OP-1 was used as emulsifier, and the compound of 0.04 part of potassium persulfate and 0.02 part of sodium bisulfite was used as initiator.

[0046] (A1) Disperse 10wt% initiator, 5wt% mixed monomer and water, heat up to 50°C, and react at a speed of 300rpm for 2h to obtain a seed emulsion;

[0047] (A2) Slowly add emulsifier, remaining mixed monomers and initiator to the seed emulsion obtained in step (A1), after adding 2 hours, continue to heat up to 65°C, react for 3 hours, cool, and discharge to obtain component A emulsion. Solid content 51.3%;

[0048] Preparation of component B:

[0049] The raw materials of component B are as follows: 40 parts of vinylidene ...

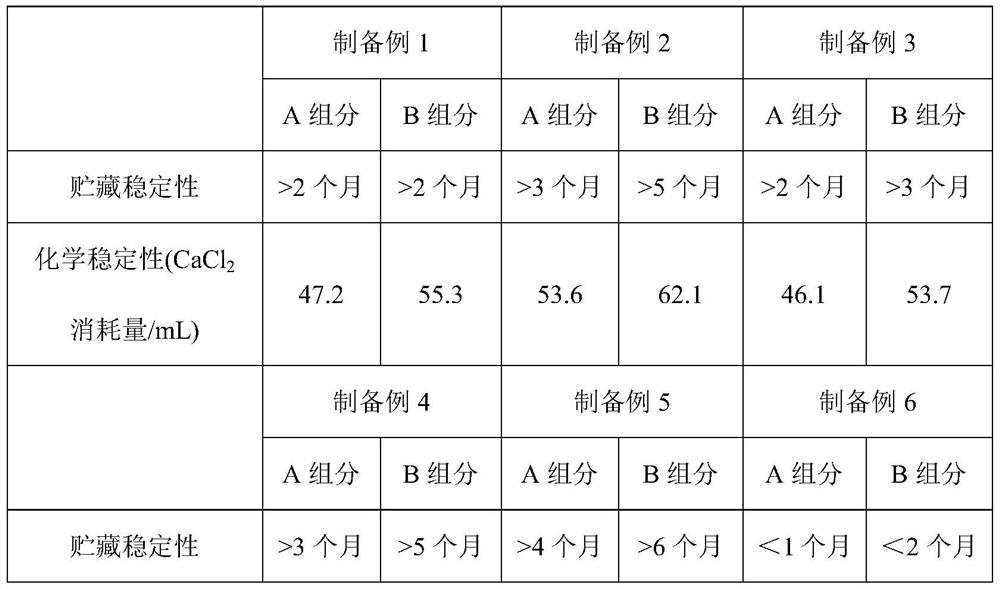

preparation example 2

[0053] Other conditions and steps are the same as in Preparation Example 1, except that 4 parts of methyl methacrylate in components A and B are replaced by a composite of 2 parts of methyl methacrylate and 2 parts of butyl methacrylate. The solid content of the emulsion of component A is 51.0%, and the solid content of the emulsion of component B is 49.7%.

preparation example 3

[0055] Other conditions and steps are the same as in Preparation Example 1, except that 4 parts of acrylic acid in component B are replaced by 3 parts of acrylic acid and 1 part of maleic acid. The solid content of the emulsion of component A is 51.2%, and the solid content of the emulsion of component B is 49.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com