Coated lithium nickel cobalt manganese oxide positive electrode material, preparation method thereof and lithium ion battery

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the direction of battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve problems such as structural damage, cycle performance degradation, particle cracking, etc., and achieve the removal of surface residual alkali, inclusion The effect of uniform coating and stable material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a coated nickel-cobalt lithium manganese oxide positive electrode material, which is prepared according to the following steps:

[0030] (1) Spherical nickel-cobalt-manganese hydroxide and Li 2 CO 3 According to Li: the molar ratio of nickel-cobalt-manganese hydroxide is 1.03: 1 ratio and mixes uniformly in the blender, and the molecular formula of nickel-cobalt-manganese hydroxide in the present embodiment is Ni 0.6 co 0.2 mn 0.2 (OH) 2 , the uniformly mixed material was put into a sagger, calcined at 900°C for 12h under an oxygen atmosphere, and after natural cooling, it was pulverized and sieved to obtain uncoated nickel-cobalt lithium manganese oxide NCM622.

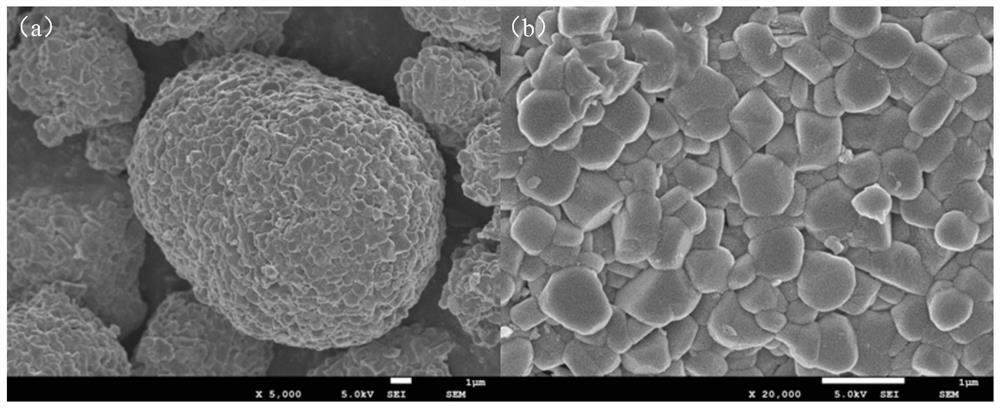

[0031] (2) Add the prepared uncoated nickel-cobalt lithium manganese oxide NCM622 into the ammonia-ammonium chloride buffer solution with pH=8.0 while stirring, and then add 1mol / L NaAlO 2 In the aqueous solution, stir and react for 1 hour, and the reacted solution is filtered thr...

Embodiment 2

[0035] This embodiment provides a coated nickel-cobalt lithium manganese oxide positive electrode material, which is prepared according to the following steps:

[0036] (1) Spherical nickel-cobalt-manganese hydroxide and Li 2 CO 3 According to Li: the molar ratio of nickel-cobalt-manganese hydroxide is 1.03: 1 ratio and mixes uniformly in the blender, and the molecular formula of nickel-cobalt-manganese hydroxide in the present embodiment is Ni 0.6 co 0.2 mn 0.2 (OH) 2 , the uniformly mixed material was put into a sagger, calcined at 900°C for 12h under an oxygen atmosphere, and after natural cooling, it was pulverized and sieved to obtain uncoated nickel-cobalt lithium manganese oxide NCM622.

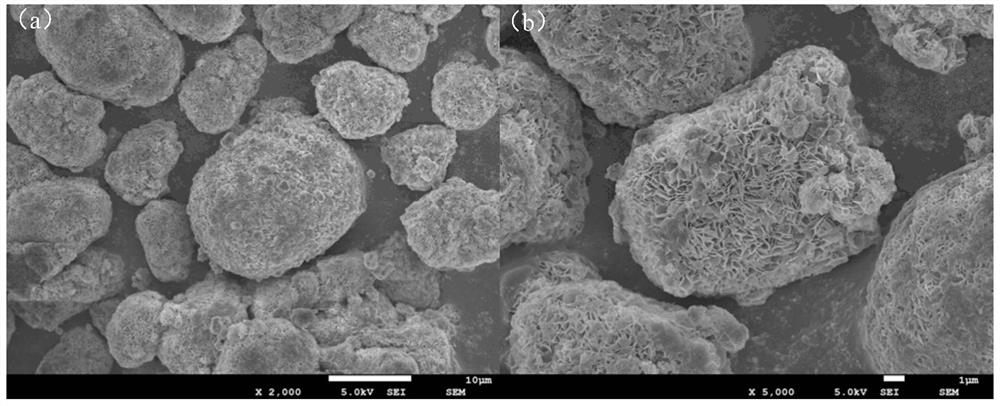

[0037] (2) Add the prepared uncoated nickel-cobalt lithium manganese oxide NCM622 into the ammonia-ammonium chloride buffer solution with pH=9.0 while stirring, and then add 1mol / L NaAlO 2 In the aqueous solution, stir and react for 1 hour, and the reacted solution is filtered thr...

Embodiment 3

[0040] This embodiment provides a coated nickel-cobalt lithium manganese oxide positive electrode material, which is prepared according to the following steps:

[0041] (1) Spherical nickel-cobalt-manganese hydroxide and Li 2 CO 3 According to Li: the molar ratio of nickel-cobalt-manganese hydroxide is 1.04: 1 ratio and is mixed in the blender evenly, and the molecular formula of nickel-cobalt-manganese hydroxide in the present embodiment is Ni 0.8 co 0.1 mn 0.1 (OH) 2 , the uniformly mixed material was put into a sagger, calcined at 850°C for 12h under an oxygen atmosphere, and after natural cooling, it was pulverized and sieved to obtain uncoated nickel cobalt lithium manganese oxide NCM811.

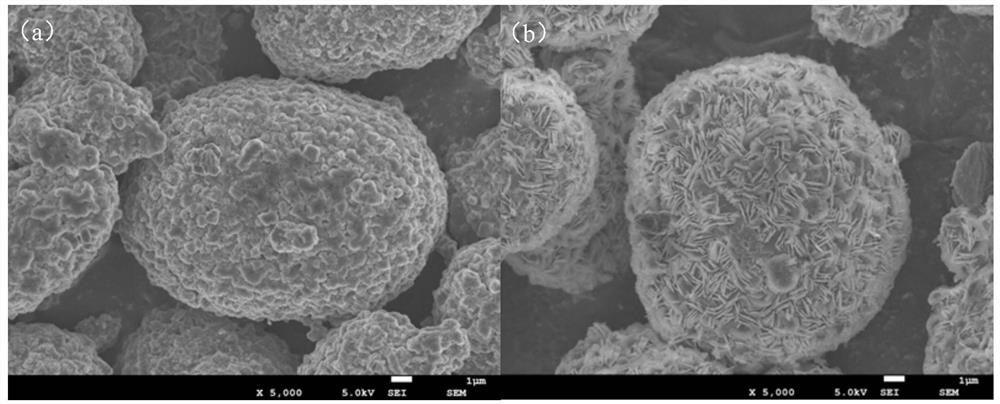

[0042] (2) Add the prepared uncoated nickel-cobalt lithium manganese oxide NCM811 into the ammonia-ammonium chloride buffer solution with pH=9.0 while stirring, and then add 1mol / L NaAlO 2 In the aqueous solution, stir and react for 1 hour, and the reacted solution is filtered thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com