Nickel-cobalt hollow composite particle as well as preparation method and application thereof

A composite particle, nickel-cobalt technology, applied in the field of wave absorbing materials, can solve the problems of unsuitable engineering application, unable to prepare metal hollow core-shell structure, low absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

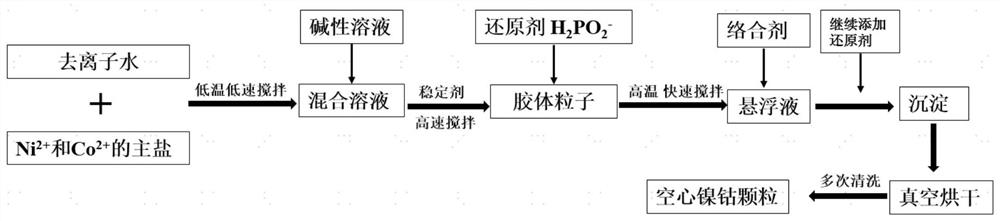

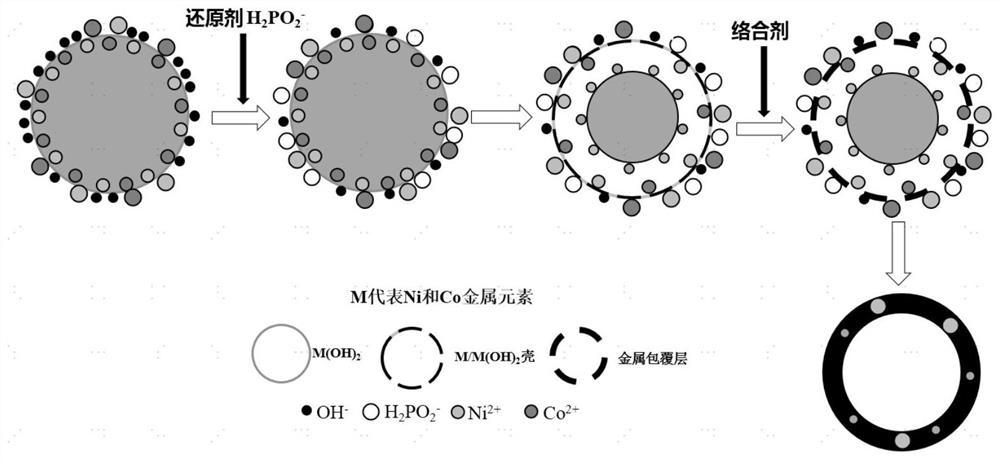

[0026] In view of the problems in the prior art that the density of wave-absorbing materials is high or the preparation method is not suitable for industrialization, this application provides a preparation method of nickel-cobalt hollow composite particles, the specific process is as follows figure 1 As shown, the nickel-cobalt hollow composite particles prepared by this method have low density, high magnetic permeability, high magnetic saturation strength, good dispersion, high specific surface area, high surface activity, and strong surface permeability due to their special structure. Good stability, as a wave-absorbing material, it has the advantages of high absorption effect, wide frequency band and superparamagnetism. Specifically, the preparation method of nickel-cobalt hollow composite particles described in the present application includes the following steps:

[0027] A) mixing nickel salt, cobalt salt and water to obtain a mixed solution; mixing the mixed solution wi...

Embodiment 1

[0041] 40 parts containing Ni 2+ and Co 2+ The main salt (nickel sulfate and cobalt sulfate) was added to 800 parts of deionized water, and stirred evenly at a low speed of 80r / min for 5min in a water bath at 50°C, wherein Ni 2+ :Co 2+ The molar ratio is 1:4; add 10 parts of alkali solution of sodium hydroxide with a concentration of 1mol / L to the mixed solution and stir rapidly at a speed of 1000r / min for 20min to form colloidal particles, then add 2 parts of stabilizer to prevent colloidal Decompose and stir slowly for 5 minutes to complete the preparation of the colloidal solution;

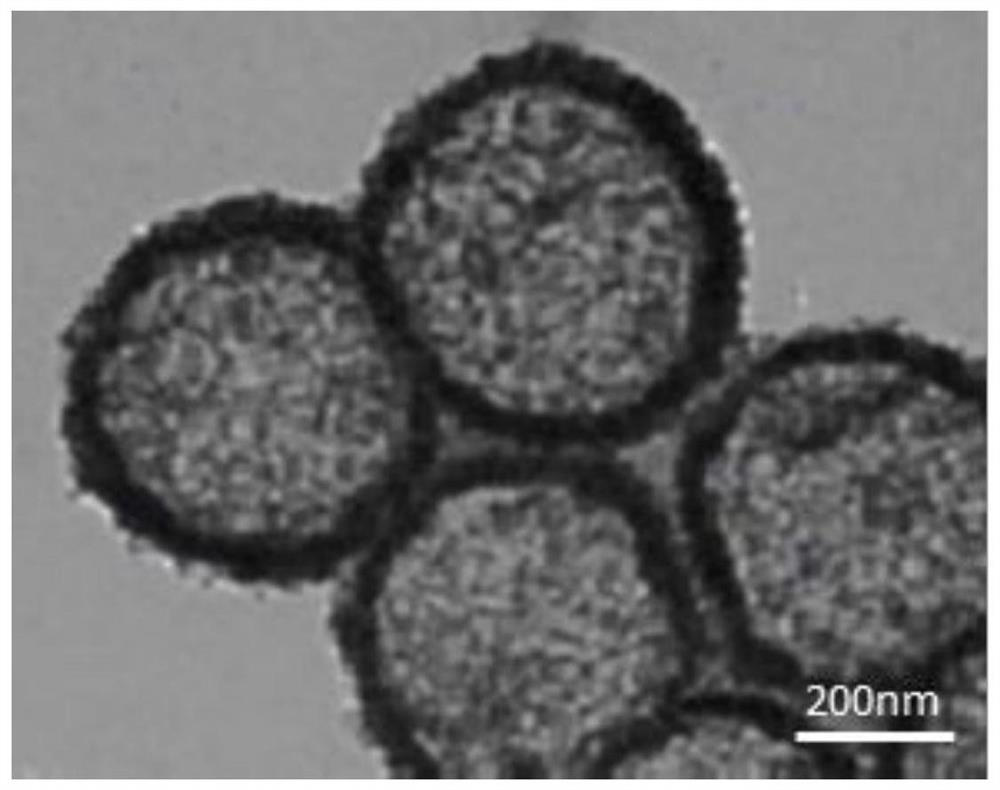

[0042] Add 6 parts of reducing agent sodium hypophosphite to the colloidal solution and stir rapidly in a water bath at 80°C at a speed of 600r / min until bubbles appear, and the reaction starts. After 6 minutes of the reaction, add 15 parts of hypophosphite to the reaction system Mixing agent disodium ethylenediaminetetraacetic acid (EDTA), so that the complexing agent can be mixed with Co(O...

Embodiment 2

[0045] 50 parts containing Ni 2+ and Co 2+ The main salt (nickel sulfate and cobalt sulfate) was added to 600 parts of deionized water, and stirred evenly at a low speed of 80r / min for 5min in a water bath at 50°C, wherein Ni 2+ :Co 2+ The molar ratio is 1:2; 20 parts of alkali solution of sodium hydroxide with a concentration of 1.5mol / L is added to the mixed solution and stirred rapidly at a speed of 1000r / min for 25min to form colloidal particles, and then 4 parts of stabilizer are added to prevent The colloid was decomposed and stirred slowly for 8 minutes to complete the preparation of the colloidal solution;

[0046] Add 10 parts of reducing agent sodium hypophosphite to the colloidal solution, stir rapidly in a water bath at 80°C at a speed of 800r / min until bubbles appear, and the reaction starts. After 8 minutes after the reaction starts, add 20 parts of hypophosphite to the reaction system. Mixing agent disodium ethylenediaminetetraacetic acid (EDTA), so that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com