Full-biphenyl polyaryletherketone precursor as well as preparation method and application thereof

A technology of polyaryletherketone and all-biphenyl type, which is applied in the field of all-biphenyl type polyaryletherketone precursor and its preparation, can solve the problems of high melting point and high molecular weight, increase the molecular weight of the polymer, and reduce the energy consumption of polymerization , Reduce the effect of side effects and gel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

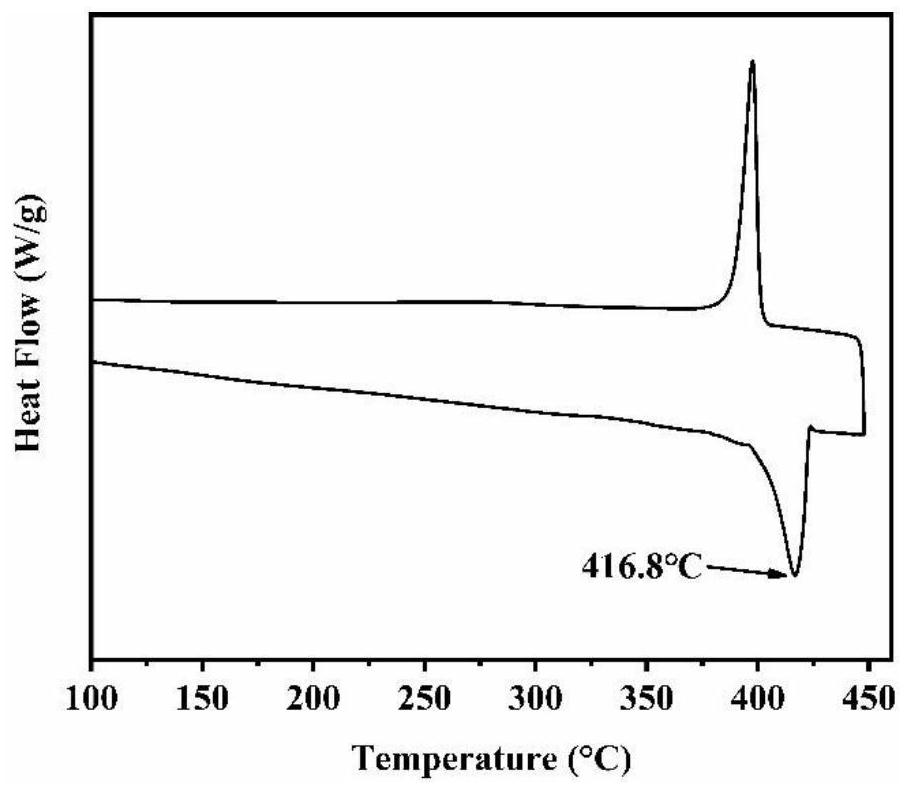

[0036] Under the protection of a nitrogen atmosphere, 4248g sulfolane (solid content 10wt%), 1010mL toluene, 207g potassium carbonate, 286g difluoromonomer 1 and 186g biphenyldiphenol were successively added to the polymerization reaction system, the temperature was raised to 140°C, and azeotropic removal Water, reflux for 2 hours, remove toluene in the reaction system by distillation, heat up to 190-210°C for 6 hours, pour the reaction product into anhydrous methanol to wash, grind and dry to obtain the precursor, and then dissolve the precursor in 4320mL In THF, after the precursor is completely dissolved, add 540mL of hydrochloric acid solution with pH=0.1 to the solution, reflux for 24h, then wash with ethanol and water and dry to obtain crystalline all-biphenyl type polyether ether ketone (PEDEK), The intrinsic viscosity of PEDEK is 2.09dL / g, T m It is 416.8°C.

Embodiment 2

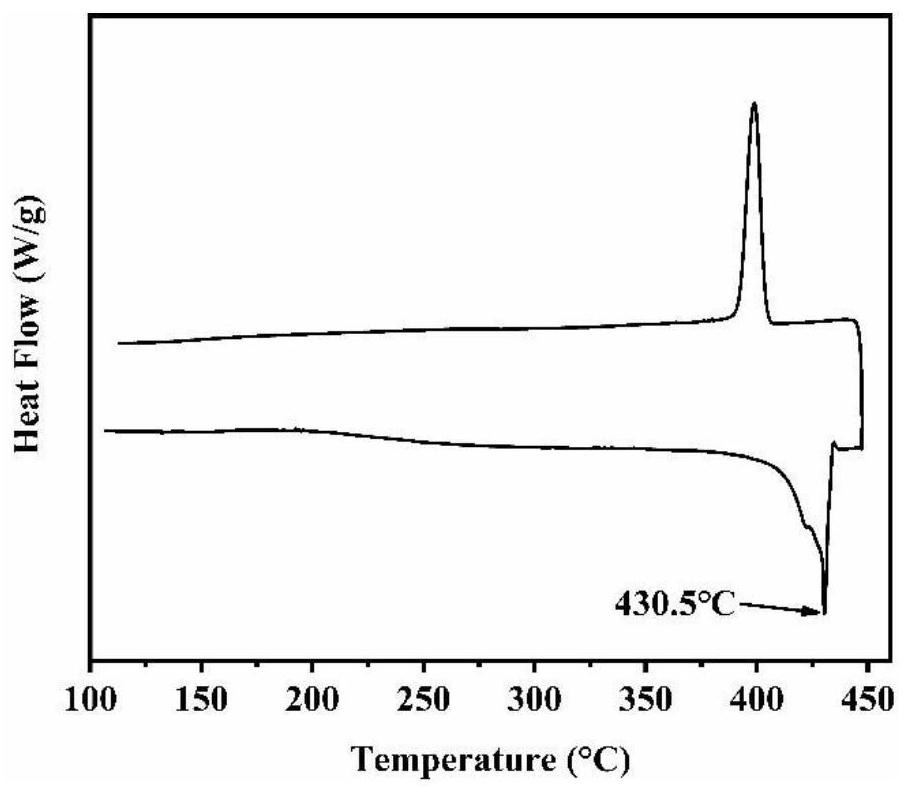

[0038] Under the protection of nitrogen atmosphere, 976g diphenyl sulfone (solid content 30wt%), 419mL xylene, 158.8g sodium carbonate, 294g difluoromonomer 2 and 204.6g biphenol were added successively to the polymerization reaction system, and the temperature was raised to 180 °C, azeotropically remove water, reflux for 2 hours, remove xylene in the reaction system by distillation, heat up to 180-210 °C for 2 hours, pour the reaction product into anhydrous methanol to wash, crush and dry to obtain the precursor, and then Dissolve the precursor in 4586ml of chloroform. After the precursor is dissolved, add 179g of dimethyl sulfoxide and 211g of 2-iodo-2-methylpropane in sequence. After reacting at 70°C for 48h, pour the reaction product into an anhydrous in methanol, then washed with anhydrous methanol and dried to obtain crystalline all-biphenyl type polyether ether ketone (PEDEK), the intrinsic viscosity of PEDEK is 2.09dL / g, T m It is 416.8°C.

Embodiment 3

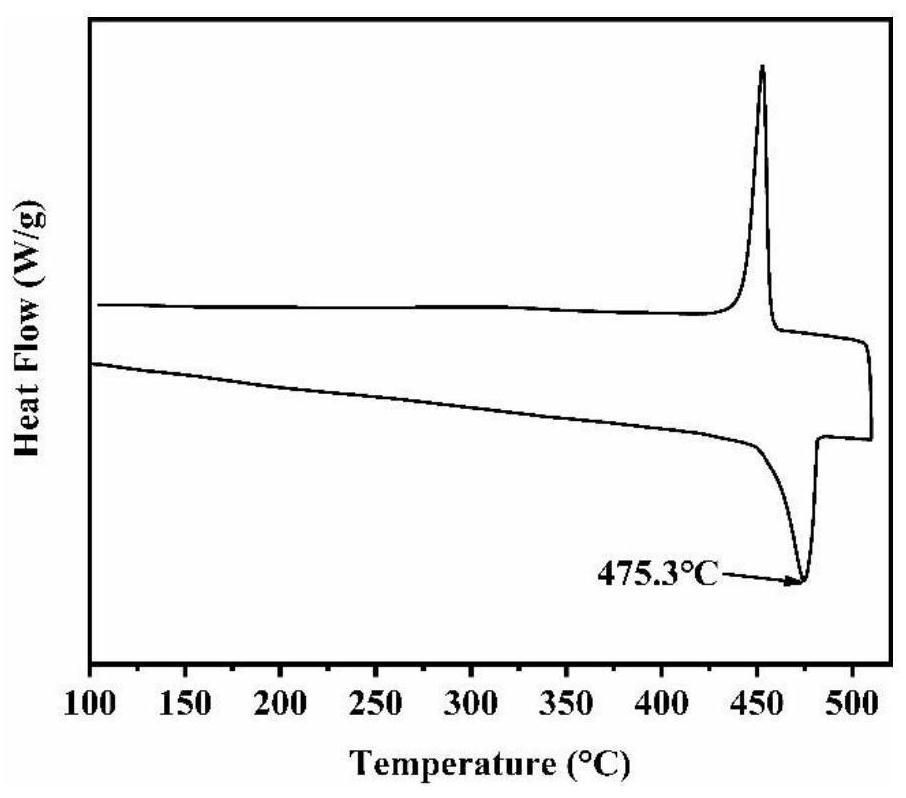

[0040] Under the protection of nitrogen atmosphere, add 4575g sulfolane (solid content 10wt%), 1088mL toluene, 196.7g potassium carbonate, 24.4g cesium carbonate, 322.3g difluoromonomer 3 and 186g biphenyldiphenol successively to the polymerization reaction system, heat up To 140°C, azeotropically remove water, reflux for 2h, remove toluene in the reaction system by distillation, raise the temperature to 190°C-210°C for 6h, pour the reaction product into anhydrous methanol to wash, crush and dry to obtain the precursor , then dissolve the precursor in 4683mL DMF, add 585mL methanesulfonic acid solution with pH=0.1 to the solution after the precursor is completely dissolved, reflux for 24h, wash with ethanol and water, and dry to obtain crystalline full-linked Benzene polyether ether ketone (PEDEK), the intrinsic viscosity of PEDEK is 2.09dL / g, T m It is 416.8°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com