Pre-paved waterproof coiled material with high slippage resistance and preparation method of pre-paved waterproof coiled material

A waterproofing membrane, anti-slip technology, applied in chemical instruments and methods, mining equipment, shaft equipment, etc., can solve problems such as poor anti-slip, and achieve the effects of large adhesion, excellent mechanical properties, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

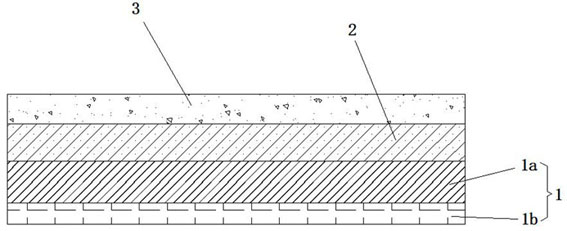

[0069] The high anti-slip pre-paved waterproof membrane of the present embodiment, such as figure 1 As shown, it includes a substrate layer 1, an adhesive layer 2 and a release layer 3 that are stacked in sequence. The substrate layer 1 includes an upper layer 1a and a lower layer 1b, and the upper layer 1a and the lower layer 1b are co-extruded from the first material and the second material. prepared, of which,

[0070] The raw material formula of the first material of the upper layer 1a is shown in Table 1.

[0071] Table 1 is the raw material formula (by mass parts) of the first material of the upper layer

[0072]

[0073] The raw material formula of the second material of the lower layer 1b is shown in Table 2.

[0074] Table 2 is the raw material formula (by mass parts) of the second material of the lower layer

[0075]

[0076] The high anti-slip pre-paved waterproof membrane in this example is prepared by the following method:

[0077] (1) The upper layer 1a...

Embodiment 2

[0086] The structure of the high anti-slip pre-paved waterproof membrane of this embodiment is the same as that of Example 1. In the pre-paved waterproof membrane, except that the raw material formula of the lower layer of the substrate layer is different from that of Example 1, the rest of the layers (including the upper layer, The raw material formula of adhesive layer and release layer) is all the same as embodiment 1, and the preparation method of each layer is also the same as embodiment 1.

[0087] In this example, the raw material formula of the second material of the lower layer is shown in Table 3.

[0088] Table 3 is the raw material formula of the second material of the lower layer of embodiment 2

[0089]

Embodiment 3

[0091] The structure of the high anti-slip pre-paved waterproof membrane of this embodiment is the same as that of Example 1. In the pre-paved waterproof membrane, except that the raw material formula of the lower layer of the base material layer is different from that of Example 1, the rest of the layers (including the base material) The raw material formula of the upper layer of the layer, the adhesive layer and the anti-adhesive layer) is all the same as that of Example 1, and the preparation method of each layer is also the same as that of Example 1.

[0092] In this example, the raw material formula of the second material of the lower layer is shown in Table 4.

[0093] Table 4 is the raw material formula of the second material of the lower layer of embodiment 3

[0094]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com