Aluminium foil surface passivation treatment process and aluminium plastic film

A technology of passivation treatment and aluminum foil, applied in metal material coating technology, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as increased energy consumption, decreased yield of aluminum foil, and increased production costs, and achieves It has corrosion resistance and tensile properties, reduces the chance of equipment being corroded, and improves passivation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

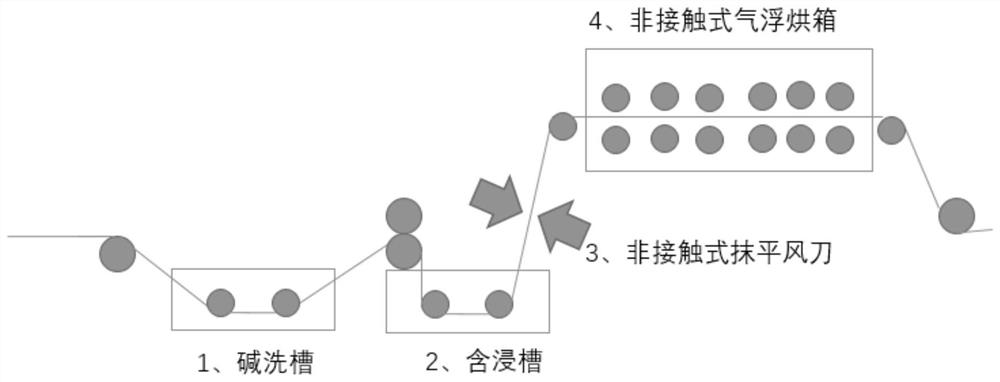

Method used

Image

Examples

Embodiment 1

[0039] In this example, 200 g of zirconium acetate, 400 g of acrylamide-modified acrylic resin, and 20 g of sodium bifluoride were dissolved in pure water and fixed to 40 L to obtain a zirconium passivation solution. The passivation solution was placed in a passivation tank, and 4000 The rice aluminum foil is processed and rolled by the above-mentioned self-developed equipment, and the processing time and aluminum foil yield are counted.

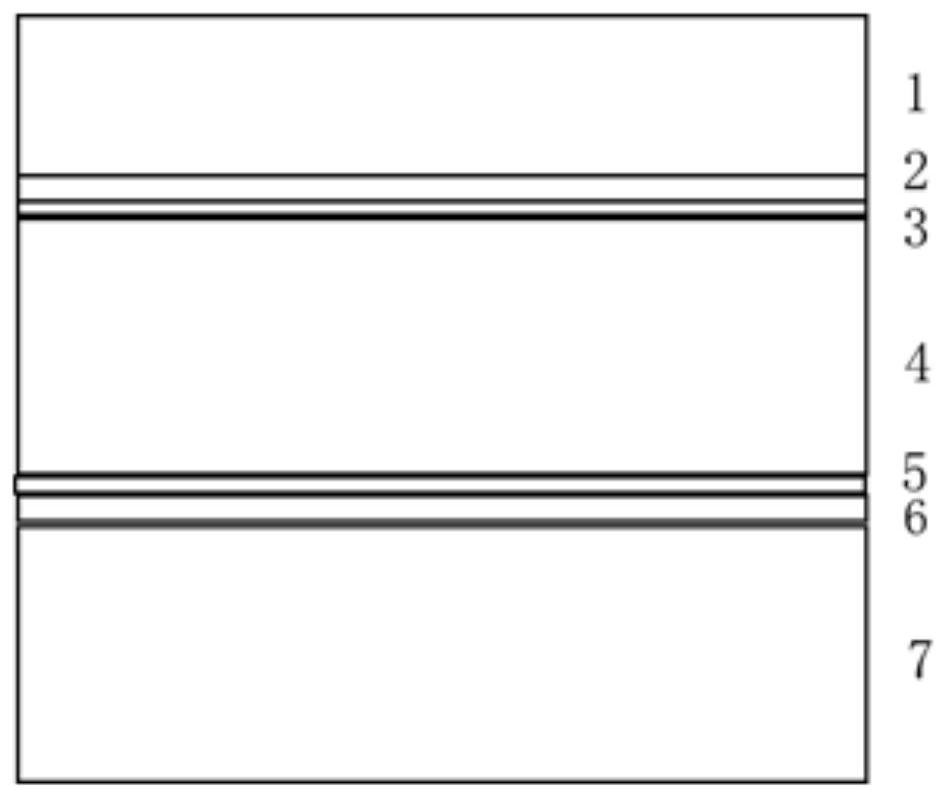

[0040] The aluminum foil which has undergone surface passivation treatment is thermally bonded with nylon and CPP through the outer layer glue and the inner layer glue to obtain the aluminum plastic film.

[0041] The obtained passivated aluminum foil samples were subjected to a salt spray resistance test according to ASTM B117.

[0042] The obtained aluminum-plastic film was cut into a sample strip with a width of 15 mm, and the mechanical properties of the sample strip were tested to obtain the initial tensile force of the aluminum foil an...

Embodiment 2

[0045] In this example, 400 g of zirconium acetate, 200 g of acrylamide-modified acrylic resin, and 40 g of sodium bifluoride were dissolved in pure water and fixed to 40 L to obtain a zirconium passivation solution, and the chromium-free passivator was placed in the passivation tank. 4,000 meters of aluminum foil was processed and rolled by traditional roller coating equipment, and the processing time and aluminum foil yield were counted.

[0046] The aluminum foil which has undergone surface passivation treatment is thermally bonded with nylon and CPP through the outer layer glue and the inner layer glue to obtain the aluminum plastic film.

[0047] The obtained passivated aluminum foil samples were subjected to a salt spray resistance test according to ASTM B117.

[0048] The obtained aluminum-plastic film was cut into a sample strip with a width of 15 mm, and the mechanical properties of the sample strip were tested to obtain the initial tensile force of the aluminum foil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com