Preparation equipment and preparation method of sputtering target material

A technology for sputtering target materials and equipment, which is applied to the preparation equipment of sputtering target materials and the field of preparation thereof, can solve the problems of non-dense structure, preparation of blanks, and difficulty in effectively controlling oxygen content, and achieves the reduction of impurities and impurity content. Increase, reduce the increase of impurity content, the effect of preventing impurity pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

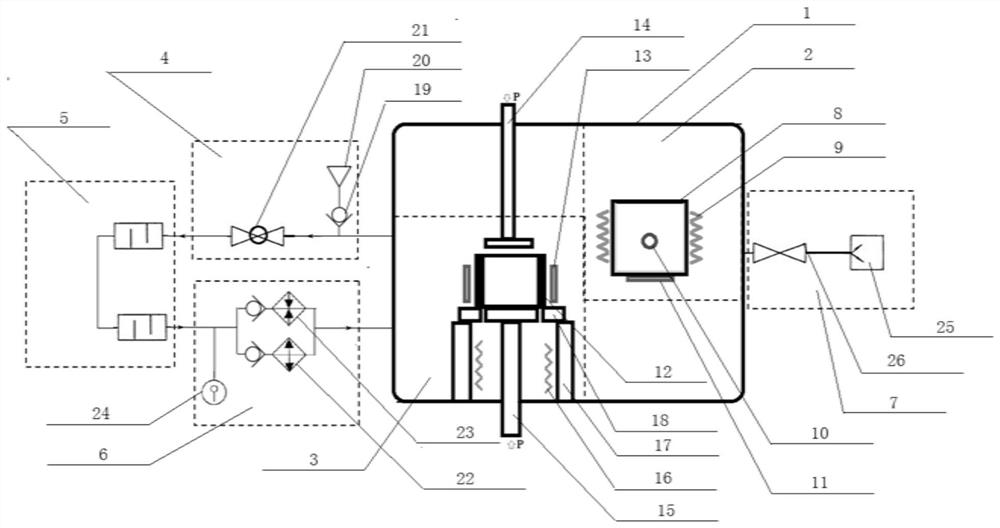

[0068] A high-purity metal material smelting equipment, which includes a closed cavity 1, a smelting and pouring device 2, a casting and molding device 3, an atmosphere treatment device and other auxiliary facilities to ensure the normal operation of the equipment; wherein the smelting and pouring device 2 and the casting and molding device 3 In the closed cavity, the atmosphere treatment device is composed of a circulating atmosphere device 4, an atmosphere cleaning device 5, an atmosphere temperature control device 6 and a vacuum extraction device 7, which are connected to the closed cavity and provide a protective atmosphere.

[0069]The smelting and pouring device consists of four parts: a crucible 8, a smelting heating device 9, a crucible rotating device 10 and a melt stirring device 11, wherein:

[0070] The smelting heating device 9 is a high-frequency induction coil heating device, the melt stirring device 11 is an electromagnetic stirrer device, the crucible is a wate...

Embodiment 2

[0080] The slab mold is a conventional carbon steel mould. The slab mold 12 is not cooled by circulating cooling water. After the melt is poured into the mould, it is normally cooled by a protective atmosphere; the slab heat preservation device 16 is heated by resistance wire, and the rated temperature is ≤ 900°C, temperature accuracy ±5°C; Other devices are the same as in Embodiment 1.

[0081] Through this set of equipment, pure cerium is smelted and pressure cast. The raw material is high-purity cerium with a purity of ≥99.995%. After adding raw materials into the crucible, the atmosphere in the chamber is pre-evacuated by a vacuum pump, so that the vacuum degree in the furnace is 5×10 -3 Below Pa, then fill it with high-purity argon, so that the air pressure in the cavity is 800mbar, and the oxygen partial pressure is less than 0.0001Pa; the raw material is heated by high-frequency induction until it is fully melted, and kept for 10 minutes, and the melt is electromagnet...

Embodiment 3

[0083] The slab mold is a heat-resistant (600°C) stainless steel mold, the slab mold 12 is not cooled by circulating cooling water, and is normally cooled by a protective atmosphere after the melt is poured into the mould; the slab heat preservation device 16 is heated by resistance wire Mode, rated temperature ≤ 1300 ℃, temperature accuracy ± 5 ℃;. Other devices are the same as in Embodiment 1.

[0084] Through this set of equipment, the Al-50Sc alloy is smelted and pressure-cast. The raw materials are high-purity aluminum and high-purity scandium, the purity of which is ≥99.995%. After adding raw materials into the crucible, the atmosphere in the chamber is pre-evacuated by a vacuum pump, so that the vacuum degree in the furnace is 5×10 -3 Below Pa, then fill it with high-purity argon, so that the air pressure in the cavity is 800mbar, and the oxygen partial pressure is less than 0.0001Pa; the raw material is heated by high-frequency induction until it is fully melted, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com