Wax type 3D material and preparation method and application thereof

A molding material and 3D technology, applied in the field of 3D printing, can solve problems such as easy plugging, high volume shrinkage, plugging, etc., and achieve the effect of cost reduction and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] In one of the embodiments, the preparation method of the refined paraffin comprises the following steps:

[0066] Using paraffin wax with a melting point of 60°C to 70°C and an oil content of less than 2.0% as raw material, carry out primary distillation at 240°C to 250°C and a vacuum of 150Pa to 300Pa to collect the residue;

[0067] Under the conditions of 250° C. to 260° C. and a vacuum of 50 Pa to 100 Pa, the residue is subjected to secondary distillation, and the evaporated product is collected.

[0068] Use low-cost paraffin as raw material, refine and purify it, reduce the content of components with melting point lower than 65°C and higher than 68°C, narrow the carbon distribution of the refined product, and narrow the melting range, which is beneficial to molding materials It cools rapidly from flowing liquid to solid, and is harder than ordinary paraffin, endowing molding materials with strong rigidity. Avoid excessively high melting point, blockage of the noz...

Embodiment 1

[0101] This embodiment provides a molding material in a wax-type 3D material and a preparation method thereof.

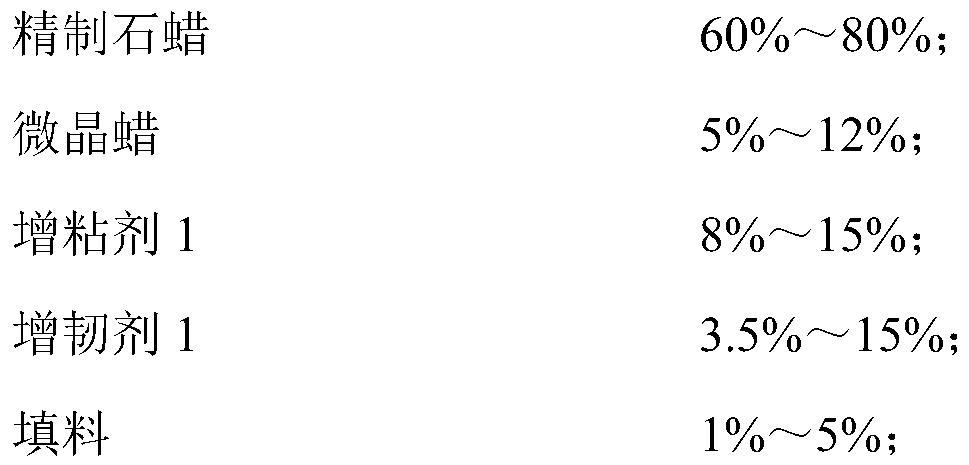

[0102] (1) The molding material in the wax-type 3D material provided in this embodiment is prepared from the following raw materials in mass percentage:

[0103]

[0104] The preparation method of described refined paraffin is as follows:

[0105] Using paraffin wax with a melting point of 60.8°C and an oil content of 1.8% as raw material, it is heated and melted, and sent to a first-stage molecular distillation device. By controlling the temperature at 240°C and the vacuum degree of 150Pa, low-component substances, water and air are evaporated, and the untreated oil is collected. The evaporated material is transported to the secondary molecular distillation device, and the evaporated material is collected by controlling the temperature at 250°C and the vacuum degree of 50Pa, which is the refined paraffin wax. Among them, hydrocarbons with 28 to 32 carbon atoms a...

Embodiment 2

[0111] This embodiment provides a molding material in a wax-type 3D material and a preparation method thereof.

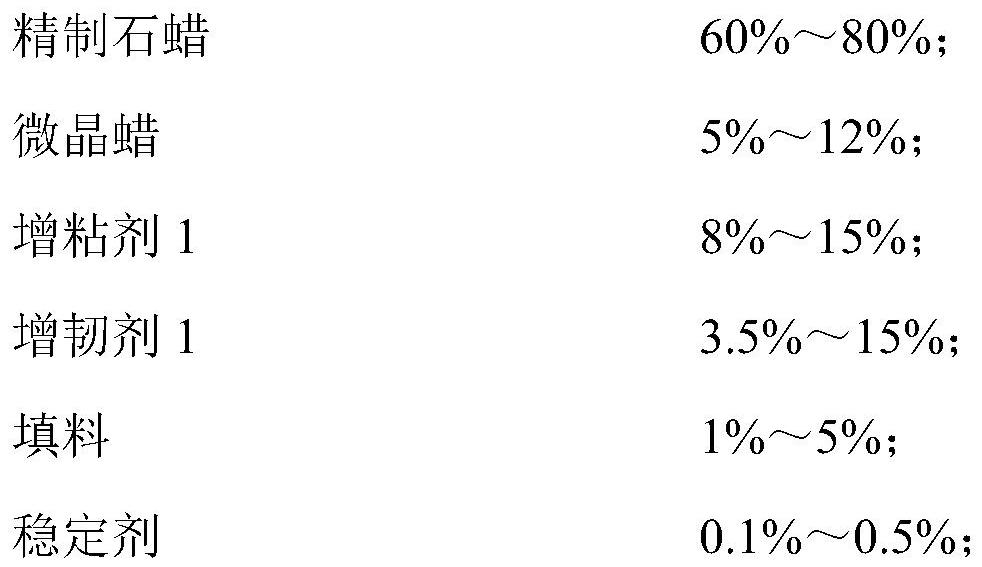

[0112] (1) The molding material in the wax-type 3D material provided in this embodiment is prepared from the following raw materials in mass percentage:

[0113]

[0114] The preparation method of described refined paraffin is as follows:

[0115] Using paraffin wax with a melting point of 64.9°C and an oil content of 1.0% as raw material, it is heated and melted, and sent to a first-stage molecular distillation device. By controlling the temperature at 250°C and the degree of vacuum at 300Pa, low-component substances, water and air are evaporated, and the untreated oil is collected. The evaporated material is transported to the secondary molecular distillation device, and the evaporated material is collected by controlling the temperature at 260°C and the vacuum degree of 100Pa, which is the refined paraffin wax. Among them, hydrocarbons with 28 to 32 carbon ato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com