Heteroatom-resistant combustion catalyst as well as preparation method and application thereof

A technology of combustion catalysts and heteroatoms, applied in the direction of combustion methods, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve problems such as inability to run stably for a long time, inability to apply waste gas treatment, and strong resistance to chlorine poisoning. Achieve high catalytic activity and stability, low manufacturing cost, good sulfur and halogen resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

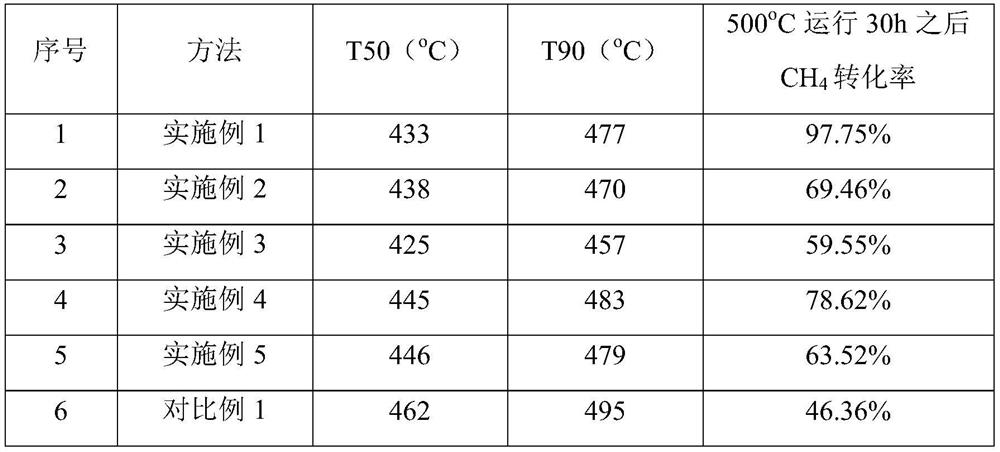

Examples

Embodiment 1

[0061] Preparation of composite oxide C1

[0062] Weigh 29.4g of nine-fold aluminum nitrate and dissolve it in 150ml deionized water to obtain solution A1, weigh 5.27g of nine-fold chromium nitrate and dissolve it in 50ml of deionized water to obtain solution B1, mix solutions A1 and B1, and stir for 2h. Heat the mixed solution to 70°C, add concentrated ammonia water (concentration: 25%) dropwise until the pH value of the solution reaches 8, reflux for 12 hours (reflux temperature is 50°C), and put the mixed solution at a temperature of 20°C and a relative humidity range (10~ 95%) for 24 hours, filtered and washed with deionized water for 3 times, dried at 120°C for 24 hours, and calcined at 600°C for 4 hours to obtain a composite oxide;

[0063] Preparation of coating slurry D1

[0064] The composite oxide C1 (5g, composite oxide Al 2 o 3 with Cr 2 o 3 Mass ratio 1:0.25), the concentrated nitric acid of the pseudo-boehmite of 0.8g, 0.1ml joins 30ml deionized water, joins...

Embodiment 2

[0069] Preparation of composite oxide C2

[0070] Weigh 23.5g of Jiuheshui aluminum nitrate and dissolve it in 150ml deionized water to obtain solution A2, weigh 2.02g of Liuheshui cerium nitrate and dissolve it in 50ml of deionized water to obtain solution B2, mix solutions A2 and B2, stir for 2h, and The mixed solution was heated to 80°C, and concentrated ammonia water (concentration: 25%) was added dropwise until the pH value of the solution reached 9, refluxed for 8 hours (reflux temperature was 50°C), and the mixed solution was kept at a temperature of 20°C and a relative humidity range (10-95 %) standing in the environment for aging for 24 hours, filtering and washing with deionized water for 3 times, drying at 120°C for 24 hours, and roasting at 600°C for 4 hours to obtain composite oxide C2;

[0071] Preparation of coating slurry D2

[0072] The composite oxide C2 (4g, composite oxide Al 2 o 3 with CeO 2 Mass ratio 1:0.25), the concentrated nitric acid of the pseud...

Embodiment 3

[0077] Preparation of composite oxide C3

[0078] Weigh 23.5g of nonaqueous aluminum nitrate and dissolve it in 150ml of deionized water to obtain solution A3, weigh 2.78g of pentahydric zirconium nitrate and dissolve it in 50ml of deionized water to obtain solution B3, mix solutions A3 and B3, and stir for 2h. The mixed solution was heated to 80°C, and concentrated ammonia water (25% concentration) was added dropwise until the pH value of the solution reached 9, refluxed for 8 hours (reflux temperature was 50°C), aged at room temperature for 24 hours, filtered and washed 3 times with deionized water, Dry at 120°C for 24 hours, and bake at 600°C for 4 hours to obtain composite oxide C3;

[0079] Preparation of coating slurry D3

[0080] Composite oxide C3 (4g, composite oxide Al 2 o 3 with ZrO 2 Mass ratio 1:0.25), the concentrated nitric acid of the pseudo-boehmite of 0.6g, 0.1ml joins in 24ml deionized water, joins this mixture in the ball mill jar, under 500 revs / min of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com