Method for preparing conjugated microporous polymer TiO2 composite nano antibacterial agent by in-situ method

A nano-antibacterial agent and conjugated micropore technology, which is applied in the field of in-situ preparation of conjugated microporous polymer TiO2 composite nano-antibacterial agent, can solve the problems of accelerated bacterial inactivation, bacterial inactivation, and low solar energy utilization rate. Achieve the effects of accelerating bacterial inactivation, widening the band gap, and improving photocatalytic antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

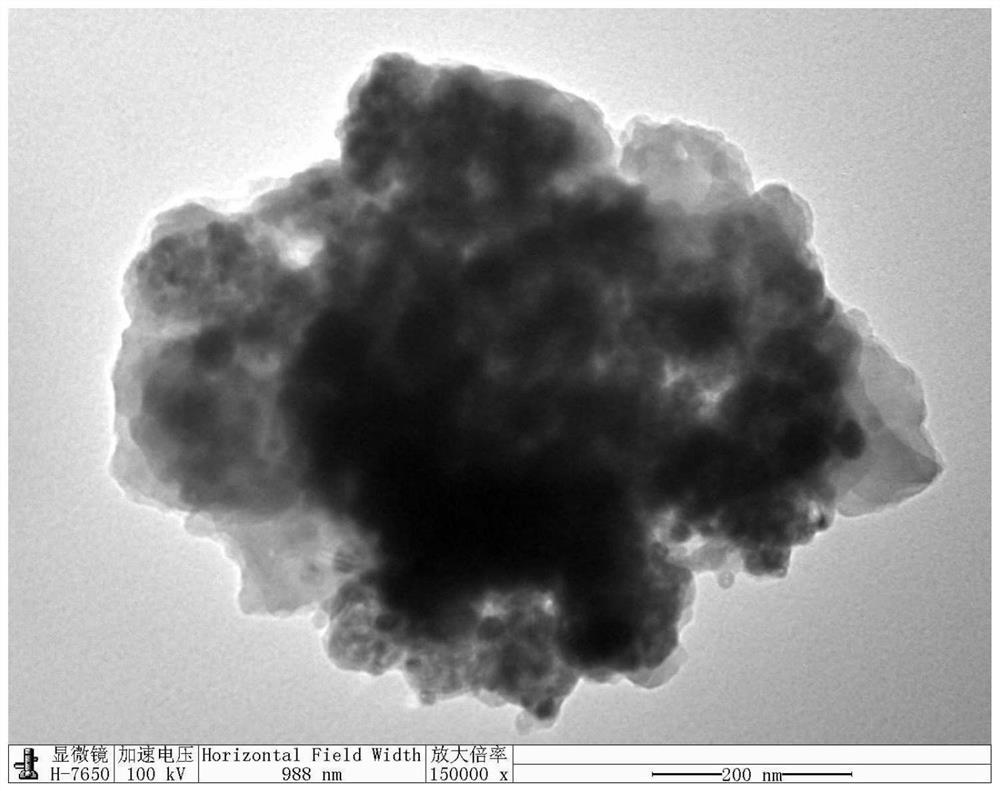

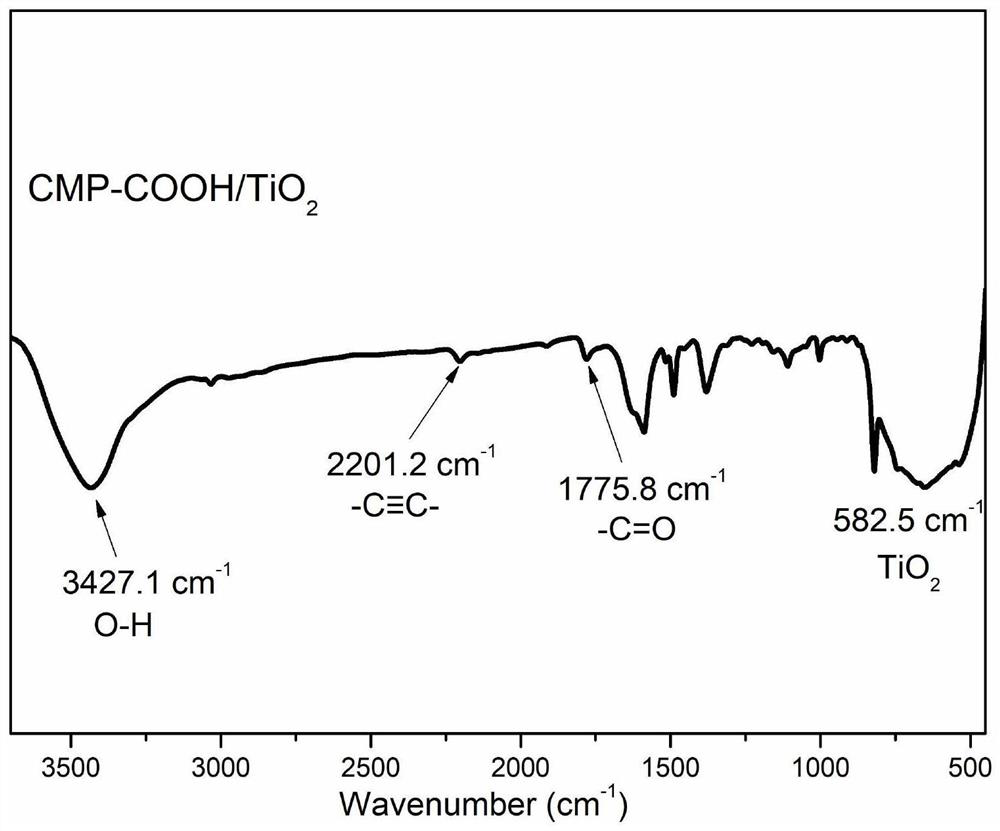

[0033] see Figure 1-2 , the invention provides a conjugated microporous polymer TiO 2 The preparation method of composite nano antibacterial agent comprises the following steps:

[0034] S1. Ultrasonic dispersion of TiO in toluene 2 particles to disperse evenly.

[0035] S2. Preparation of conjugated microporous polymer / TiO 2 Composite nano antibacterial agent

[0036] S21, take 4,4'-diethynyl biphenyl, 2,4,6-tribromobenzoic acid, CuI, Pd(PPh 3 ) 2 Cl 2 and PPh 3 Placed in a three-necked flask; 4,4'-diethynyl biphenyl, 2,4,6-tribromobenzoic acid, CuI, Pd(PPh 3 ) 2 Cl 2 、PPh 3 and TiO 2 The mixing mass ratio is 20-22:24-26:1:2-4:12-14:350-450; the specific preferred mass ratio is 21:25:1:3:13:400, combining 4,4'- Diethynyl biphenyl with functional monomers having carboxyl groups and TiO 2 One-pot fabrication of conjugated microporous polymer / TiO by in situ polymerization 2 Composite nano antibacterial agent, wherein, the total mass of 4,4'-diethynyl biphenyl and...

Embodiment 1

[0042] (1) Take TiO 2 (4390mg, 54.94mmol) was added to a beaker containing 20mL of toluene, and ultrasonically oscillated for 1h.

[0043] (2) Take 4,4'-diethynylbiphenyl (202mg, 1.00mmol), 2,4,6-tribromobenzoic acid (239mg, 0.67mmol), CuI (9.52mg, 50μmol), Pd(PPh 3 ) 2 Cl 2 (35.12 mg, 100 μmol) and PPh 3 (131mg, 500μmol) was placed in a 250ml three-necked bottle.

[0044] (3) Under the protection of nitrogen, inject toluene (10.00mL) and triethylamine (15.00mL) into (2), and add the mixture in (1) in (2), stir well, and the mixture is heated to 85°C, and stirred at 85°C for 36 hours to obtain a mixed solid powder.

[0045] (4) The solid powder obtained in (3) was washed three times with chloroform, toluene and saturated potassium iodide aqueous solution respectively, and then the solid powder was Soxhlet-extracted for 72 hours with dichloromethane as a solvent.

[0046] (5) Dry the solid powder extracted from (4) at 50°C for 12 hours to constant weight to obtain a conju...

Embodiment 2

[0048] (1) Take TiO 2 (4190mg, 49.94mmol) was added into a beaker containing 20mL of toluene, and ultrasonically oscillated for 2h.

[0049] (2) Take 4,4'-diethynylbiphenyl (180mg, 0.80mmol), 2,4,6-tribromobenzoic acid (190mg, 0.465mmol), CuI (7.52mg, 40μmol), Pd(PPh 3 ) 2 Cl 2 (45.12mg, 80μmol) and PPh 3 (120mg, 450μmol) was placed in a 250ml three-necked bottle.

[0050] (3) Under the protection of nitrogen, inject toluene (8.00mL) and triethylamine (13.00mL) into (2), and add the mixture in (1) in (2), stir well, the mixture is heated to 85°C and stirred at 90°C for 36 hours to obtain a mixed solid powder.

[0051] (4) The solid powder obtained in (3) was washed three times with chloroform, toluene and saturated potassium iodide aqueous solution respectively, and then the solid powder was Soxhlet-extracted for 72 hours with dichloromethane as a solvent.

[0052] (5) Dry the solid powder extracted from (4) at 50°C for 12 hours to constant weight to obtain a conjugated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com