Production process of silicon carbide titanium

A production process, silicon carbide titanium technology, applied in the chemical industry, carbon compounds, inorganic chemistry, etc., can solve the problems of easy formation of heterogeneous phases, complex production process, high temperature and high sintering requirements, low temperature requirements and good product purity , the effect of easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

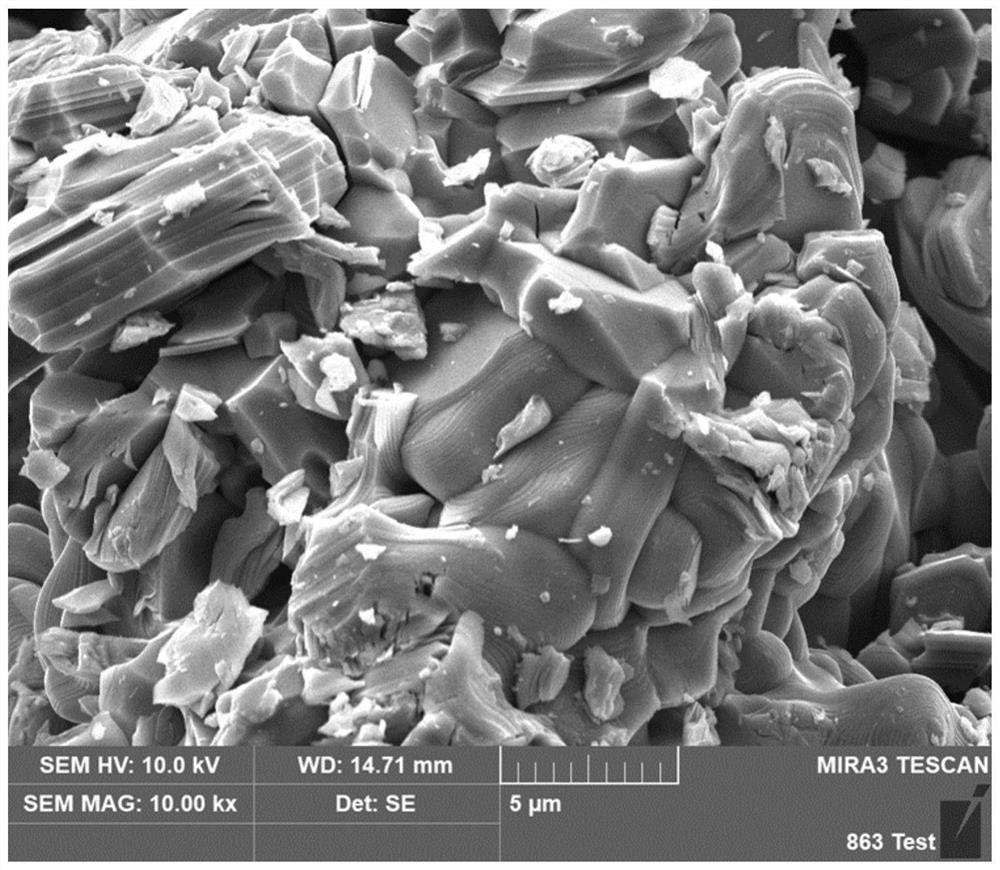

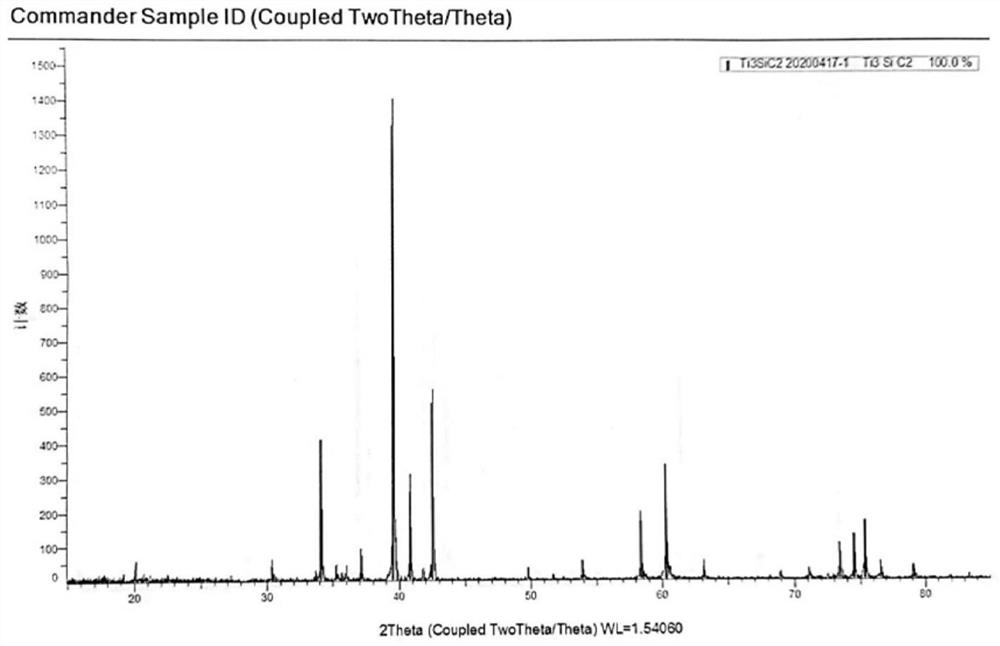

Image

Examples

Embodiment 1

[0029] (1) Selection of raw materials

[0030] The purity of titanium sponge is 99.8%, and the particle size is 3mm-25mm; the purity of monocrystalline silicon is 99.999%, and the particle size is 0-10mm; the purity of high-purity graphite is 99.99%, and the particle size is 300 mesh;

[0031] Put 8.36kg of titanium sponge and 1.64kg of monocrystalline silicon into a graphite crucible (with a boron nitride coating inside the graphite crucible) in a 25 kg vacuum induction melting furnace, vacuumize to 5Pa-10Pa, and heat up with power transmission. 90kw, continue to heat up until the sponge titanium and single crystal silicon are remelted, stop vacuuming; fill with argon to a negative pressure of 0.05Pa, turn on electronic stirring, stirring time is 15 minutes, to ensure that titanium and silicon are fully melted and alloyed, pouring mold, cut off the power supply and cool for 5 hours, and then come out of the furnace to obtain a titanium-silicon alloy ingot;

[0032] (2) The o...

Embodiment 2

[0036] (1) Selection of raw materials

[0037] The purity of titanium sponge is 99.8%, and the particle size is 3mm-25mm; the purity of monocrystalline silicon is 99.999%, and the particle size is 0-10mm; the purity of high-purity graphite is 99.99%, and the particle size is 300 mesh;

[0038] 10.04kg of titanium sponge and 1.96kg of monocrystalline silicon are packed into a graphite crucible (the interior of the graphite crucible is painted with boron nitride coating) in a 25 kg vacuum induction melting furnace; the vacuum is pumped to 5Pa-10Pa, and the temperature is raised by power transmission. 90kw, continue to heat up until the sponge titanium and single crystal silicon are remelted, stop vacuuming; fill with argon to a negative pressure of 0.09Pa, start electronic stirring, stirring time is 18 minutes, to ensure that titanium and silicon are fully melted and alloyed, pouring mold, cut off the power supply and cool for 5.5 hours, and then come out of the furnace to obtai...

Embodiment 3

[0043] (1) Selection of raw materials

[0044] The purity of titanium sponge is 99.8%, and the particle size is 3mm-25mm; the purity of monocrystalline silicon is 99.999%, and the particle size is 0-10mm; the purity of high-purity graphite is 99.99%, and the particle size is 300 mesh;

[0045] 12.55kg of titanium sponge and 2.45kg of monocrystalline silicon are packed into a graphite crucible (the interior of the graphite crucible is painted with boron nitride coating) in a 25 kg vacuum induction melting furnace; the vacuum is evacuated to 5Pa-10Pa, and the temperature is raised by power transmission. 90kw, continue to heat up until the sponge titanium and single crystal silicon are remelted, stop vacuuming; fill with argon to a negative pressure of 0.08Pa, turn on electronic stirring, stirring time is 20 minutes, to ensure that titanium and silicon are fully melted and alloyed, pouring mold, cut off the power supply and cool for 6 hours, and then come out of the furnace to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com