Preparation method of perfluorohexyl propyl acrylate and application of the perfluorohexyl propyl acrylate in fabric waterproof and oil-proof agent

A technology of fluorohexylpropyl acrylate and perfluoroalkylethylene, which is applied in the field of fluorine-containing acrylate preparation, can solve the problems of long reaction time, unfavorable long-term large-scale industrial production, high requirements for reaction conditions, etc., and achieve good water and oil resistance Effect, strong emulsification system, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

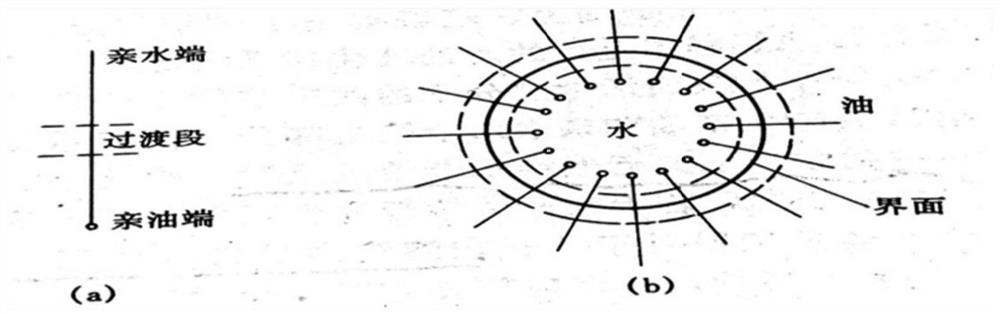

Image

Examples

preparation example Construction

[0021] First, the invention provides a kind of preparation method of perfluorohexyl propyl acrylate, comprising the steps:

[0022] S1 Perfluoroalkylethylene and methanol undergo free radical addition reaction under the triggering action of organic peroxide. The molar ratios of perfluoroalkylethylene to methanol and organic peroxide are 1:20 and 1:0.02, respectively. The reaction pressure is 1.0-2MPa, the temperature is 80°C, and the time is 3h; after the reaction, the first vacuum distillation purification is carried out to obtain perfluoroalkyl ethyl propanol;

[0023] S2 Dissolve the perfluoroalkyl ethyl propanol in S1 in tert-butanol, and carry out esterification reaction with excess acrylic acid under the action of a catalyst. The reaction temperature is 70-100°C, and the reaction time is 2-8h. After the reaction, the tert-butanol was recovered, and then purified by the second vacuum distillation to obtain perfluorohexylpropyl acrylate.

[0024] In the present invention,...

Embodiment 1

[0043] S1 Add 692g of perfluorohexylethylene (2mol), 1280g of methanol (40mol) and 4.72g of acetyl peroxide (0.04mol) into a high-pressure stainless steel reactor with a capacity of 5L, and seal the reactor. The high-pressure stainless steel reactor is equipped with electric stirrer, thermocouple, cooling coil and shaft seal cooling water. Start the stirring process, raise the temperature to 80°C, react for 3 hours under a pressure of 1.2-2MPa, cool to room temperature and discharge to obtain the crude product of perfluorohexylpropanol. Under the system pressure of -0.1MPa~-0.096MPa and temperature of 80~180°C, the crude product was purified by vacuum distillation to obtain 706g of colorless and transparent perfluorohexylpropanol, the purity of which was detected by gas chromatography was 96.10%. The rate is 89.74%.

[0044] S2 Add 779g of purified perfluorohexylpropanol (2mol) and 2L of tert-butanol to a glass reactor with a capacity of 5L and stir for 2min, then add 288g of...

Embodiment 2

[0046]S1 Add 692g of perfluorohexylethylene (2mol), 1280g of methanol (40mol) and 4.72g of acetyl peroxide (0.04mol) into a high-pressure stainless steel reactor with a capacity of 5L, and seal the reactor. The high-pressure stainless steel reactor is equipped with electric stirrer, thermocouple, cooling coil and shaft seal cooling water. Start the stirring process, raise the temperature to 80°C, react for 3 hours under a pressure of 1.2-2MPa, cool to room temperature and discharge to obtain the crude product of perfluorohexylpropanol. Under the system pressure of -0.1MPa~-0.096MPa and temperature of 80~180°C, the crude product was purified by vacuum distillation to obtain 706g of colorless and transparent perfluorohexylpropanol, the purity of which was detected by gas chromatography was 96.10%. The rate is 89.74%.

[0047] S2 Add 779g of purified perfluorohexylpropanol (2mol) and 2L of tert-butanol to a glass reactor with a capacity of 5L and stir for 2min, then add 288g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com