Method for harmlessly treating arsenic in arsenic-containing waste liquid

A technology of waste liquid and arsenic precipitation, which is applied in the fields of chemical instruments and methods, metallurgical wastewater treatment, arsenate/arsenite, etc., can solve the problems that affect the leaching toxicity stability of mixed arsenic slag, high acidity of scorodite precipitation, Solve the problems of large amount of scorodite mixed slag, etc., to achieve the effect of reducing the amount of arsenic fixation solution, economical treatment cost, and low risk of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

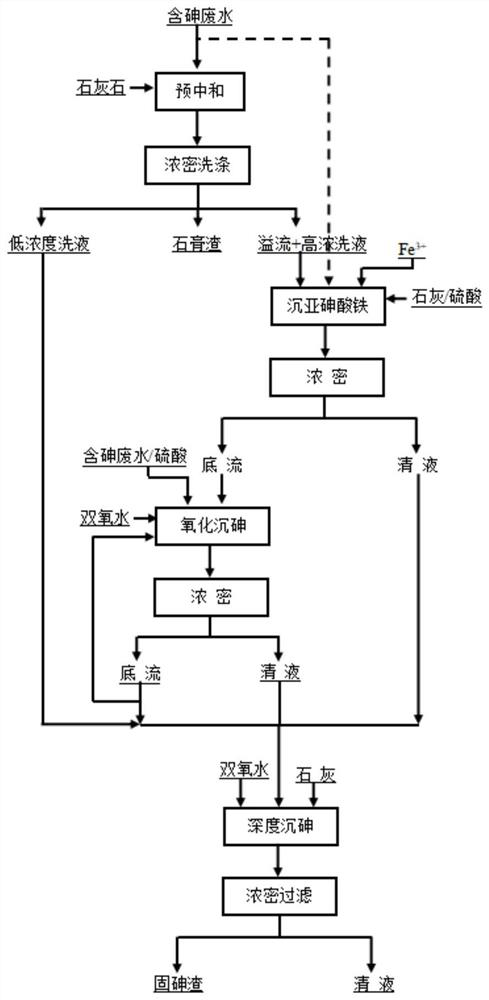

[0027] This embodiment provides a method for harmless arsenic disposal of arsenic-containing waste liquid. The arsenic-containing waste liquid contains 8.86 g / L of arsenic and 68 g / L of sulfuric acid. Such as figure 1 shown, including the following steps:

[0028] 1) Pre-neutralization: add limestone to the arsenic-containing waste liquid for pre-neutralization, control the terminal acidity to 15g / L, filter the neutralized pulp to obtain a mixture of gypsum slag and high arsenic, and wash the gypsum slag to obtain a low-arsenic wash liquid;

[0029] 2) Precipitation of ferric arsenite: add ferric sulfate to the high-arsenic mixture, control the molar ratio of iron to arsenic to 1.2:1, after complete dissolution, add milk of lime to neutralize to pH 7.0, and precipitate ferric arsenite; carry out thickening to obtain Low arsenic overflow liquid and iron arsenite underflow with a mass concentration of 30%;

[0030] 3) Precipitation of arsenic by oxidation: Add concentrated su...

Embodiment 2

[0037] This embodiment provides a method for arsenic harmless disposal of arsenic-containing waste liquid. The arsenic-containing waste liquid contains 28.6 g / L of arsenic and 192 g / L of sulfuric acid. Such as figure 1 shown, including the following steps:

[0038] 1) Pre-neutralization: Add arsenic-containing waste liquid to limestone for pre-neutralization, control the end-point acidity to 20g / L, filter the neutralized pulp to obtain gypsum slag and high-arsenic mixed liquid, and wash the gypsum slag to obtain low-arsenic lotion ;

[0039] 2) Ferric arsenite precipitation: add ferric sulfate solution to the high-arsenic mixture, and control the molar ratio of iron to arsenic to 1.5:1; after complete dissolution, add milk of lime, neutralize to pH 5.0, and then thicken to obtain low Arsenic overflow liquid and iron arsenite underflow with a mass concentration of 25%;

[0040] 3) Precipitation of arsenic by oxidation: add the arsenic-containing waste liquid of this example ...

Embodiment 3

[0047] This embodiment provides a method for harmless arsenic disposal of arsenic-containing waste liquid, wherein the arsenic-containing waste liquid contains 0.5 g / L of arsenic and 25 g / L of sulfuric acid. Such as figure 1 shown, including the following steps:

[0048] 1) Pre-neutralization: add limestone to the arsenic-containing waste liquid for pre-neutralization, control the terminal acidity to 10g / L, filter and wash the neutralized pulp to obtain gypsum slag and arsenic-containing solution;

[0049] 2) Precipitated iron arsenite: ferric sulfate is added to the arsenic-containing solution according to the molar ratio of iron to arsenic 1.3:1. After it is completely dissolved, add milk of lime to neutralize to a pH value of 7.0, and then thicken to obtain a low-arsenic overflow solution and quality 23% ferrous arsenite underflow;

[0050] 3) Precipitation of arsenic by oxidation: add concentrated sulfuric acid to the underflow of ferric arsenite, stir to dissolve, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com